Nothing too excitin' Here,

Starting the Trans removal process:

Take pictures of the Linkages before you take them out - It will help during re-assembly.

Greg

| Slant Six Forum https://slantsix.org/forum/ |

|

| Slant 6 10" Performance Clutch Install 3-16-12 https://slantsix.org/forum/viewtopic.php?t=48219 |

Page 2 of 14 |

| Author: | Greg Ondayko [ Sun Mar 18, 2012 3:41 pm ] |

| Post subject: | Began Transmission Removal 3-18-12 |

Nothing too excitin' Here, Starting the Trans removal process:   Take pictures of the Linkages before you take them out - It will help during re-assembly.  Greg |

|

| Author: | wvenable [ Sun Mar 18, 2012 4:54 pm ] |

| Post subject: | |

Gosh dern (Censored), recover those seats. Looks like a leisure suit my dad owned! |

|

| Author: | sandy in BC [ Sun Mar 18, 2012 5:09 pm ] |

| Post subject: | |

Disco Edition....... |

|

| Author: | Rug_Trucker [ Sun Mar 18, 2012 5:47 pm ] |

| Post subject: | |

In Mike Meyers Scottish brogue "IF IT ISN'T SCOTTISH? IT'S CRAP!!" |

|

| Author: | Dart270 [ Sun Mar 18, 2012 7:33 pm ] |

| Post subject: | |

Forgot about the friction insert. Bummer. It might be ok... Lou |

|

| Author: | Greg Ondayko [ Sun Mar 18, 2012 7:48 pm ] |

| Post subject: | Out With the Old 3-18-12 |

Quote: Gosh dern (Censored), recover those seats. Looks like a leisure suit my dad owned!

