Quote:

Quote:

$50! Try this: http://www.harborfreight.com/38-in-comp ... 68230.html

| Slant Six Forum https://slantsix.org/forum/ |

|

| PCV Air Oil Separator https://slantsix.org/forum/viewtopic.php?t=53666 |

Page 2 of 3 |

| Author: | pishta [ Tue Oct 29, 2013 8:35 am ] |

| Post subject: | |

The 2 90 ports (they are NOT turnable as I thought) on the top are the in/out port, just plumb the PCV hose to one side and the intake hose to the other. The 2 fittings included (clamped together) are solid plugs. No idea what they are for. The round bracket gets hose clamped to the body (little rubber stickers are for vibration?) and the flat bracket gets mounted to the firewall and then the screws bolt these together. The blue hose is just vacuum hose. When you get it, remove the top fittings and get some O-rings, as they use some sort of RTV gasket that MAY leak (might be fine out of the box) the 2 side fittings are doped and O ringed to the clear sight tube(can remove whithout taking hose off). The bottom is O ringed. Actually pretty good stuff for $20 shipped but its a little rough in the tapped holes. I had some tap flashing in the can, remove the bottom plug and look up in there and use a long screwdriver to knock flashing off tappings and clean out. Filter? I wouldnt use one as it would hinder the drain ability. The Filter should be on the breather anyway. Solids at velocity dont like to make turns so the oil goes straight to the bottom while the cleaner air happily makes the 90 and goes back into the intake. |

|

| Author: | Ssg Pohlman [ Tue Oct 29, 2013 1:13 pm ] |

| Post subject: | |

Quote: Quote: $50! Try this: http://www.harborfreight.com/38-in-comp ... 68230.html |

|

| Author: | Aggressive Ted [ Tue Oct 29, 2013 2:33 pm ] |

| Post subject: | |

Quote: Filter? I wouldnt use one as it would hinder the drain ability.

The Jeg's version has a very nice filter that keeps 99.9% of the oil out of the intake and engine. The cheaper units do not have this high flow filter. I take mine out once every 6 months and clean it with soap and water.The filter does in no way interfere the draining of oil. The oil drains out in a matter of seconds. |

|

| Author: | pishta [ Tue Oct 29, 2013 6:03 pm ] |

| Post subject: | |

So maybe some sort of K&N style filter sock on the inlet pipe inside? Perhaps that way it wouldnt get down in the oil. |

|

| Author: | kxracer728 [ Tue Oct 29, 2013 7:23 pm ] |

| Post subject: | |

Aggressive Ted, Could you use something like this with one of the universal catch cans on ebay? An inline oil/water separator on the outlet side of the catch can going to the carb. To catch any residual oil, debri before it gets to the carb...do you think this might restrict air flow to the carb? http://www.harborfreight.com/oilwater-s ... 68246.html |

|

| Author: | Aggressive Ted [ Tue Oct 29, 2013 7:33 pm ] |

| Post subject: | |

kxracer728, Maybe......but it would sure fill up fast..... You need a bigger container not smaller. The You-Tube video of the new Cadillac engine with one is huge in comparison to mine. It is about the same size as the Moroso air oil separators. |

|

| Author: | kxracer728 [ Tue Oct 29, 2013 8:50 pm ] |

| Post subject: | |

Quote: The You-Tube video of the new Cadillac engine with one is huge in comparison to mine.

Do you have a link? I did some searches can't seem to find the video...

|

|

| Author: | olafla [ Wed Oct 30, 2013 4:10 am ] |

| Post subject: | A catch tank design, and some notes on PCV valves |

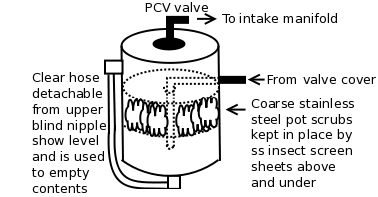

I made a thread last winter, asking about possible reasons for lots of foam on the dip stick, which I never have experienced before. I later found it to be a frozen PCV valve, causing the trapped water vapors to create foam in the engine oil. I am therefore making an oil/water vapor separating catch tank.

