Quote:

Somewhat off topic- how do you CC a head? I assume you get a piece of plexi and a gradated syringe (in CCs of course) and see how much water it takes to fill each combustion chamber? If you find discrepancies, how do you correct them?

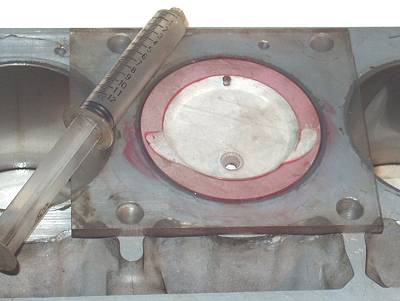

Yes, a plastic plate with a couple of holes (entrance and a vent hole) along with a syringe. I use alcohol mixed with a little ATF to give the fluid a red tint.Here is my set-up being used to check a piston dish.

The same process is used on a cylinder head chamber.

It is good to check all the chambers to see if a angled milling cut is needed. (cc increase as you go "down the line")

If one or two chambers have less volume, you need to grind material out to even them up to the others.

DD