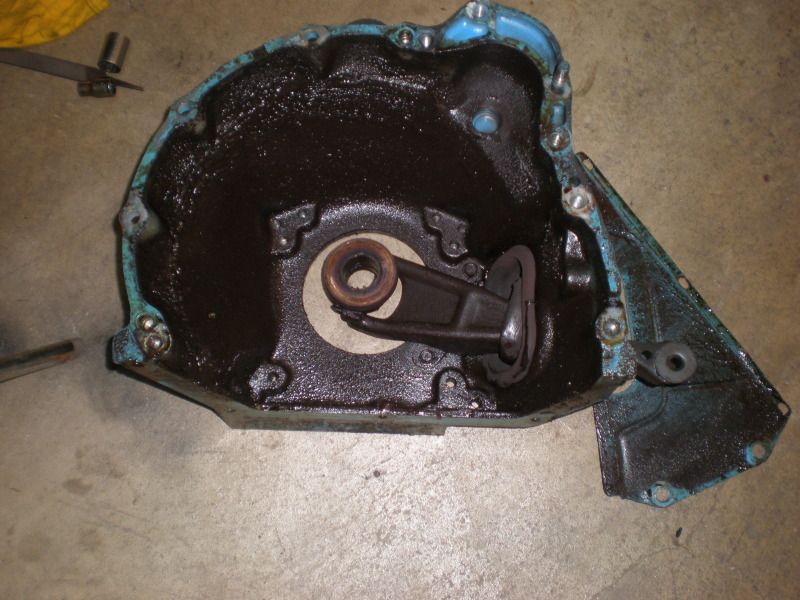

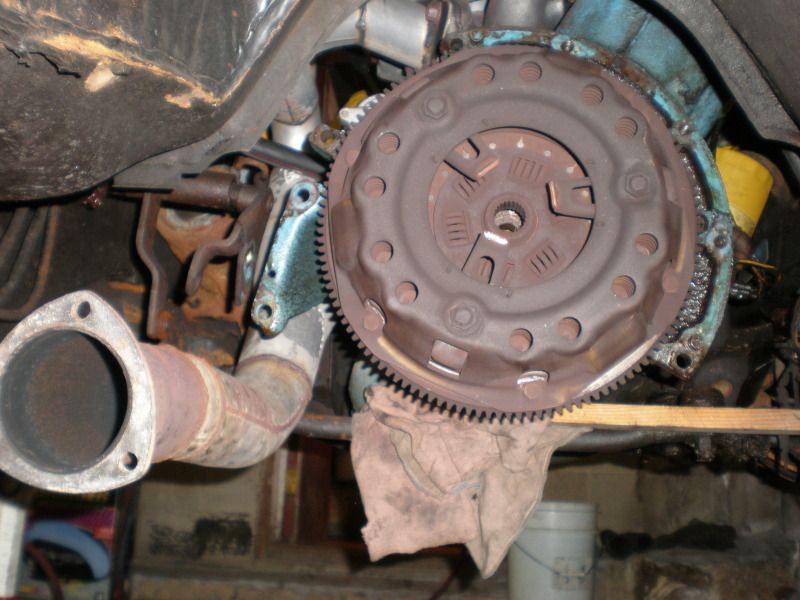

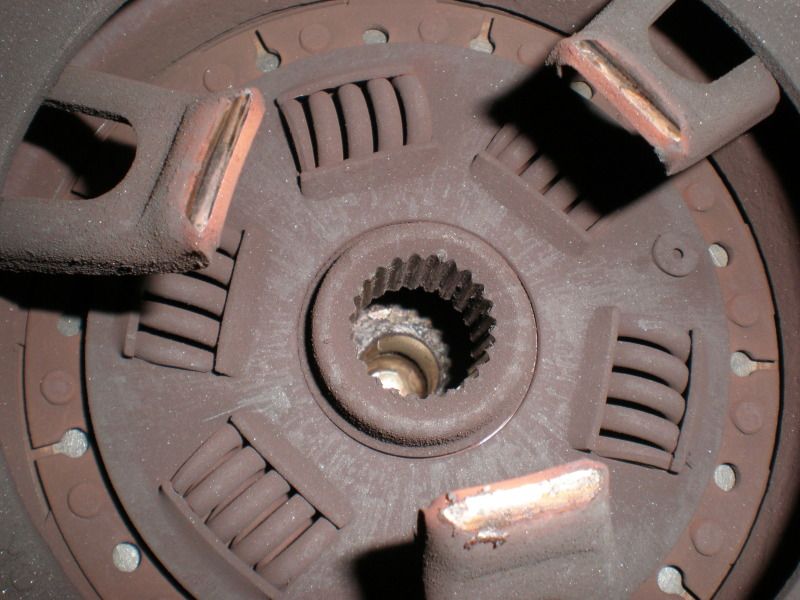

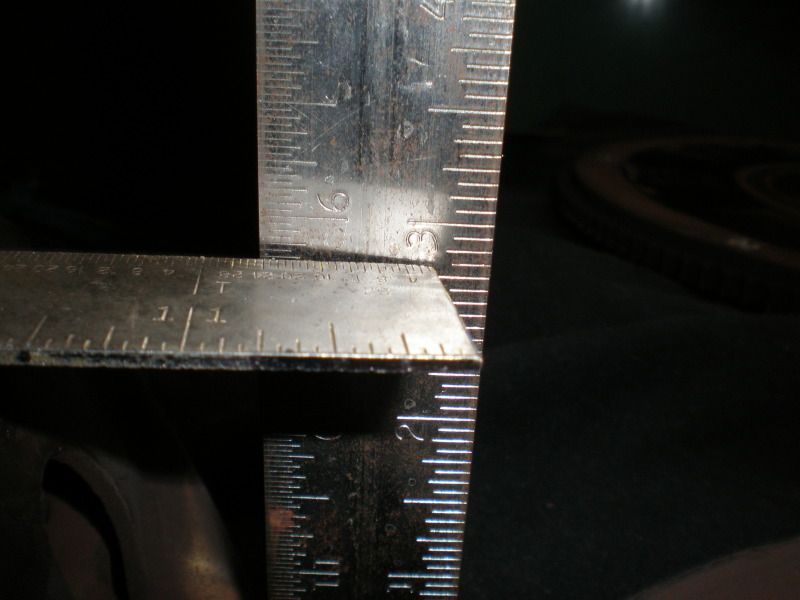

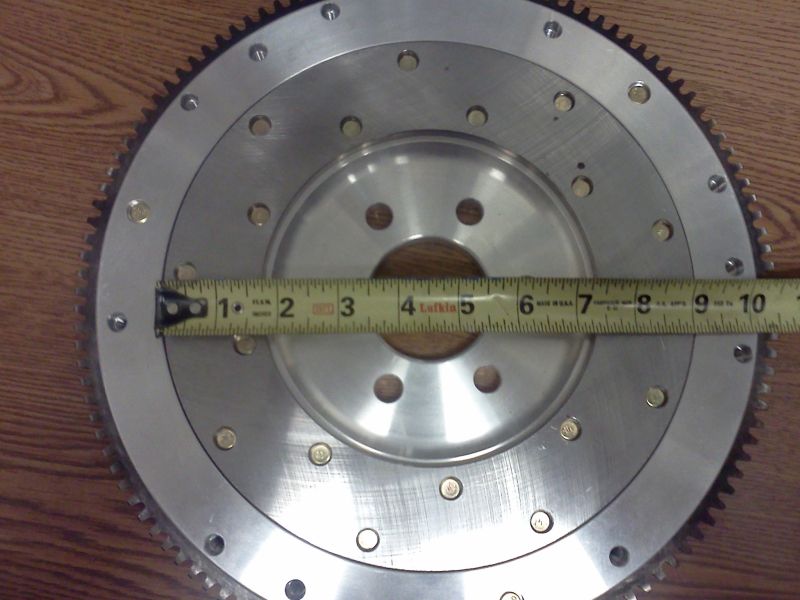

No Way wayne - I have Extras in my attic with the same fabric and I Bought out an Vintage auto upholstery warehouse - I have yards of that stuff.. Plaid On Brother!anyway back to business: I pulled the trans and old PP / Clutch / Flywheel out of the Duster.  Test fit the New disc on the actual trans in will be going on.. No issues.  Old Greasy Bell and other stuff will get a bath in the parts washer!   Here are some shots of the Old Flywheel, 10" custom Disc that I had used and Custom 10" Borg& beck Press. Plate. The Old Disc and Press. Plate were made by a local clutch Rebulder - He has since Retired and Closed Shop  This B& B Press Plate Has 12 Springs and I believe 2400# Holding force.. Good for a daily driver but it is the exploding Cast Iron Stuff    The Clutch Was a stock Borg & Beck 10" with 9 kevlar Buttons on it - Those buttons used to be 1/8" tall when It was new.       Pressure Plate Finger Height Comparison. Pay attention Here! This Is important for Making your Clutch Fork Pivot Shims. Stock PP:   This Measurement Looks to Be Right Around 2 3/4"  New McLeod PP Finger Height:  This Measurement Appears To be 2 5/8"  I will use this measurement to setup the the new Clutch Fork Distance - Based on my own other project with the McLeod parts, and others who have used these parts before 2006 You might have to shim the Clutch fork 1/4" to 1/2" Closer to the Engine to get correct Pedal travel & clutch rod geometry. Greg |

|

| Author: | vynn3 [ Mon Mar 19, 2012 9:54 am ] |

| Post subject: | |

For those of us considering a 4-spd swap but who know next to NOTHING about clutches and such (unless I'm the only one here...), Best. Thread. Ever. THANKS, GREG!!!!!!!! This should definitely be a sticky... |

