Note to self:

Self, do NOT let duval67 work on any of MY engines - ever !:shock:

regards,Rod

hope it works out ok for you .

| Slant Six Forum https://slantsix.org/forum/ |

|

| Drilling rear cam bearing https://slantsix.org/forum/viewtopic.php?t=53194 |

Page 2 of 3 |

| Author: | CNC-Dude [ Sat Aug 31, 2013 1:38 pm ] |

| Post subject: | |

If you spun a cam bearing, chances are you not going to just be able to replace it with another one and everything will be fine. Its the same damaging process as spinning a rod or main brg, the cam bore is going to be out of spec and depending on how long you drove it this way, you may have to scrap the block, or pay tp have the bore resized and a custom OD cam bearing made. Since another block would be cheaper, thats what you can be up against. |

|

| Author: | SlantSteve [ Sat Aug 31, 2013 2:13 pm ] |

| Post subject: | |

The bearing that spun on me was run for thousands of miles before it moved.The machining In the bore of the cam tunnel left a lot to be desired,I was lucky, the interference fit was still there with a new cam bearing and it never gave another problem. The other fix if the tunnel is damaged is to machine it and fit a sleeve to restore the dimension back to stock and then fit a new cam bearing,I have needed to do this with other brand engines that I've built that have balance shafts in them,they use a similar bearing to a cam bearing. Of course the other option is to find another block if this one does have a problem.The motto to the story is you should measure and check the fit of the new bearing,don't just drive it in there and assume it will be fine. |

|

| Author: | RyGuyTooDry [ Sat Aug 31, 2013 2:55 pm ] |

| Post subject: | |

He just bought a good cam off of me, so he just needs to get the cam measured and get bearings accordingly. If the block is damaged Duval, you can take my extra '65 for $50 or something. -Ryan |

|

| Author: | duval67 [ Sat Aug 31, 2013 3:59 pm ] |

| Post subject: | |

Thanks man, much appreciated. Honestly did not measure anything. I put the bearings in, the rear spun when I was reaming them using a spare cam and stopped exactly where the old bearing spun too. Drilled the bearing in the location it stopped in and am honestly hoping for the best. The engine needs to run tomorrow to get me to Guelph for school and if it doesn't, it won't get fixed til thanksgiving, which would be the same result as if I took the time to measure and all that as I would not be done by tomorrow if doing that. So it's a bit of a gamble but I guess we'll just see. |

|

| Author: | walpolla [ Sat Aug 31, 2013 4:25 pm ] |

| Post subject: | Important note to me |

Note to self: Self, do NOT let duval67 work on any of MY engines - ever !:shock: regards,Rod hope it works out ok for you . |

|

| Author: | CNC-Dude [ Sat Aug 31, 2013 5:17 pm ] |

| Post subject: | Re: Important note to me |

Quote: hope it works out ok for you . |

|

| Author: | SlantSteve [ Sat Aug 31, 2013 5:36 pm ] |

| Post subject: | |

Hope....and maybe some loctite? I hope you drilled BOTH holes. If I did that I know what would happen,but Ive seen plenty of people get away with some rather "unusual" work practices ! Good luck with it......if all else fails it sounds like the perfect excuse to skip school! By the way,why are you reaming the bearings? If they go in nice and square they should be fine. |

|

| Author: | Reed [ Sat Aug 31, 2013 6:15 pm ] |

| Post subject: | |

Quote: I put the bearings in, the rear spun when I was reaming them using a spare cam and stopped exactly where the old bearing spun too. Drilled the bearing in the location it stopped in and am honestly hoping for the best.

