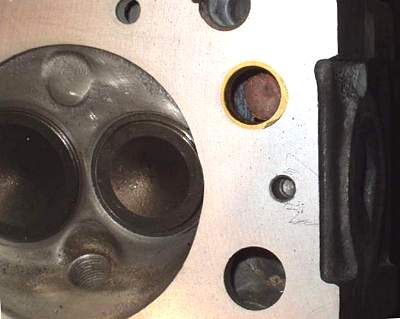

WOW, what a total waste. I dont know if the Ebay'er, or the UPS driver should be smacked the hardest.

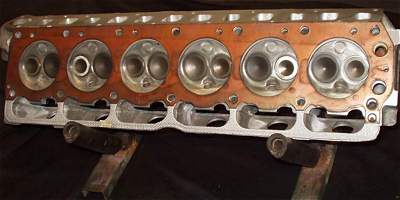

It looks like that gasket could be dulicated with a little effort. Have you seen the new MLS Phuzion Rings that just came out. They are a Gas Filled Flexable Ring made to take the place of the compression/fire ring. They even are loose and are just layed down in the gasket when you put them on. They cut the bore whole out in the MLS gasket to leave room for these rings that just lay on the block. No grooves or cutting of the block and head needed. I guess a MLS gasket with the bore cutout for these rings would tend to hold them in place a little bit. But if care was takin I dont see why they would not work with any gasket as long as it was matched to the thickness of the PHozion rings needs. You could take a regulor gasket, cut the fire rings out, put a copper shim backing on it like the one you pictured, and use the Phuzion rings.

Well, knowing you, there is a extra correct gasket laying there already and you dont need to worry with it. I plan on using these Phozion rings with double steel shims for a high boost Turbo /6 that will be getting built soon. The rings may not help or work for you at all I dont really know. But it might be worth looking into them if getting gaskets for that setup is become a problem. They do offer the rings in assorted bore sizes, and they are quite soft so working with the aluminum setup should not be a problem.

http://www.cometic.com/phuzion.aspx

Jess

|