I'm not sure if I would call it "SL6 porn"... but all these "tricks & tips" should be good "food for thought".

We are getting close to done so be sure to ask questions or make comments... before I move onto the next project!

DD

| Slant Six Forum https://slantsix.org/forum/ |

|

| Twiggy - Long Rod Aluminum Block Engine Build-up https://slantsix.org/forum/viewtopic.php?t=23948 |

Page 15 of 25 |

| Author: | Doctor Dodge [ Mon Oct 22, 2007 9:33 pm ] |

| Post subject: | |

I'm not sure if I would call it "SL6 porn"... but all these "tricks & tips" should be good "food for thought". We are getting close to done so be sure to ask questions or make comments... before I move onto the next project! DD |

|

| Author: | Aggressive Ted [ Tue Oct 23, 2007 7:03 am ] |

| Post subject: | |

Doug, After break-in let's say you want to run 10-30 synthetic. Would you add the stiffer after market oil pump spring to increase the oil pressure? Sometimes with a thinner oil the pressure won't be as high as it is with dino oil once it warms up at idle. I usually stay around 40 lbs at idle and run at 46 lbs at cruise. With synthetic same pressure at cruise, but drops to 30 pounds at idle. Idle is at 550 rpm in gear. Example: Here is a listing on eBay http://cgi.ebay.com/ebaymotors/ws/eBayI ... 34500&rd=1 This is a High pressure Kit including spring - spring cap and instructions. Increases engine oil pressure over stock spring for high performance applications. Delivers up to 70 lb of oil pressure to keep your engine oiled and installs fast and easy in ALL /6 motors! Thanks for your thoughts. |

|

| Author: | 440_Magnum [ Tue Oct 23, 2007 8:41 am ] |

| Post subject: | |

Quote: Doug,

From what I've heard about the fragility of the slant-6 oil pump drive gear, I'd stay away from high pressure spings. 30 psi in gear at idle sounds plenty good to me, depending on where its measured. After break-in let's say you want to run 10-30 synthetic. Would you add the stiffer after market oil pump spring to increase the oil pressure? Sometimes with a thinner oil the pressure won't be as high as it is with dino oil once it warms up at idle. I usually stay around 40 lbs at idle and run at 46 lbs at cruise. With synthetic same pressure at cruise, but drops to 30 pounds at idle. Idle is at 550 rpm in gear. . Oil FLOW is more important than pressure, which is why I always avoid using a thicker oil to get a higher pressure reading. Thicker oil reduces the flow rate, even if it makes the pressure read higher. Some modifications that increase oil flow (like Doc's banana-slots on the rocker shaft) may actually cause a slightly lower oil pressure reading, but that's good because it means the oil is GETTING where it needs to go, not just sitting in the galleries and making a higher pressure reading on the gauge. |

|

| Author: | Doc [ Tue Oct 23, 2007 9:37 am ] |

| Post subject: | |

Improved oil flow to all the wear surfaces is the goal and it is the more difficult challenge. This is why I spend a lot of time in the oil passageways, opening-up restriction points, blending sharp corners, etc. More important are the "points of oil delivery" which are all the pressure "bleed-off" points. The question is always "how much oil is enough for the given moving part?" Do the rocker arms need more then a small "trickle" of oil? Are special, pressure fed "oilers" for the timing gears and the oil pump drive gear worth a 2-3 psi drop in hot idle oil pressure? Do you set the bearing clearances loose to reduce friction losses... and increase the overall oil flow requirements of the engine? It all becomes a "juggling act". We are lucky, the SL6 has high volume oil pumps available, two different sizes at that. The pump is exturnal and easy to adjust so I set the engine-up the way I think it needs to be, keep track of the oil flow requirements, match that with the proper size oil pump and then adjust the pressure to get the correct gauge reading. (10 psi for every 1000 RPMs) As for the high pressure spring, you don't need them. A washer or two stacked behind the stock spring is a great way to adjust the oil pressure level. For me, I put a special pressure adjustment "screw plunger" into the releif valve cap so I can quickly adjust the pressure right down to the psi. This type of cap is available for BB Mopar engines and fits the SL6. DD

|

|

| Author: | Aggressive Ted [ Tue Oct 23, 2007 9:49 am ] |

| Post subject: | |

The reason I asked is, Doug mentioned that the timing chain doesn't get that much oil on it when the engine is in stock form. I didn't get a chance to do his mod for more oil last fall when I rebuilt the motor. That is why I wanted to run synthetic, to be sure it stays lubed. I would like to prevent the chain wearing out any time soon. It runs too good. This is the first SL6 I have owned that didn't ping at the slightest load. In fact, I haven't gotten this engine to ping at all and I am at 60 degrees total. It can snap your head back, spin the tires with a 2.76 posi & P235 60 14's and still get good mileage. Thanks for your thoughts! |