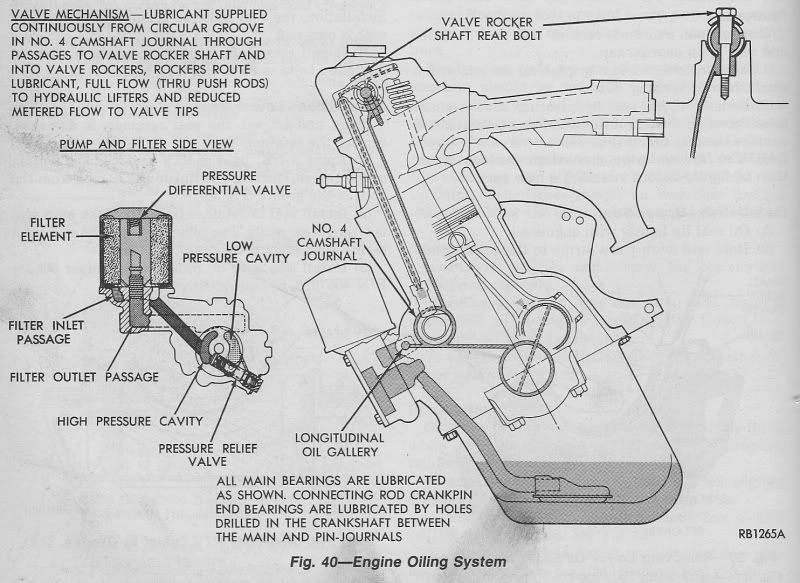

If this is the route you are taking, I hope you redrilled both holes. You need to have a hole from the top of the block down to the cam and a hole from the longitudinal oil gallery up to the cam. I sincerely hopes this work out for you. |

|

| Author: | duval67 [ Sat Aug 31, 2013 9:06 pm ] |

| Post subject: | |

Drilled both holes and no they probably didn't go in square because I didn't have the proper tool to install the bearings. Cam spins freely and no other bearings moved. Just making a daily driver exist again. I expect it to work. Appreciate your help guys and I understand how things are "supposed" to be done but you guys are working on your engines for different purposes than I am. Like I said, I expect it to work. I wouldn't work like this on someone else's engine either--doing it for my purposes. Sorry for getting a little defensive. Engine is back in, accessories to be bolted on in the morning and I'll be rolling down the road in the afternoon. |

|

| Author: | Reed [ Sat Aug 31, 2013 9:18 pm ] |

| Post subject: | |

Fingers crossed for you. Let us know how it goes for you. |

|

| Author: | duval67 [ Sat Aug 31, 2013 9:29 pm ] |

| Post subject: | |

Thanks, appreciate that. I'll let you know midday tomorrow. |

|

| Author: | ceej [ Sat Aug 31, 2013 9:40 pm ] |

| Post subject: | |

Stop! You have chips in the passages. No, you can't do this. The crap you popped loose is in the oil passage. Unless you want to prove us wrong, which I hope you do, stop and tear the engine down. Flush it out, and build it. I'm pulling for you, but this is absolutely the wrong way to go. 10¢ CJ |

|

| Author: | duval67 [ Sat Aug 31, 2013 9:49 pm ] |

| Post subject: | |

? I had the engine torn completely down when I drilled the bearings, maybe I didn't make that clear. I have blown and flushed the engine out entirely since swapping the bearings and drilling the rear one after it spun. |

|

| Author: | ceej [ Sat Aug 31, 2013 10:16 pm ] |

| Post subject: | |

Then you should have installed new bearings and measured everything. There are some things you just don't do, unless you only drive as far as you are willing to walk. Hope it works. Go for it, since you aren't going to listen. You aren't doing this right. Copy that, and then do whatever your going to do. I'm all for you proving us wrong. Tear it down, and do the work. Reliability only comes from properly built engines. Hack jobs live hack lives. 2¢ CJ |

|

| Author: | CNC-Dude [ Sat Aug 31, 2013 10:42 pm ] |

| Post subject: | |

Quote: unless you only drive as far as you are willing to walk. CJ

|

|

| Page 2 of 3 | All times are UTC-08:00 |

| Powered by phpBB® Forum Software © phpBB Limited https://www.phpbb.com/ |

|