|

| Author: | Greg Ondayko [ Thu Mar 22, 2012 3:29 pm ] |

| Post subject: | 3-22-12 Flywheel Issues/ Concerns |

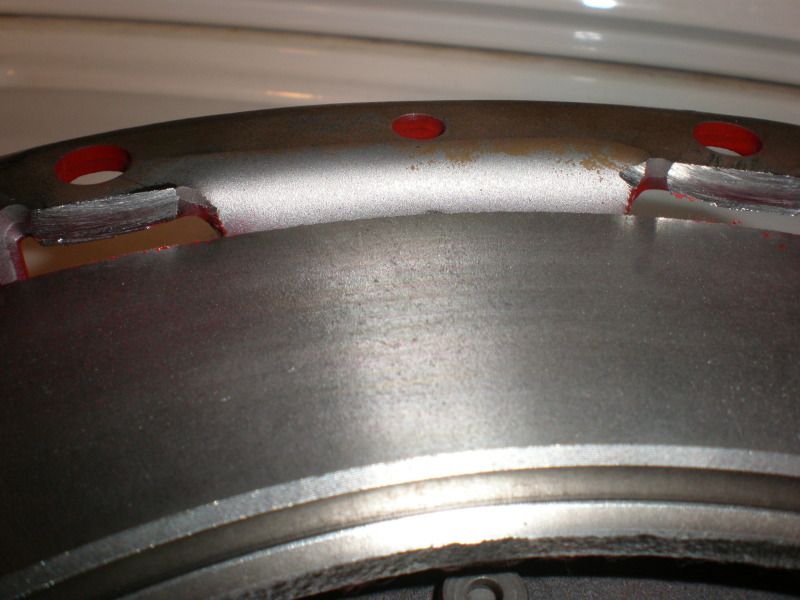

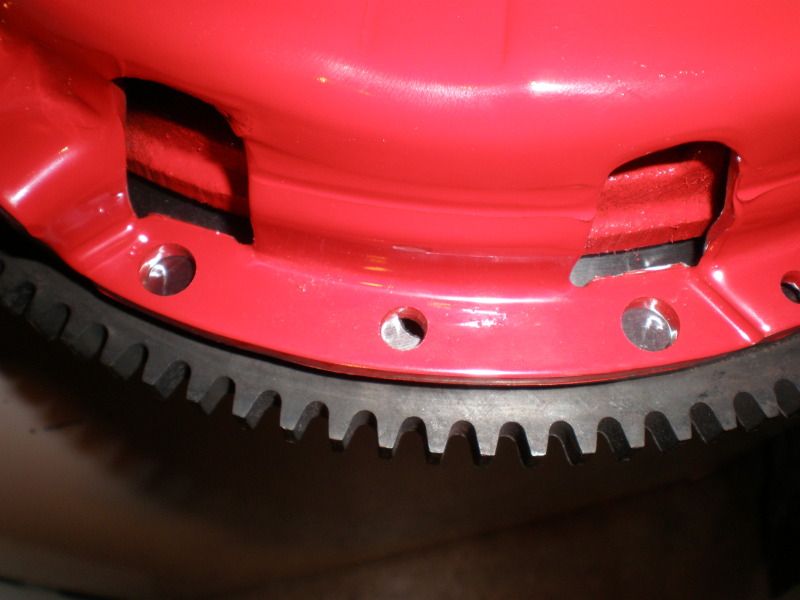

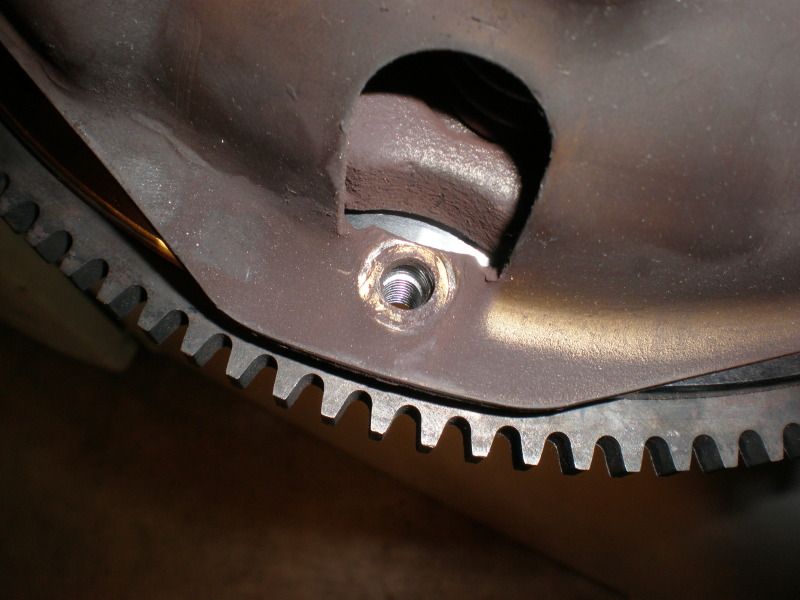

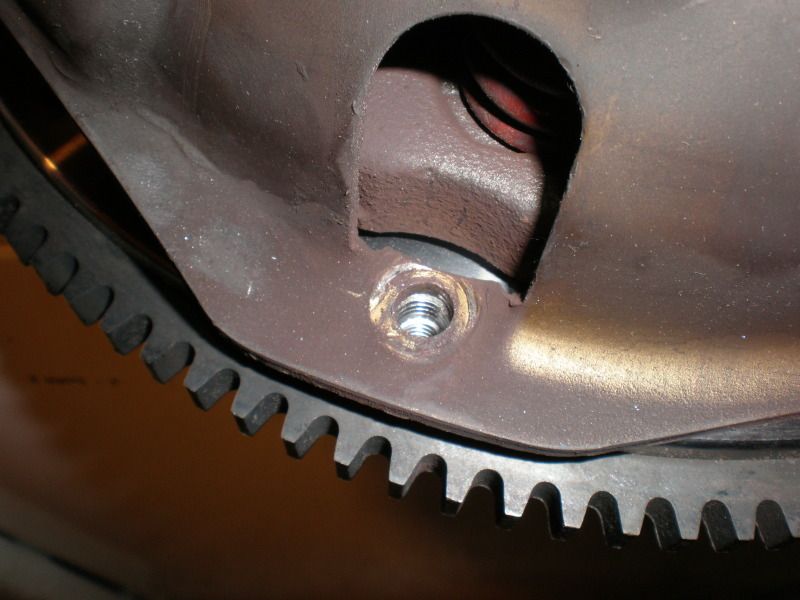

Well - A Moderator has Made this a Sticky! Thanks Mods! I have been pretty busy with work & other things so it's been a few days since my last update.. I have been piecing together the parts for this install and I noticed something of concern. I am trying to get an expert answer on this before I forge ahead with the project. I had particiaped in theWilcap AL flywheel Group Buy back in 2008. This is a super nice flywheel (i will do a weight comparison soon) that (if you read the old post) I was adamant about the Flywheel that I ordered having the Ford 10" pressure plate mounting holes drilled onto it. Well they are drilled on The Wilcap Flywheel and the PP i got last week from Summit/McLeod Fits fine on the Flywheel. My concern is the Steel Friction insert:  As you can see the insert is only 9" in diamater and the Clutch I want to use with this package is 10" and the PP is also 10".  