|

| Author: | Doc [ Tue Oct 23, 2007 5:29 pm ] |

| Post subject: | |

If you started with a good quality gear & chain set, use good oil and keep it clean, your timing chain will last a long time. Did a "oil slinger" disc get installed in your build-up? The other tip is to keep your oil level up around the full mark but doing that creates extra oil windage that can reduce MPG. So... we can also think out of the box and plumb a small oil feed line right into the top of the timing chain cover. DD |

|

| Author: | Aggressive Ted [ Wed Oct 24, 2007 9:36 am ] |

| Post subject: | |

Doug, No slinger on mine, just the gear. Your right about the mileage going up. It can vary as much as 2 miles per gallon when I am at 4 quarts. 5 quarts kills the mileage, 22.5 mpg verses 24.5 mpg. That is another reason I was thinking of going to synthetic, maybe a 5-20 or 5-30 to reduce windage? What would you suggest now that it is built? That's why I was asking in the earlier post about the after market spring to boost the pressure back up. I am running 15-40 Valvoline diesel truck oil currently and it is 46 pounds cruise, 38-40 pounds hot idle depending on outside temperature. I like the idea of taping a hole in the chain cover. Now where can I pull the oil from, since the engine is in the car? These subtle things like windage, cam advance, valve lash, jetting, recurving, temperature, quality of spark, sure can make a huge difference in how this engine performs. |

|

| Author: | Doc [ Wed Oct 24, 2007 5:33 pm ] |

| Post subject: | |

Quote: These subtle things like windage, cam advance, valve lash, jetting, recurving, temperature, quality of spark, sure can make a huge difference in how this engine performs.

And that is why putting a good combination of parts together is only 1/2 of the battle.Getting everything tuned and "maximized" for driving conditions (and habits) is the other half of a good performing engine. DD |

|

| Author: | Doctor Dodge [ Wed Oct 24, 2007 8:35 pm ] |

| Post subject: | Picked-up some New Parts today... |

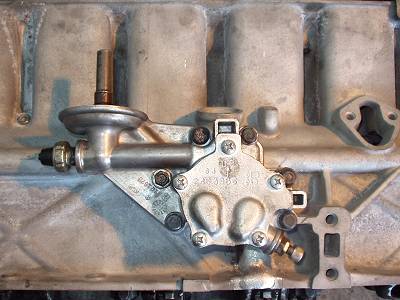

Purchased a new GMB made water pump today. These have the 8 blade impeller and bevelled separator plate.  I also "sprung" for some new bolts and went as far as getting a couple of stainless steel bolts... these are the two longer ones that go into the water jacket. The water pump was $32.00 and the bolts were another $5.00 DD

|

|

| Author: | Aggressive Ted [ Wed Oct 24, 2007 9:02 pm ] |

| Post subject: | Water pump |

This is pure ..... very nice! I used stainless as well, no more corrosion. Too bad you can't get that pump at NAPA. |

|

| Author: | SlantSixDan [ Wed Oct 24, 2007 9:03 pm ] |

| Post subject: | |

Interesting, never seen an 8-blade impeller or bevelled separator plate like that. Do you figure these are design improvements over the 6-blade impeller and flat plate? |

|

| Author: | AnotherSix [ Thu Oct 25, 2007 9:48 am ] |

| Post subject: | |

I have used GMB pumps in both my Chevy wagon and Grand National. They both worked fine and I never changed them again until going thru the whole engine, at which point they looked fine but were replaced anyway. The buick has a flow thru cast impeller and the gmb was just like stock, the chevy had the 8 blade stamped impeller, they are normally six. Myself, I really cannot say if 8 blades are better than six overall. I can see it being better at low rpm since there is more contact with the water, and worse at high rpm for the same reason. Those flow cooler disks do help with this style impeller, but if you don't need it there is no point in loading the pump more. I put a "Cardone select" pump on our slant, and it appears to be the same as the GMB pump in the pictures. I would not at this point use any of their rebuilt stuff, but when shopping for a water pump I wanted to be sure to get an new aluminum one. It has worked fine even in 110+ degree heat and traffic. My only concern is the separator plate eroding as the miles add up. |

|

| Author: | argentina-slantsixer [ Thu Oct 25, 2007 11:50 am ] |

| Post subject: | |

hey doug where did you get that water pump? I need... NEED one! |

|

| Author: | Rick Covalt [ Thu Oct 25, 2007 2:51 pm ] |

| Post subject: | What is GMB? |

Help me out, I'm a little dense around the edges. GMB |

|

| Author: | SlantSixDan [ Thu Oct 25, 2007 3:10 pm ] |

| Post subject: | |

Quote: Help me out, I'm a little dense around the edges. GMB

GMB, not to be confused with GWB.

|

|

| Page 15 of 25 | All times are UTC-08:00 |

| Powered by phpBB® Forum Software © phpBB Limited https://www.phpbb.com/ |

|