It is okay to let pcv draw fresh air for driveway testing. In that bbd manual on page 6 look for idle restrictors . There very small round brass inserts into idle channel just above idle mixture screws. Also on page 7 look at idle by-pass assist.

| Slant Six Forum https://slantsix.org/forum/ |

|

| Carter 2 BBD setup problems https://slantsix.org/forum/viewtopic.php?t=64895 |

Page 2 of 3 |

| Author: | matv91 [ Tue May 19, 2020 1:24 pm ] |

| Post subject: | Re: Carter 2 BBD setup problems |

Thread about metering rods https://www.slantsix.org/forum/viewtopi ... t=metering Adjust as needed just be safe about it. Allen head screw is to be adjusted to orignal setting. Lifter arm can also be raised. If adjustment makes big difference that means a different step- up spring is needed. |

|

| Author: | matv91 [ Tue May 19, 2020 1:55 pm ] |

| Post subject: | Re: Carter 2 BBD setup problems |

Idles wherever I tell it to, but I have not actually driven it yet. Tell us about your distributor and base timing, 6 too low try 12 to 16 degrees with pcv valve hooked up. |

|

| Author: | jamiefixit [ Tue May 19, 2020 2:34 pm ] |

| Post subject: | Re: Carter 2 BBD setup problems |

Quote: Idles wherever I tell it to, but I have not actually driven it yet. Tell us about your distributor and base timing, 6 too low try 12 to 16 degrees with pcv valve hooked up.

Aha. I see what you mean now. I've got it set to 5ish BTDC with the advance disconnected and the PCV hole blocked up until I put the rocker cover back on. But... I will try advancing it further as suggested. The A100 book says set it at 0 which seems like a bad idea to me, hence why I've advanced it a little already.I've seen a few different suggestions for how to set the idle screws. I have a vacuum gauge which I used on my old ford 302 motor, which i understand should give me optimum settings if I go for max vacuum. Otherwise I'll start at 2.5 turns in and then slowly work my way in until it starts to stumble and then back out a quarter turn, which is what I did so far? I've seen so many suggestions I'm not sure which to follow now. I was trying the old method of halfway between in stumble and out stumble but at 4.5 turns out it still wasn't stumbling.... I will also look at the metering thread. Thanks Mat, all of this is a big help. J. |

|

| Author: | jamiefixit [ Tue May 19, 2020 3:38 pm ] |

| Post subject: | Re: Carter 2 BBD setup problems |

Oh and yes it's an electronic upgrade distributor. https://www.ebay.co.uk/itm/253084160873 Basically replaces everything... |

|

| Author: | SlantSixDan [ Tue May 19, 2020 3:41 pm ] |

| Post subject: | Re: Carter 2 BBD setup problems |

Quote: Tell us about your distributor and base timing, 6 too low try 12 to 16 degrees with pcv valve hooked up.

No, 6° is right about where you want the base timing on an engine of that year and configuration. Those 12-16° settings are for (much) later engines. Original poster: timing gets set with the engine idling at about 700 to 750 rpm, the PCV valve installed and unblocked, and the vacuum hose pulled off the distributor and plugged. Quote: I'll start at 2.5 turns in and then slowly work my way in until it starts to stumble and then back out a quarter turn

See here for how to properly adjust the idle. Your vacuum gauge will be of good assistance.I fear you've made an error somwhere between "minor" and "causative" with your ignition system purchase; that's poor-quality Chinese knockoff parts and an ill-advised metal drive pinion. It is possible your spitback is being caused by ignition rather than carburetion problems. You'd be much better off either putting a Pertronix kit in the original dizzy or upgrading to HEI as described here. As to manifold gaskets: it is very much worth your while to get the good gaskets for the manifolds-to-head and intake-to-exhaust junctions. Do not extra-tighten the manifold fasteners; more is not better. Have you adjusted the tappet clearance…? |

|

| Author: | matv91 [ Tue May 19, 2020 7:28 pm ] |

| Post subject: | Re: Carter 2 BBD setup problems |

It is okay to let pcv draw fresh air for driveway testing. In that bbd manual on page 6 look for idle restrictors . There very small round brass inserts into idle channel just above idle mixture screws. Also on page 7 look at idle by-pass assist.

