Problem :

This Truck was running badly, many previous

owners hacked, removed, replaced

components and wiring such that the

computer was not getting all the inputs

it needed to function. Therefore

the lean burn system "defaults"

to get you home timing. The result

high fuel consumption and poor performance.

So bad in fact that the truck

or the system had to go. It was a

lean burn w/o 02 feedback.

There are many ways to do the conversion

this is just one ----

Some may consider this overdone....I agree,,,

had time on my hands, and, I only like doing

things once!

I have visited this site many times and "taken"

away a lot of information. This was an opportunity

for me to "give back"to the forum. Many of you

pros out there know this is a simple conversion.

But, for some, it can be challenging.

For me it was an opportunity to fabricate a

solution and share it with others. Enjoy.

Step 1

I Read info from here (hei section, and FORUM)

regarding reasons to convert, technical advantages,

parts needed, and How To.

Step 2

Ordered "Shop Service Manual" from:

politpaul@yahoo.com

reasonable and professional, "no CD" "paper back original"

Note: READ YOUR MANUAL!

some electrical diagrams are posted

in the previous post on this subject which relates

to this modification! I will also modify a simple

wiring diagram when finished posting

Step 3

Consulted local Emissions people, and emissions

map on truck to determine if truck would meet

regulations with removal of "EFCS"

Important, a little effort here will save you a

lot of grief later, saving you money and repeat trips to

junk yard looking for those parts you discarded!!!

CONSULT YOUR OWN PARTICULAR STATE/COUNTY

Step 4

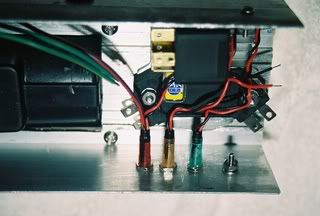

Ordered Parts

NAPA

coil napa echlin # IC24

relay napa echlin # AR274

hei module napa echlin # TP45

coil wire napa belden # 701050

coil connector napa echlin # ICC1

heat sink ac delco # 00212G4

LC01 ACD# 10474610

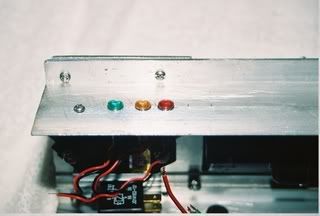

leds radio shack # see pic,,many to choose

from

Some Photo's of the Individual Parts

Ordered Carburetor from:

Carburetor Specialist

5715 N Commerce Ct.

Suite 200

Alpharetta,GA 30004-4178

(678)393-1501

My salesman was Greg

Their Part # NC- 108-2404 Carter BBD/DC

Note: These people are expensive but very

competent. They will get you the right carburetor

if you answer their questions.

Replaced carburetor on truck with NEW mechanical,

non-computer type BBD No pic of old carburetor

as it was sent to shop in exchange for

the new one. Installed the Carburetor and

used old mechanical electric heated choke to test.

Will probably replace with a mechanical cable type

when conversion is finished.

Step 5

Installed Carburetor - Test to make sure engine

runs correctly.

Ordered Distributor from:

Old Car Parts NW, Inc

1120 SW 16th Street #7

Renton,WA 98057-2639

(206)300-1083

Email ocpnwi@gmail.com

Replaced distributor on truck which was lean burn dual

pickup, non vacuum advance, with Mechanical

Electronic Vacuum Advance

part # 3874714 as suggested on these posts

Your manual may also have a P/N.

See other parts of forum for Distributor variations

and modifications.