With the Steel friction insert being only 9"..........1/2" of the clutch disc and pressure plate will overhang this steel insert.. I am not sure i that's a good thing.  I am waiting to hear back from wilcap to see if the Steel insert can be replaced with a 10" piece. I have not heard yet. The other option will be to by the Steel SFI certified McLeod Flywheel Part# 464001 Since I had the Wilcap Piece in storage in my shop I wanted to use it - The Mcleod Piece will be some more ca$h that I would like to hang onto if possible. I have one of the McLeod Dual Pattern Flywheels in the Dart - no problems - I just wanted to use the AL flywheel on this project. We shall see. If you have any thoughts on this chime in. Greg |

|

| Author: | Joshie225 [ Thu Mar 22, 2012 7:01 pm ] |

| Post subject: | |

The friction surface on the flywheel needs to match the disc. If it doesn't you're losing a lot of clutch area. |

|

| Author: | Dart270 [ Fri Mar 23, 2012 9:43 am ] |

| Post subject: | |

Let me know if Wilcap will redo the insert. I'd want mine done that way too. Thanks again for great thread. Lou |

|

| Author: | Greg Ondayko [ Mon Mar 26, 2012 10:49 am ] |

| Post subject: | Wilcap 3-26-12 |

Quote: Let me know if Wilcap will redo the insert. I'd want mine done that way too. Thanks again for great thread.

