Quote:

Very nice work, Thomas, snyggt jobbat!

Olaf

Thank you Olaf , Olaf

The Mad

| Slant Six Forum https://slantsix.org/forum/ |

|

| Slant 6 turbo project https://slantsix.org/forum/viewtopic.php?t=54579 |

Page 2 of 10 |

| Author: | Thomas S [ Fri Feb 14, 2014 2:41 pm ] |

| Post subject: | |

Quote: Very nice work, Thomas, snyggt jobbat!

Thank you Olaf , Olaf The Mad |

|

| Author: | Greg Ondayko [ Fri Feb 14, 2014 2:44 pm ] |

| Post subject: | |

Quote: Quote: Excellent work.

Nice to hear Greg, Its an incredible Na. slant Engine in your Ruster.Thanks for sharing. Greg High rewing + 6K ? hello Thomas, thank you. it is a 6200-6500 rpm through the traps in the 1/4 mile. Keep on slantin! Greg |

|

| Author: | Thomas S [ Sat Feb 15, 2014 6:32 am ] |

| Post subject: | |

|

|

| Author: | Thomas S [ Sat Feb 15, 2014 6:36 am ] |

| Post subject: | |

|

|

| Author: | olafla [ Wed Feb 19, 2014 4:31 pm ] |

| Post subject: | |

Thomas, you have obviously spent a lot of time thinking through the whole build process, and planned carefully what to do. Fantastic detailing, it looks very functional, but very pretty at the same time! Quote: The stock distributor is rebuild to a cam- hall sensor unit

Do you have some details on the distributor conversion for us, or maybe even som photos? Did you keep the mechanical advance mechanism, or did you only use the bare housing/shaft?Olaf |

|

| Author: | Thomas S [ Sat Feb 22, 2014 1:23 pm ] |

| Post subject: | |

|

|

| Author: | Thomas S [ Sun Feb 23, 2014 8:07 am ] |

| Post subject: | |

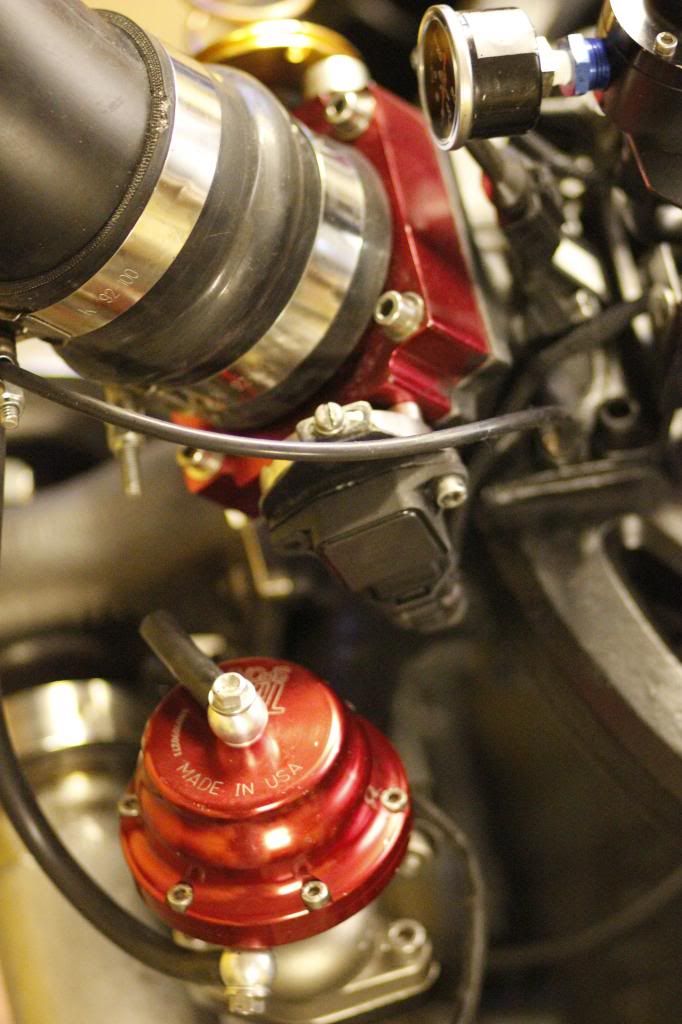

Her is a pic of the bosch fuel injector im using .( Bosch pt 1040 ) 1040 cc/min.(99 lbs / hr) You can also get them in 860 cc size. Note the extended nose. with this the fuel spray doesent start in a mine shaft... Quite good when you want less angle (about 30 degree) at the fuel injector bosses, to let fuel spray cone hit the valve pocket instead of the floor in the runner. |

|

| Author: | Thomas S [ Thu Feb 27, 2014 8:42 am ] |

| Post subject: | |

Now i have ordered the brain to my project. you can see the 3 tuning card including. One for long distance trips One for racing And one to pay the speeding fines.. This box take care of both fuel and ignition, fully secuential injection ,waste fire The same company that sell it, can also help me with the mapping.

|

|

| Author: | Thomas S [ Sun Mar 02, 2014 8:51 am ] |

| Post subject: | |

There are different type of hallsensor Constructions. I have found good information about cam- hall sensors at a Megasquirt page. To tell the computer if the engine are at the compression stroke or the exhaust stroke i use my old distributor And the hallsensor here is a 3 cable . One for power supply, one ground and one signal. The sensor have a magnet inside, and need something of normal iron-steel passing close to give signal There are other type of hallsensors, with no magnet inside , and they need a magnetic pointer, trigger passing close. Another type is commonly used in distributors . The vanes in the distributor rotates and block or unblock a magnet    My hallsensor converted stock distributor.  [/img] [/img] [/img] [/img]

|

|

| Author: | Greg Ondayko [ Sun Mar 02, 2014 9:31 am ] |

| Post subject: | |

Excellent Distributor Trick. Thanks for sharing these cam position sensor Mods. Greg |

|

| Author: | stop the beast [ Wed Mar 05, 2014 9:17 pm ] |

| Post subject: | |

very nice build. thanks for sharing. can't wait to see it in action |

|

| Author: | Thomas S [ Thu Mar 06, 2014 8:49 am ] |

| Post subject: | |

Thanks Tony, Yes same same here ...cant wait... Im in the process to prepare the car for the swap. I changed the exhaust to a 3 inch. It starts with a 3 inch pipe and after the firewall it split into two 2 1/2 inch . In front of the rear axle the two pipes going into a flowtech Terminator muffler. And continue with a U bend over the axle ( 3 inch) and finaly one small muffler. I try to minimize the sound inside the car, thats why i split into two pipes . Its nice muscle car sound now on the outside,.... but still little to loud. (with my stock Engine) I expect the turbo is also going to damp the sound? |

|

| Page 2 of 10 | All times are UTC-08:00 |

| Powered by phpBB® Forum Software © phpBB Limited https://www.phpbb.com/ |

|