|

|

| Author: | matv91 [ Tue May 19, 2020 7:43 pm ] |

| Post subject: | Re: Carter 2 BBD setup problems |

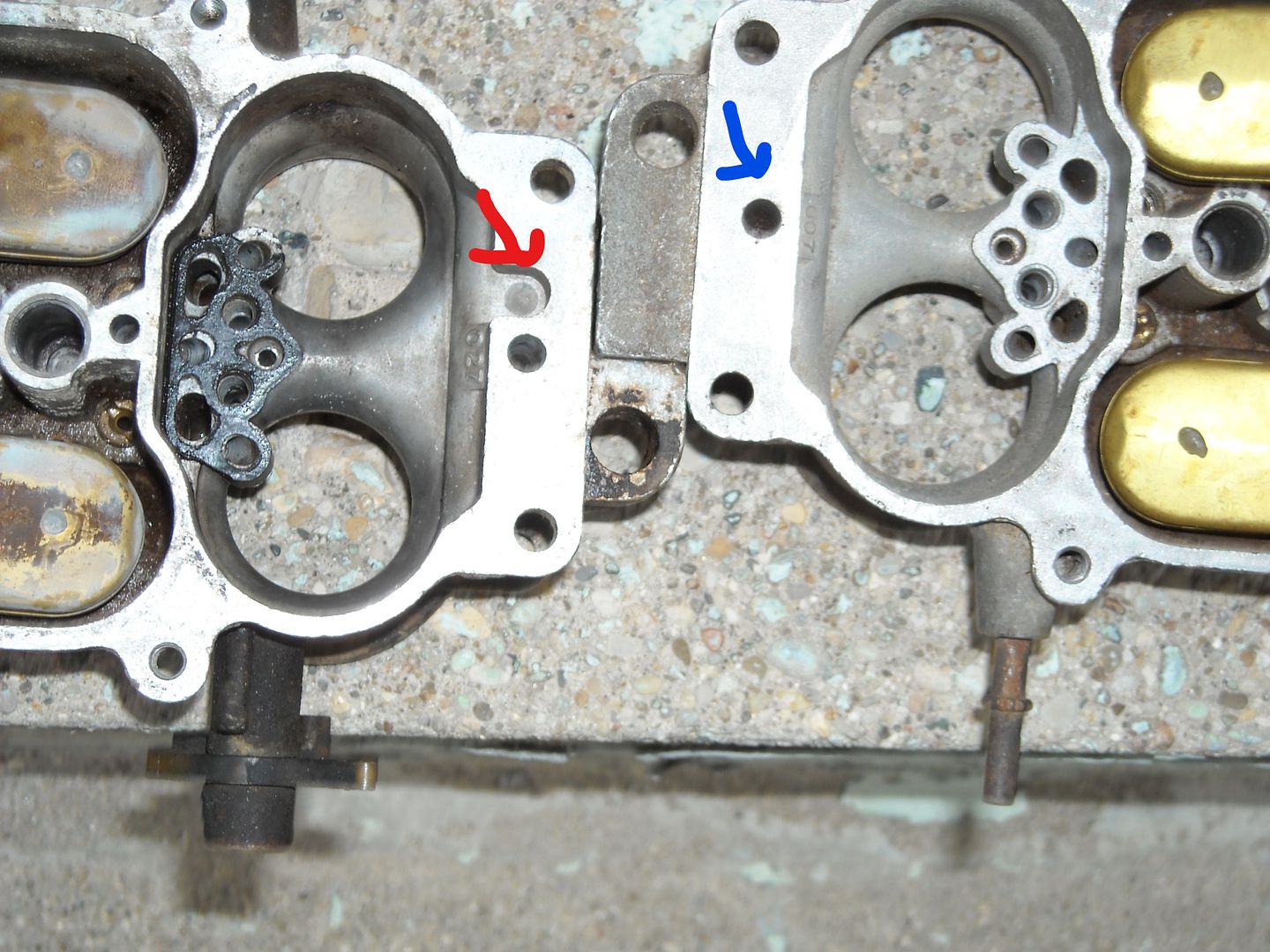

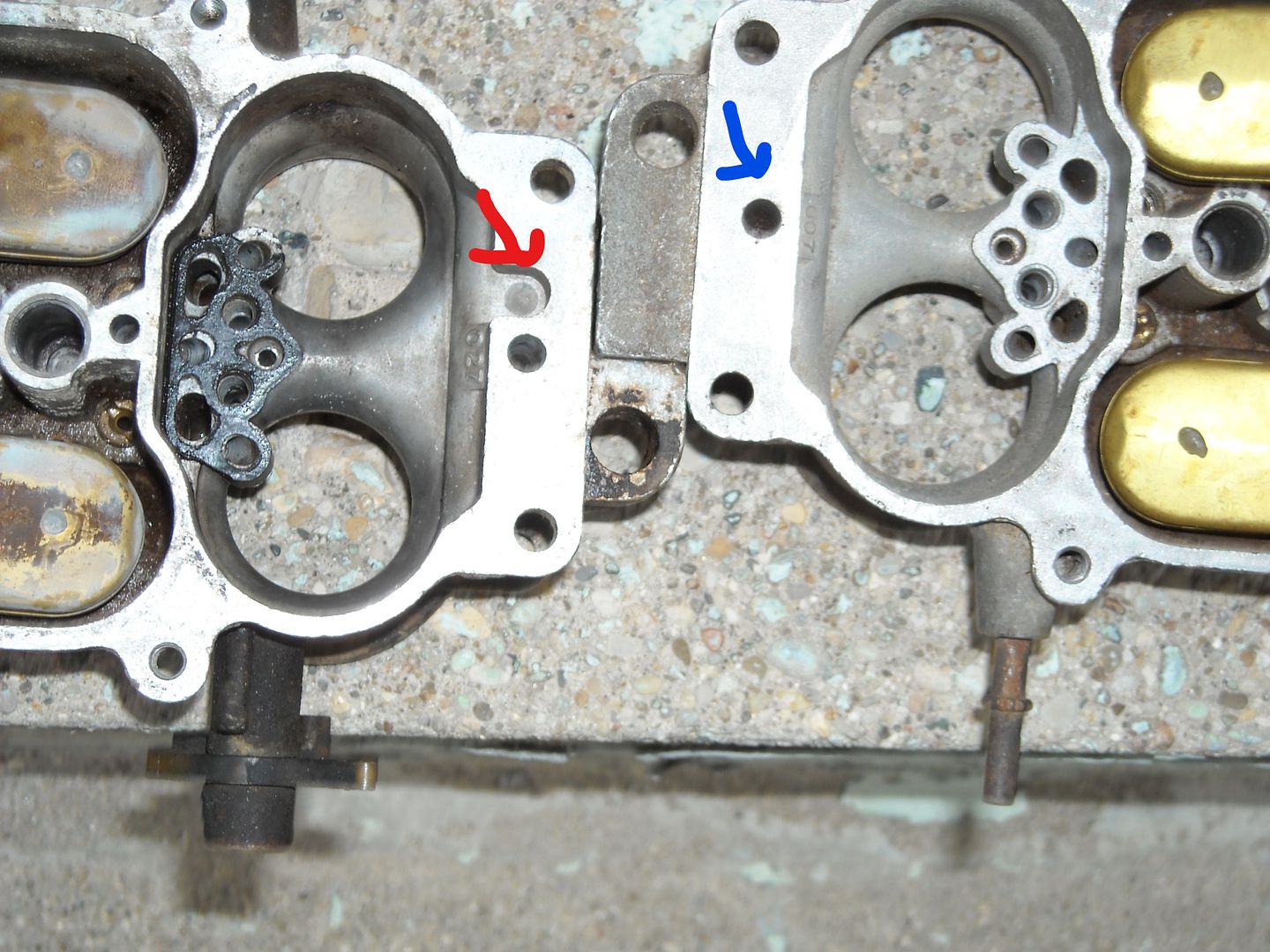

The red arrow points to idle by-pass assist hole on small venturi regular slant carb that hole is closed. On 318 V8 carbs with out holes in throttle plate it could be open. Engine might idle too fast |

|

| Author: | matv91 [ Tue May 19, 2020 8:54 pm ] |

| Post subject: | Re: Carter 2 BBD setup problems |

Next time the carb is apart can you get number from metering rod. Need mag glass. |

|

| Author: | jamiefixit [ Wed May 20, 2020 1:23 am ] |

| Post subject: | Re: Carter 2 BBD setup problems |

Quote: Quote: Tell us about your distributor and base timing, 6 too low try 12 to 16 degrees with pcv valve hooked up.

No, 6° is right about where you want the base timing on an engine of that year and configuration. Those 12-16° settings are for (much) later engines. Original poster: timing gets set with the engine idling at about 700 to 750 rpm, the PCV valve installed and unblocked, and the vacuum hose pulled off the distributor and plugged. Quote: I'll start at 2.5 turns in and then slowly work my way in until it starts to stumble and then back out a quarter turn