Unfortunately, the 904 in my Aspen broke down, so I haven't been able to test the catch tank yet. Besides, I am at a different location, so I can't even produce a photo. I will publish one later. Here is the source of inspiration for my version of the catch tank. If your engine is modified, you may need a different PCV valve, but which one? The PCV valve is a necessary addition to the engine to reduce emissions. It is vital that it is working correctly for another, more practical reason, and that is to remove vapors and gases in the crankcase which will create acids that break down the engine oil. The PCV valve is created for a spesific engine's flow of air through the crankcase, and the calibration is a combination of restrictor hole size, spring pressure, pintle size and design. The movement of the pintle is caused by vacuum and air flow, against spring pressure. Because a PCV valve is regarded as a vital part of the emission equipment, it's calibration is not made public, as it is not to be altered. Car manufacturers have taken the 'vacuum leak' caused by the PCV valve into consideration when they calibrated the carburetor or FI intake systems on a stock engine. An incorrect PCV valve may give unstable idle and low speed running problems, and also suck much oil. When the PCV valve is in low-flow position, it may be fully closed, or may have a small opening, depending on application. The moving pintle inside the valve can be a ball or a cone.

Situations that may cause the engine behave strange at idle:

An incorrect PCV valve may be the reason for some of the problems with carburetor adjustment on a modified engine, reported by some members. Using a PCV valve made for a High Performance engine with low vacuum at idle, may be a solution. This is a text copied from another forum, describing the calibration to a spesific engine. D. Positive Crankcase Ventilation (PCV) Valve 1. Test Procedure and Criteria a. Measure the flow of the PCV valve in standard cubic feet per minute (SCFM) vs. pressure differential across the valve over a range of operating pressures from 4-22 inches Hg., at standard atmospheric conditions (21.1 [deg]C (70 [deg]F) at 755mm (29.92 inches). b. A PCV valve shall flow within the vehicle manufacturer's specifications or shall meet the following criteria: Whenever the mean of the original equipment flow curve is below 1 SCFM, a maximum deviation of the mean replacement PCV valve shall not exceed 0.1 SCFM. Whenever the mean original equipment curve is equal to or greater than 1 SCFM, a maximum deviation of the mean of the replacement PCV valve shall not exceed 10%. The total flow tolerance of the replacement valve shall not exceed the original equipment variation from the mean, at any pressure differential. 2. Durability Procedure: The flow of any specific PCV valve must not deviate from the flow curve of the original equipment PCV valve by more than the total original allowable tolerance when each is similarly operated in the intended vehicle application over the service interval stated by the certifier. Olaf |

|

| Author: | Aggressive Ted [ Wed Oct 30, 2013 6:43 am ] |

| Post subject: | |

Quote: Do you have a link? I did some searches can't seem to find the video...

Sure, very easy to find...http://www.youtube.com/watch?v=Y9klkDCItEY Moroso TV: Moroso Air/Oil Separator / Catch Can test 2009 Cadillac CTS-V There are many of them I just happened to like this one since you could see it in action. |

|

| Author: | kxracer728 [ Wed Oct 30, 2013 9:57 am ] |

| Post subject: | |

Thanks...good example of how much oil is going back into the intake thru the PCV! I could tell on my truck awhile back when i disconnected the pcv line from the carb. I was surprised at how much oil residue was coming out of the hose and wondered how that was affecting carb, idle, tuning! |

|

| Author: | robertob [ Wed Oct 30, 2013 10:32 am ] |

| Post subject: | |

To add another data point to the PCV valve discussion: - some engines (LS2 GM truck from 2002 on) have no valve at all, but a tiny restrictor. Using a variable restrictor would enable you to tweak the flow until you get it to the exact right level. The downside would be a larger vacuum leak, but I bet you could adjust the carb to compensate. |

|

| Author: | Rug_Trucker [ Wed Oct 30, 2013 11:03 am ] |

| Post subject: | |

| Author: | pishta [ Wed Oct 30, 2013 11:51 am ] |

| Post subject: | |

Looks like a baby food jar! Hmm.......unscrew jar to drain..jb weld 2 stub outs into the cap or use bulkhead connectors, hose clamp cap to something...free! Efi can get away with murder as the ecu accounts for intake vacuum levels and can alter iac or even open and close pcv orifice. |

|

| Author: | Aggressive Ted [ Wed Oct 30, 2013 12:39 pm ] |

| Post subject: | |

Quote: Using a variable restrictor would enable you to tweak the flow until you get it to the exact right level. The downside would be a larger vacuum leak, but I bet you could adjust the carb to compensate.

You can do that with the filter media.

|

|

| Author: | Aggressive Ted [ Thu Oct 31, 2013 7:19 pm ] |

| Post subject: | |

Nice work Olaf! Thanks for sharing about the process of making your own and the filter media. Many of the eBay units do not have filters....which is a poor design. |

|

| Page 2 of 3 | All times are UTC-08:00 |

| Powered by phpBB® Forum Software © phpBB Limited https://www.phpbb.com/ |

|