I spoke with the Fine Folks@ Wilcap and The 10" insert on the Slant AL flywheel is a no-go - THe technical reason is that there would be no meat left in between the AL the Steel insert and the Ring Gear Rivets..Lou The AL flywheel will be a 9" to 9 1/2" only clutch piece - I suppose I could get a Nice 9" PP and make that combo work - But that will be on another project.. I ordered the McLeod 464001 Flywheel and Once that comes in I will continue with the Install. Greg |

|

| Author: | Greg Ondayko [ Mon Mar 26, 2012 8:26 pm ] |

| Post subject: | Cleaning / Shimming / Trimming 3-26-12 |

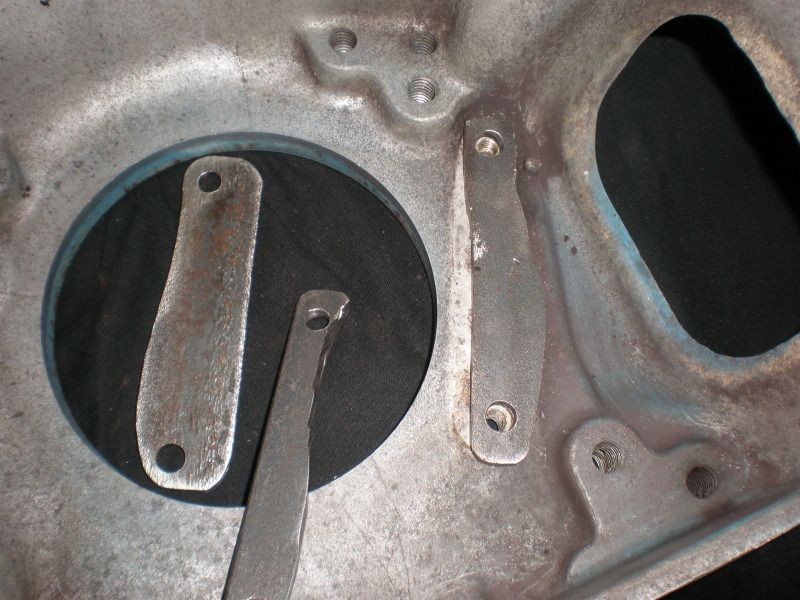

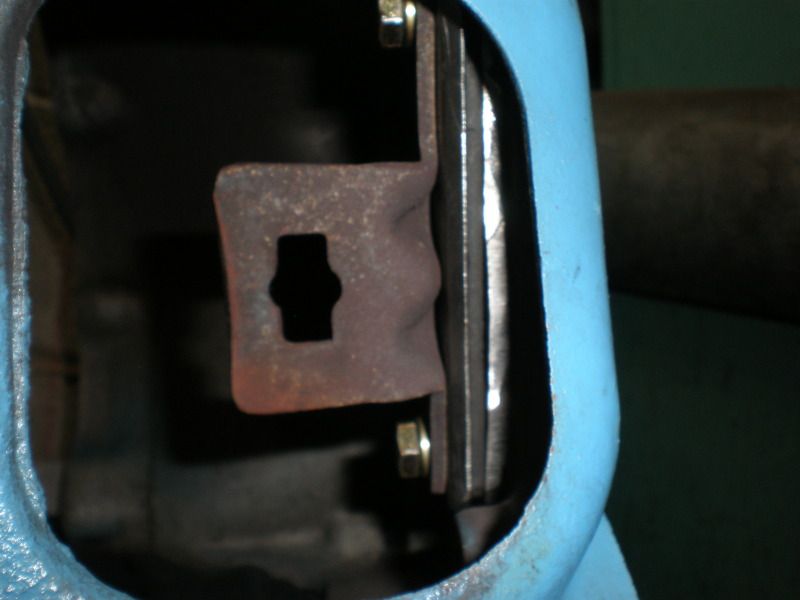

Here are the Next Step(s) in the Process: Before Re- assembly of the clutch / PP / Flywheel I like to Clean the Bell Housing inside and out before the Reinstall: Using The parts washer All the old greasy Gunk and clutch dust are removed from the stuff I am going to put back into the car:   The stuff is clean Now!   Even though I am not re-using the Old Flywheel on this project; I am cleaning it and Sending it to the machine shop for surfacing; I will stash it away and Possibly re-use it on another project Later  For This pressure Plate Install I will have to shim the Clutch Fork Pivot Closer to the Flywheel / Engine - If you are using a stock type Pressure Plate this step is NOT Needed.   I removed the Old Clutch Fork Pivot and Used it to layout some bits of Steel to make the spacer. I marked the holes and Got the general outline for the Spacers. Also the Stock Bolts That hold the Fork Pivot will be waaay to short so I will replace those too.  Here are some shots of the Spacers I made - I was using some left over angle Iron and Made the spacers - No they are Not Billet, nor are they pretty but they will do the job.    All 3 spacers are done; they measure about 1/2 Inch which should be just right for this setup - I can always unbolt the fork pivot and add or subtract the spacers to get it right.   Next are some shots will all the spacers and Clutch fork pivot installed and bolted down.. Notice the longer bolts needed for this.      All complete and A New Throwout bearing too.. I usually Toss In a New TO Bearing if I have the tranny out and I dont want to do the job again anytime soon.  Now Lets take a look at that 10" Ford/Mazda Pressure Plate from McLeod. I had some trouble with the clutch hitting / binding on the bolt hole material of the Pressure Plate Hat when I did this install on the dart back in 2006 - It is much easier to cut / grind these tabs before the install raher than after.  The Pen points to the Black line where I am going to make the cuts; This will happen on 6 of the mounting points.    Tools I used to do this hack:  Bits Removed - Not Much but enough to alleviate hassles later.  Photos of the PP after Cutting the six Little tabs off:   Pen Points to where the cuts were made:   Next: Test fitting the PP / Clutch / Flywheel / Clutch rod etc.. I have to Wait for the McLeod 464001 Flywheel to come in to do this. Greg |

