Pretty much push & jiggle, some German rides have a CV flanges, and some

Subarus (older) have an axle stub the CV hub slips over w/a roll pin. Most

times they go easy enuff, but some days

the trans "squared up" on some.

| Slant Six Forum https://slantsix.org/forum/ |

|

| 350Z CD009 Six Speed Swap https://slantsix.org/forum/viewtopic.php?t=59484 |

Page 2 of 11 |

| Author: | Killer6 [ Fri Apr 29, 2016 8:32 am ] |

| Post subject: | |

That is correct, almost all FWD man. transaxles use no pilot bushing. This is because the input spans the length of the trans body and has a bearing on both ends,and is rigid enuff w/o supporting the tip of the input, which is generally pretty short in these apps anyway. Back to the subject tranny here, Me likey those ratios!!..... |

|

| Author: | bob fisher [ Fri May 06, 2016 5:14 am ] |

| Post subject: | one more question on fwd manual trans clutch jobs |

hi kill6- thanks for your answer on the non existency of pilot bearings on this type of trans. in the ancient history of rwd clutch jobs in slant 6s and old fords, i typically would put the trans in gear when putting it up in the bell housing ; in order to get the input shaft splines to slip into the clutch disc splines i would slightly turn the output shaft at the tail of the trans while keeping the trans straight and level. sometimes i would twist the trans a little and the whole assembly would slide right in and butt up against the bell. sometimes i would use pilot studs on the upper bell bolt holes to guide the trans. given the awkward close quarters of the fwd clutch job and trying to manuever the transaxle back on, im wondering what the procedural trick here is. do you just push and try to turn the trans to slip it through the clutch splines or put it in gear and try to turn the output shaft where the cv joints go in? as you can see i havent done an fwd transaxle r and r yet. thanks tons bob f |

|

| Author: | Killer6 [ Sun May 08, 2016 7:25 pm ] |

| Post subject: | |

Pretty much push & jiggle, some German rides have a CV flanges, and some Subarus (older) have an axle stub the CV hub slips over w/a roll pin. Most times they go easy enuff, but some days the trans "squared up" on some. |

|

| Author: | casedawg [ Thu May 12, 2016 2:41 pm ] |

| Post subject: | |

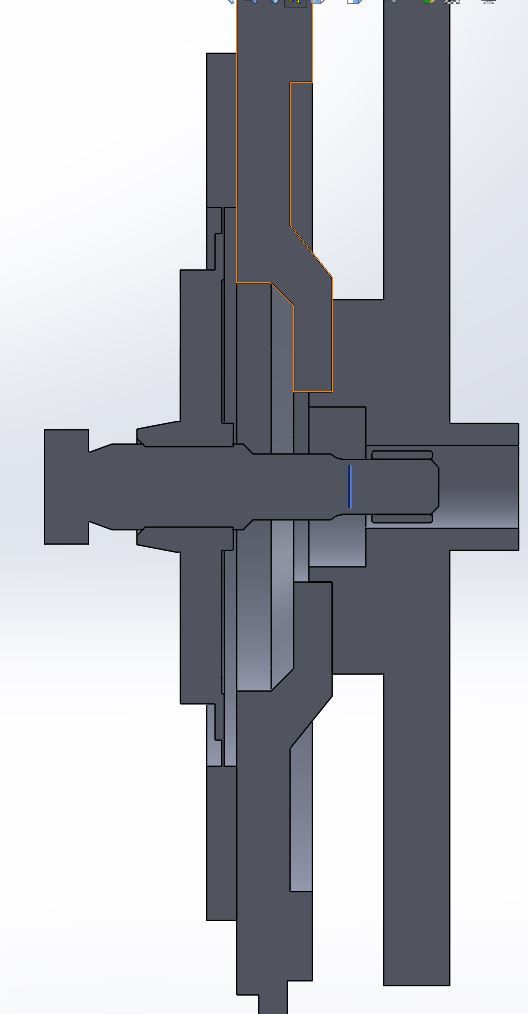

A quick update... I now have a 2006 CD009 transmission as well as a slant bellhousing and flywheel. I've reverse engineered the bolt patterns from both and I'm starting on the adapter plate design. I haven't explored the adapter between the slant bell and transmission option yet as that will require disassembling the transmission. I have a couple options for a plate between the engine and transmission. 1. Mill down the Nissan bellhousing about .5" and use a .375" thick adapter plate. That would create good clutch spline engagement.  This option would use a custom pilot bushing in the stock location. 2. Use a .5" flywheel spacer and move the starter accordingly with the adapter plate. This option would not require milling the transmission. This option would use a stock 350Z pilot bushing in an adapter bushing that goes in the larger bore on the crank. If you can think of another way I'm all ears. I have a feeling that the slant bell with an adapter to the transmission would be too long and we wouldn't be able to get enough spline engagement. |