See here for how to properly adjust the idle. Your vacuum gauge will be of good assistance.I fear you've made an error somwhere between "minor" and "causative" with your ignition system purchase; that's poor-quality Chinese knockoff parts and an ill-advised metal drive pinion. It is possible your spitback is being caused by ignition rather than carburetion problems. You'd be much better off either putting a Pertronix kit in the original dizzy or upgrading to HEI as described here. As to manifold gaskets: it is very much worth your while to get the good gaskets for the manifolds-to-head and intake-to-exhaust junctions. Do not extra-tighten the manifold fasteners; more is not better. Have you adjusted the tappet clearance…? Had I seen the Pertronix kit originally I would have bought it. Used them in my Ford 302 to great effect. I'll pull the manifolds and just double check everything then reinstall with a 'good' gasket. I have checked and asjusted the tappets so they should be bang on factory now. Also I'll follow the thread for the base idle. I will also do the fuel line mod so that I'm not accidentally boiling the fuel before it hits the carb. Again, appreciate the thoughts. J. |

|

| Author: | jamiefixit [ Wed May 20, 2020 1:28 am ] |

| Post subject: | Re: Carter 2 BBD setup problems |

Quote: The red arrow points to idle by-pass assist hole on small venturi regular slant carb that hole is closed. On 318 V8 carbs with out holes in throttle plate it could be open. Engine might idle too fast