|

| Author: | Rick Covalt [ Thu Mar 29, 2012 5:52 pm ] |

| Post subject: | Flywheel |

Quote: I ordered the McLeod 464001 Flywheel and Once that comes in I will continue with the Install.

Greg, It would sure be nice if McLeod could get the center registry right to start with. I know it is not a huge deal, but it should not need to be taken to a machine shop out of the box. It cost us $40 and 2 days of waiting to get ours done.Maybe this one will be correct? Let us know. great write up by the way!! Rick |

|

| Author: | Junior [ Sat Mar 31, 2012 2:29 pm ] |

| Post subject: | |

What makes the stock flywheel not a good choice for this mod? |

|

| Author: | Greg Ondayko [ Fri Apr 13, 2012 8:16 pm ] |

| Post subject: | Parts Update 4-13-12 |

@ Junior - Well I would not use the Stock Flywheel for 2 reasons - #1 It's made from Powdered metal - Like cast Iron I suppose.. In a performance situation Things could fly apart and this can hurt or seriously hurt someone Not to mention damage you car quite a bit.. I have been there - Not fun. #2 to use the Ford 10" PP the Bolt pattern for this on a slant Flywheel Has to be VERY close to the edge.. Near the ring Gear - The steel piece will do a better job with this small amount of material near the edge of the bolt holes.. and Not to mention you have to find a very competent machine shop to modify you stock PP to do this.. Could it be done .. yes I would not choose to do this. Update... I ordered part #McLeod 464001 This time I used a local guy in town that was cutting my old flywheel - He is a McLeod Dealer - So a few weeks go by and I get the flywheel in.. I ask him to check the Center register - 'cause If it needs machined out to 2.165" (i am installing in a '68 up application) He could do this before I picked up the part.. He verified that the part had indeed come in with the '68 Up register... Great. So I get home and notice the pP mounting patterns look funny... It came with 2Sets of Mopar Borg& Beck PP Mounting holes drilled on it. This certainly wont work.. Currently Waiting on a return to McLeod for a correction on this. I did not have this problem 6 years ago with the part in the Dart - It was right the first time with the dual PP mounting pattern. If you are interested in this flywheel maybe call McLeod Tech and Be sure to verify the 2 Patterns before they make yours. Pics: Here is the New McLeod Piece - Weighs 20# Notice the "double" stock PP mounts..  McLeod Piece Came in with the large Register:  Stock Flywheel Has been Cut a few Times - Weighs In @ ~17#  The Ford 10" PP does not line up anywhere on this McLeod Unit - It should - They screwed up:-(  Shots of the Stock PP lining up on 2 Sets of Holes. - Dumb      More to come when info is Available. Greg |

|

| Page 2 of 14 | All times are UTC-08:00 |

| Powered by phpBB® Forum Software © phpBB Limited https://www.phpbb.com/ |

|