|

| Author: | casedawg [ Thu May 12, 2016 9:20 pm ] |

| Post subject: | |

I checked the distance to the bearing retaining cover and I don't think an adapter between the trans and bell is the best option. The slant bell is deeper than the Nissan so unless a custom thicker flywheel was made with the ring gear in the same place for the starter, there isn't enough axial distance. There is a possibility that it could work if I took maybe .25" from both ends of the slant bellhousing. I think I'm going to proceed with cutting down the front of the Nissan bell about .5" This will require reaming the Nissan alignment dowel pin holes deeper prior to machining because they are only 13mm deep. Luckily, I double checked my machine Z travels tonight and the Nissan bell will just fit with a tool holder at ~19.125" tall. I still need to figure out what starter to use as I'll need one without a nose. |

|

| Author: | Joshie225 [ Fri May 13, 2016 7:55 am ] |

| Post subject: | |

My personal preference would be to make a flywheel spacer and leave the transmission case alone. Custom parts which wear out, and maybe the trans never breaks or wears out, are a turn off. The mini starter without a bearing in the nose can have it's nose removed. |

|

| Author: | casedawg [ Fri May 13, 2016 10:57 pm ] |

| Post subject: | |

What if you added a .5" thick friction surface with the pressure plate bolt pattern on the face of the flywheel that bolted on like the Fidanza flywheels? It would be heavy, but no need to mess with relocating the starter or machining the transmission. |

|

| Author: | Joshie225 [ Sat May 14, 2016 3:14 pm ] |

| Post subject: | |

A thick flywheel, especially an AL one to reduce the total mass, with a bolt-on friction surface appeals to me. Wilcap could easily make a plain aluminum flywheel to which you could add a steel plate. Or you could make the whole thing. |

|

| Author: | casedawg [ Sat May 14, 2016 5:44 pm ] |

| Post subject: | |

I'm kinda liking the custom flywheel option. It would allow: 1. No modification to the transmission bellhousing. 2. No modification to the starter location. 3. Possible usage of a Nissan clutch kit with the Nissan disk, pressure plate, throwout bearing, and pilot bushing. The thicker flywheel could be made to accept the 11" bolt pattern of the Nissan pressure plate in the thicker section. 4. The use of off the shelf 10" Fidanza friction surface in the $50-60 each range. A very rough mass estimate is in probably in the 12-14lb range for 6061-T6. There could probably be a light weight version as well. While I am at it, I may as well design a stock geometry version that can use the 10" friction surface for the Ford PP bolt pattern. I wish I had the info for where the clutch disk sits on the Nissan splines. I could make the transmission to pressure plate relationship the same as stock so the slave cylinder and clutch fork operate the same. Josh, Do you know what cars I can find the mini starter in? |

|

| Author: | DusterIdiot [ Sat May 14, 2016 10:56 pm ] |

| Post subject: | That's... |

Quote: Do you know what cars I can find the mini starter in?

Standard Denso for mopar that works with that standard ring gear is found in the 1990's trucks/vans with magnum engines...typically asking for one from a 1992 Dodge Truck with a 5.2 Magnum will get the standard nosed starter.... You might want to prod Dan, as I could swear that somewhere in the early 2000's (2003?), that Dodge had some trucks equipped with noseless denso starters.....if not they are easy to disassemble and use and angle grinder on the nose cone.Typical junkyard prices are $25-50 each...make sure to have them test it in front of you ...a few yards locally have sold me starters that...needed to have some reconditioning to make them turn over and not "click" and stick.... |

|

| Author: | Dart270 [ Sun May 15, 2016 7:29 pm ] |

| Post subject: | |

Might be worth buying a cheap/used clutch disc to see about spline engagement. This is what I did when I set up the T5 in my car. Lou |

|

| Author: | casedawg [ Sun May 15, 2016 9:11 pm ] |

| Post subject: | |

I did buy a clutch kit to take measurements from then returned it to the parts store. I just don't know where on the splines it actually sits when on the nissan engine. I really just want the clutch fork to work like stock and not have to mess with moving the pivot ball. |

|

| Author: | Dart270 [ Mon May 16, 2016 8:35 am ] |

| Post subject: | |

I went with a McLeod hydro TOB (concentric with input shaft) on my T5 swap. 50k+ miles and no problems, and no annoying mech linkage to mess with. Lou |

|

| Author: | the_engineers [ Mon May 30, 2016 7:24 pm ] |

| Post subject: | |

I just swapped the clutch/flywheel in my 2004 G35 6-speed. It's the same as a 350Z. Does anyone need the old parts? Cover the shipping and it's yours. |

|

| Author: | casedawg [ Tue May 31, 2016 5:38 pm ] |

| Post subject: | |

Would you be able to see how much it would cost to ship to 97119? |

|

| Page 2 of 11 | All times are UTC-08:00 |

| Powered by phpBB® Forum Software © phpBB Limited https://www.phpbb.com/ |

|