Heck that was easier than I thought, they just came right off,

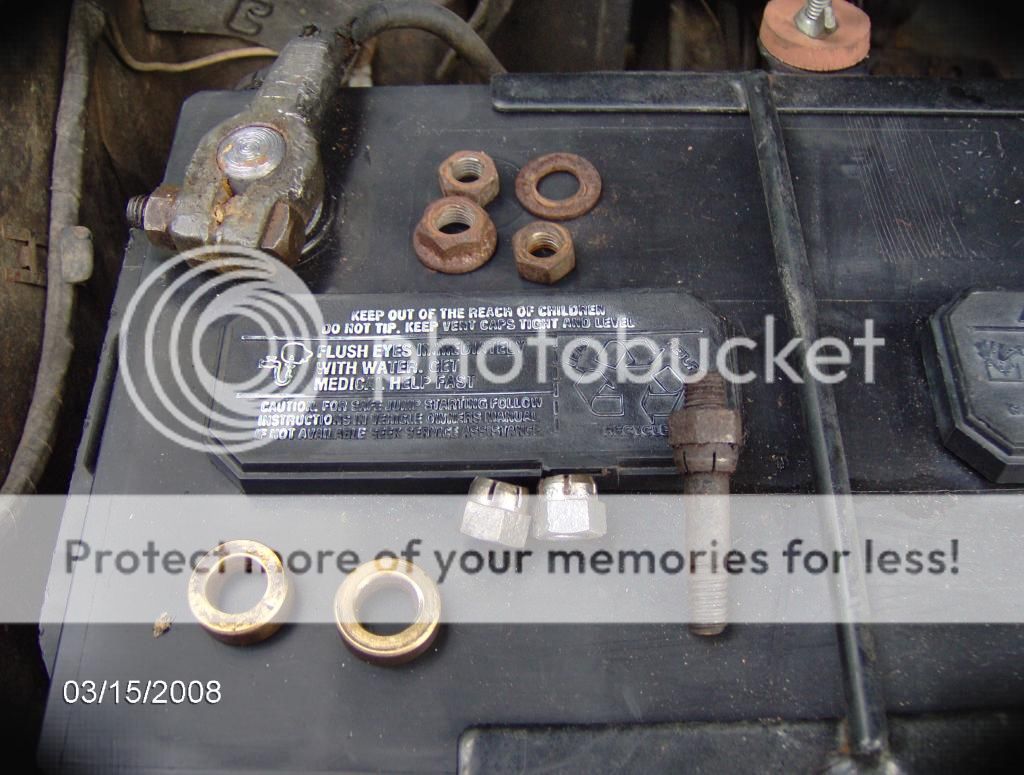

I usually end up with the entire stud coming out like pictured to the right. I have quite a few of these from junkyard vehicles ( that I pull cause you never know who might need one ) and most of the time even putting them in a vise, soaking them down, waiting ect they just will not budge.

I was lucky to have a set that was ready to go though, I will clean up the mounting surfaces a bit over the weekend with at least a wire wheel and put this new hardware on.

Thanks again for the replies.