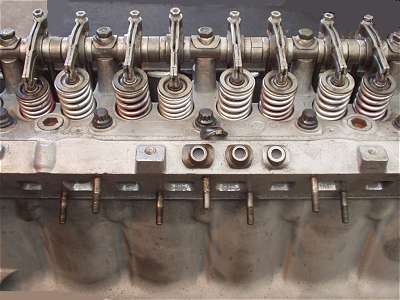

I have checked, measured, cross-checked, fussed and fiddled....

Time to install this head!

I run a light bead of High Temp. RTV along the outer "lifter rail" edge of the gasket, this ensures a leak-free seal there.

The main gasket surfaces get a light coat of spray-on "Copper Coat" sealer...

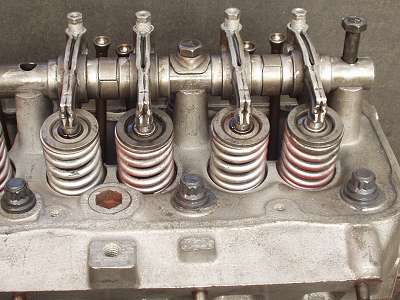

Oh... I almost forgot, get the lifters installed before you put the head on, it is a lot easier to do it with the head off!

(with later heads, you can not install the lifters with the head on)

DD