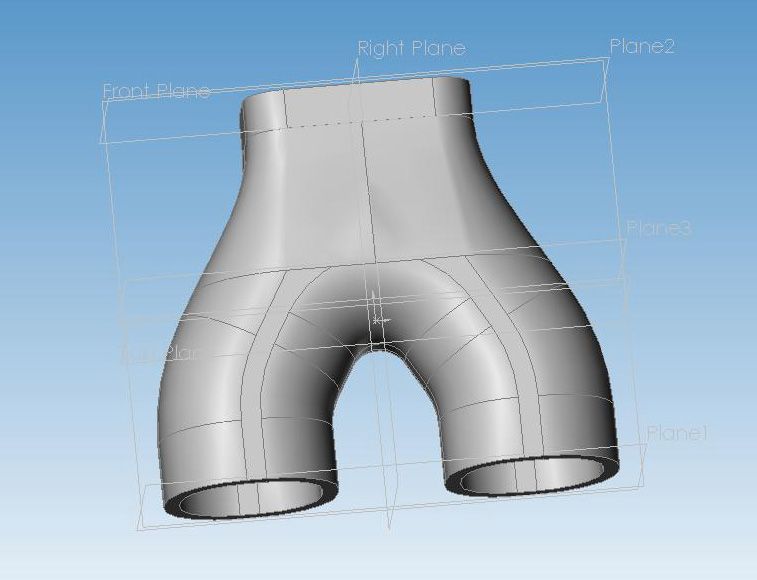

Not really an update on the EFI intake status, but more of an update to my toy arsenal. I recently got a 3D printer to help do prototyping of my many part designs before I make the casting patterns for them. My printer is capable of printing something as large as an entire 6 cylinder intake manifold and other parts of that length and size. The build bed is 16"x 16"x 9", or 22-5/8" across the diagonal. I can already see where I need to possibly add a second and maybe even a 3rd 3D printer just to fulfill the demand and prototyping volume I have. Here is a 3D model I created, and the Clifford intake I loosely based my design on and the sample 3D part I printed from it. All I can say is that everyone needs two or three of these laying around. There is no limit to what you can create with one.