I am starting to assemble another Slant Six engine and figured I would document the process as the engine goes together.

Seeing there is a lot of interest in "Eileen", the stroker SL6 engine build-up, I decided that this engine also needed a name. So based on the fact that this will be a light weight engine with long (thin) 198 con rods, Twiggy came to mind.

(will this engine be like the thin, light weigth super model of the 60's or will this Alm. Block SL6 break like a dry twig if I build to much power into it?)

Naming an engine, or a car for that matter is not something I usually do so this is a "first" for me. This will also be the first long connecting rod Aluminum Block SL6 I have built.

My hope is to show some assembly tips as move thru the build-up. Comments and questions are fine. I will do my best to focus in on SL6 specific details.

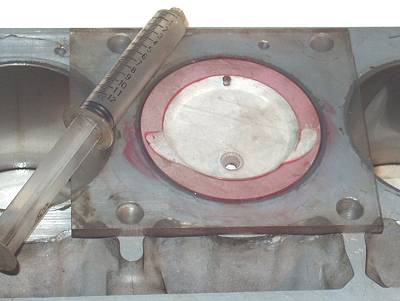

So here is where we start.... with the empty engine block.

For you sharp-eyed Slanters, what is different about this Alm. SL6 block??

DD