Well, here is the plan-

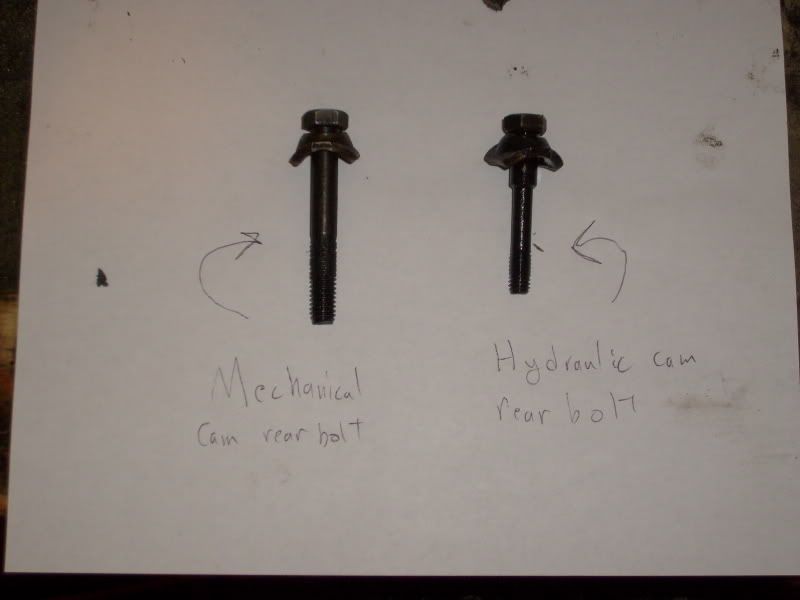

I am getting a free dead hydraulic slant from 6shotvanner and my brother wants to put a hydraulic motor in his 74 Duster since he wants to never have to adjust the valves. However, my brother also wants to build a street performer out of the car, so we are going to use my big-valve head that has Ford 300 valves installed in it. The problem is the head came offof a 1972 198 motor, and therefore has the mechancical valve train rear bolt.

Looking at the diagram of the hydraulic cam passage in the hydraulic head leads me to believe that the whole purpose behind the modification to the rear bolt and the pocket for the rear bolt is to improve oil flow.

However, we all know that oil already flows into the rocker arm shaft on mechanical lifter motors because that is how the rocker arms get their oil. Thus, there is provisions on the mechanical head for oil to go to the same place as on the hydraulic head. The only difference is the rearmost bolt and bolt pocket. So if I grind the rearmost bolt on a mechanical head to an hourglass shape where the bolt passes through the bottom of the rocker arm shaft, then flow should be improved. It won't be as much as a factory hydraulic head, but it should be enough to keep the hydraulic lifters happy. I think I will be giving this a try.

Charlie- I think what Rugtrucker meant was:

|