Your 1987 Dodge truck will have had a computer controlled carburetor and ignition system. The computer requires a manifold vacuum feed to the computer to correctly determine where the timing should be in any given condition. If you replaced the carburetor with a non-computer carburetor, you likely removed this vacuum feed and now the computer has lost that vital input. While it is possible to keep the lean burn ignition working after switching the carburetor to a non-computer controlled carb, you have to know what you are doing to make it work. I suspect what has happened is parts of the lean burn system have been removed (such as the manifold vacuum feed for the computer) which have lead to incorrect ignition timing.

Your post presents several problems, and I will do my best to help you answer each of them.

(A) How to check for timing chain stretch.

(1) Find the timing marks on the vibration dampener and the timing tab on the timing chain cover. Clean them and use white out or paint to mark TDC on the timing tab and the timing mark on the vibration dampener.

(2) Rotate the crankshaft by hand clockwise until the timing mark line up with TDC. Now turn the crankshaft one full revolution clockwise until the timing mark returns to TDC. The purpose of the second rotation is to ensure that all slack is taken out of the chain.

(3) Remove the distributor cap and set it out of the way so you have a clear view of the rotor. Now slowly rotate the crankshaft COUNTERCLOCKWISE and watch the rotor. Stop turning the crankshaft as soon as the rotor begins to move. If you are tall you can do this on your own, but you may need a friend to watch the rotor while you rotate the crank.

(4) Now look at where the timing mark on the vibration dampener is. If the timing mark is more than 2-5 degrees before the TDC mark, you need to replace your chain.

A timing chain can help diagnose a stretched chain by watching if the timing mark jumps around while the motor is running. The timing mark should be rock solid in the same place while the motor is running. If it is jumping all over then chances are the chain is stretched.

(B) Vibration dampener slippage

Slant six vibration dampeners are constructed by bonding a thick outer metal ring to a small inner ring with some kind of thick strong rubber. The inner ring presses onto the crankshaft. Over time (decades) the outer ring can slip on the rubber resulting in the timing mark on the outer ring no longer accurately reflecting the true position of the crankshaft.

It is fairly easy to check for vibration dampener slippage. The only special tool you need is a TDC stop tool, such as the one sold

HERE

To check your timing mark, remove the #1 spark plug and thread the tool into the hole. By hand, rotate the motor counterclockwise until the motor won't turn anymore (the piston has come into contact with the bottom of the TDC tool). Using whiteout, mark the vibration dampener next to the 0 degree or TDC line on the timing tab. Now rotate the motorclockwise until the mtor stops turning. Mark the vibration dampener again at the TDC mark on the timing tab.

Ideally, the two marks on the vibration dampener should be equidistant from the timing mark cast into the dampener. If the two marks are not equidistant, you need to measure the distance between the two, divide it by two, and make a new mark equally distanced from each whiteout mark which will be your new timing mark.

Alternatively, you can use the timing tab as a ruler and measure how far each whiteout mark is from the cast timing mark and then figure where the timing should be.

(C) Timing system malfunction

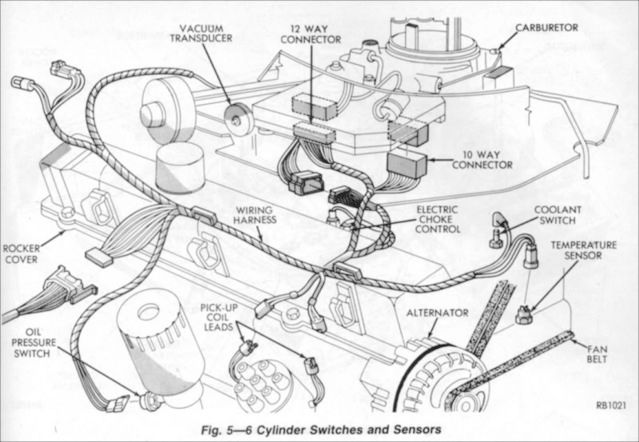

Here is a diagram of the sensors that make up the lean burn system:

Of critical importance to the operation of the computer controlled ignition system are the coolant temperature sensor and the vacuum transducer on the computer. As I mentioned above, the vacuum transducer on the computer MUST receive a MANIFOLD vacuum signal to operate properly. This is opposite what a non-computer controlled distributor vacuum advance needs. The computer must sense full manifold vacuum when the throttle is closed. This is typically achieved via a port on the carburetor.

I suspect that the two barrel carburetor you installed on your truck does not have a "full time" or "unported" vacuum signal and the vacuum hose for the computer is either unhooked or hooked up to the ported vacuum nipple on the carb. Either circumstance will wreak havoc with the computer controlled timing.

Even before you verify that your timing chain is not stretch and the timing mark has not slipped, I strongly recommend you (a) test that the vacuum transducer on the computer still holds a vacuum and (b) ensure that the transducer on the computer is hooked to a manifold vacuum source. If you have switch carburetors, the easiest manifold vacuum source to tap into is the vacuum operated choke pulloff on the carburetor. You can cut the existing hose on the carb and insert a T fitting. Run the hose from the computer to the extra nipple on the T fitting.

Next, make absolutely sure that the coolant temperature sensor is installed and the wire is hooked up to it.

Assuming the rest of the wiring is still in place and properly hooked up, if the vacuum transducer and the coolant temperature sensor are installed and operating correctly, the computer should still be able to control the timing properly.

******EDIT******

I just went back and reread your original post and saw that you removed all the wiring and the lean burn computer. If that is so, then (A) you are lucky the motor runs at all, and (B) your timing is now fixed at whatever your base timing is since the lean burn distributor has no provision for timing advance. Since that is the case, you really need to change to a different ignition system (but I am still confused as to how you are getting the ignition to fire if you removed the lean burn computer).

(4) Ultimate solution

In the end, it is actually cheaper and easier to bite the bullet and switch to an ignition system that is not controlled by the computer. Rather than take a HUGE step backwards to points ignition, I strongly recommend you actually take a step forward and swap to HEI ignition. Instructions on how to do the swap are contained

HERE.

If you can post some decent resolution pictures of what is left of the lean burn system on your motor, we can help you figure out the most effective and cost-efficient way to correct the poor running on your truck.

Incidentally, have you used a vacuum gauge to check your vacuum at idle?