Aha useful stuff. I will pull it apart when i'm taking the manifold off and if it's open I'll close it. I will also look for the numbers on the metering rods... This is a big help thanks.J. |

|

| Author: | jamiefixit [ Wed May 20, 2020 9:29 am ] |

| Post subject: | Re: Carter 2 BBD setup problems |

OK, starting again today. I have pulled the carb apart and much like the diagram with the red arrow my carb has a dent where a hole might otherwise go. I have no idle restrictors and the needles are both 2226. I have ordered a pertronix set up from the UK distributor and also an amazing Remflex gasket set from the US. I've had to drill and tap the front bolt of the 3 that hold the manifolds together, the one with the spindly end because it snapped when I was taking it out a second time, weird... In the process being a genius I have managed to snap the tap off in the exhaust manifold. I've ordered a tap removal tool and with luck and a bit of heat I might be able to turn it back out again. Otherwise I need a plan B. Now we wait for the UPS man. |

|

| Author: | jamiefixit [ Tue Jun 09, 2020 2:28 pm ] |

| Post subject: | Re: Carter 2 BBD setup problems |

Hey people an update. I changed some stuff up and now it runs lovely. No backfire etc. I installed Rem??? gaskets on the manifolds, I added a Pertronix Ignitor II and flamethrower coil. I removed the ballast resistor, but it turns out I had two of them in series as there was another further back in the loom. This would have messed with the voltage, maybe a bit too much perhaps. I set the carb up as specified. It runs great but I still got water heading into the oil so I'm thinking maybe something is cracked somewhere. I'm waiting for some block sealer to see if that solves the problem... So wanted to say thanks for the suggestions. Somewhere the problems got ironed out. J. |

|

| Author: | SlantSixDan [ Tue Jun 09, 2020 4:29 pm ] |

| Post subject: | Re: Carter 2 BBD setup problems |

Oof, yeah, two ballast resistors would've made for very poor quality spark. Sounds like you've got things sorted. Water in oil: much eeking. Block sealer as anything other than a temporary hail-mary get-by deal to buy time before pulling and properly repairing a known crack: even more eeking. How much water is getting in the oil? Lesser amounts could just be condensate from a lot of short-run engine operation without reaching full operating temperature—what kind of thermostat is installed? Is the PCV system intact, properly configured, and working correctly? How much coolant (or water) are you having to add to the radiator? |

|

| Author: | jamiefixit [ Wed Jun 10, 2020 2:24 am ] |

| Post subject: | Re: Carter 2 BBD setup problems |

Quote: Oof, yeah, two ballast resistors would've made for very poor quality spark. Sounds like you've got things sorted. Water in oil: much eeking. Block sealer as anything other than a temporary hail-mary get-by deal to buy time before pulling and properly repairing a known crack: even more eeking. How much water is getting in the oil? Lesser amounts could just be condensate from a lot of short-run engine operation without reaching full operating temperature—what kind of thermostat is installed? Is the PCV system intact, properly configured, and working correctly? How much coolant (or water) are you having to add to the radiator?

A gentle stream of steam from the breather when it's running and maybe a pint leaks into the oil over a couple of weeks if I don't run it. So it's seeping through somewhere. Didn't see any obvious cracks when I took the head off and I looked! Because I could not obviously find where the head gasket had failed. I'm going to see what the block / head sealer does and work out what to do after that. I have a lower temp thermostat on it now, 72 deg C Pretty certain the pcv stuff is working now. I know the bottom end had just been done before I got it but it hadn't been run because they couldn't get it to go... The joy of buying a half finished project.

|

|

| Author: | SlantSixDan [ Wed Jun 10, 2020 1:50 pm ] |

| Post subject: | Re: Carter 2 BBD setup problems |

Quote: I have a lower temp thermostat on it now, 72 deg C

That's too cold—you want an 82°C thermostat. See here.

|

|

| Page 2 of 3 | All times are UTC-08:00 |

| Powered by phpBB® Forum Software © phpBB Limited https://www.phpbb.com/ |

|