Step 6

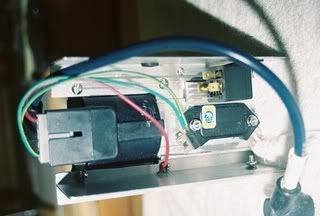

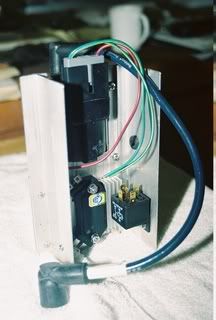

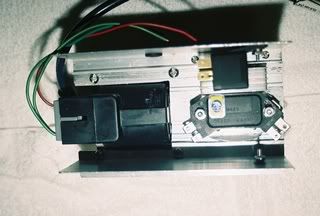

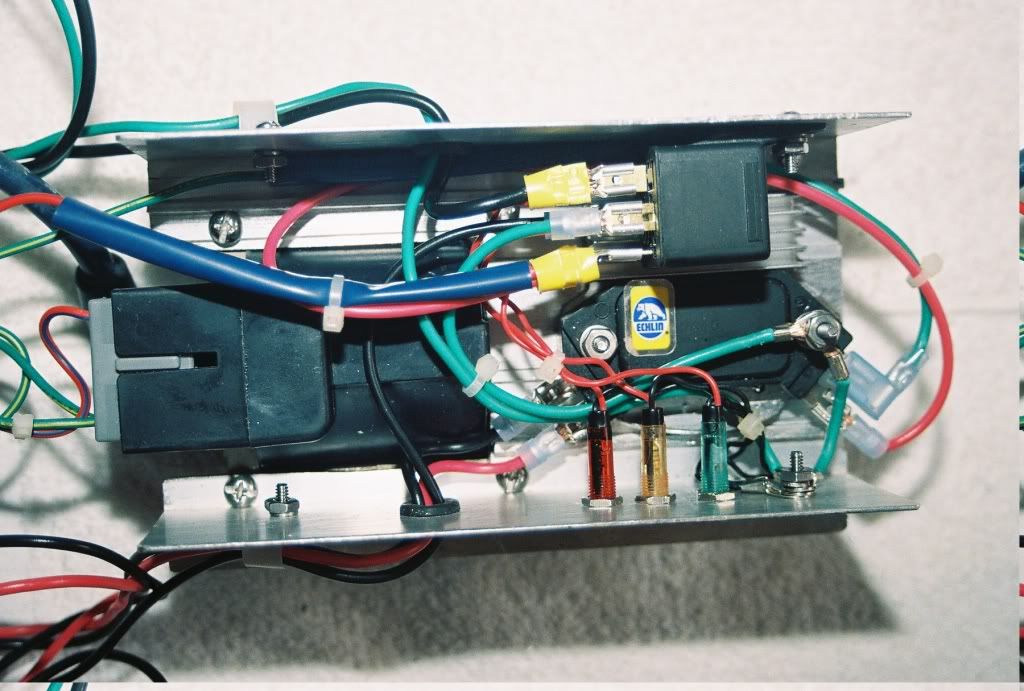

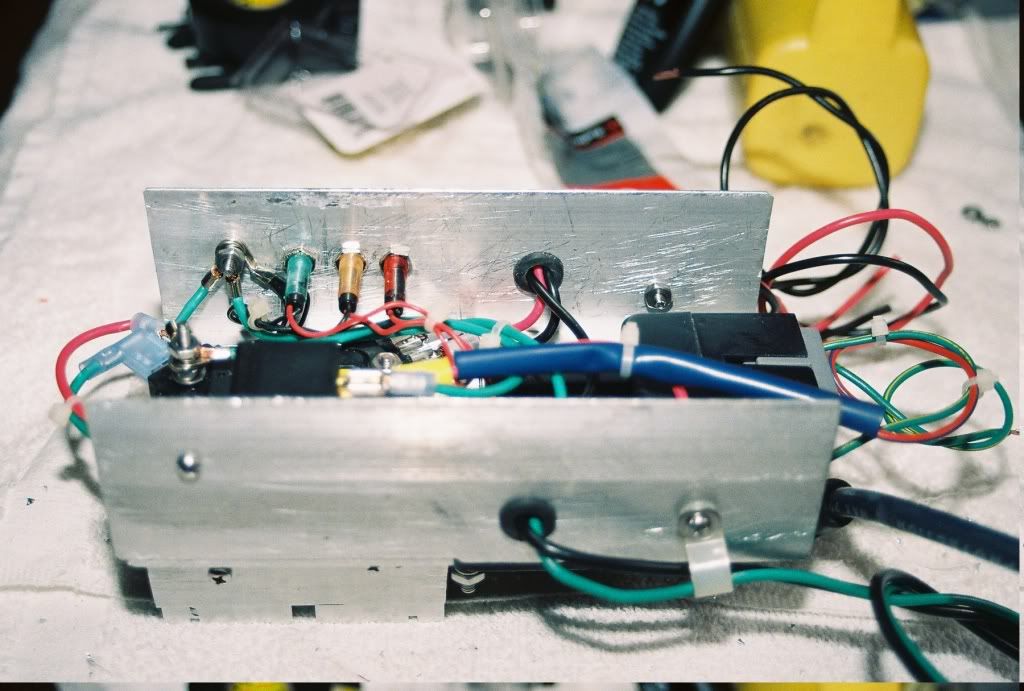

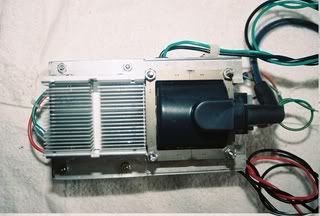

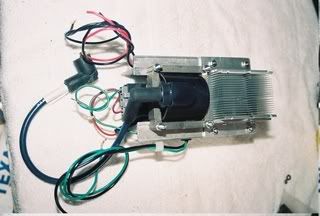

Fabricated Unit

Found window or door aluminumchannel

at junk yard.

Found heat sink at computer store scrap bin,

came out of desktop computer (would be

lower profile if you can find one

from a server)

Yep, went overboard with heat sink,

"YOU" do not need that much. (personal philosophy,

I OVERBUILD !)

(a little about ht transfer later)

Fabricated the above parts into the channel

Used all stainless steel machine fasteners

fastener sizes machine --6/32 8/32 10/32 10/24

(screws, flat & lock washers & nuts)

Used shrink wrap when splicing

Used insulated connectors and crimped wiring to them #12 #14 #16

Used quality automotive wiring ---#12 #14 #16 copper

Used rubber hole grommets

Used nylon wire holders

fused main power supply to unit , (20A) #12 copper wire

All grounding wires "non-insulated stainless connectors crimped"

Use hi quality automotive electrical tape and tie raps

Note: This is important, PUT 20A fuse assembly

as close to the battery as possible. If there's an electrical

fault in the system or between the battery and the

system the fuse will protect the module and wiring

to the module.

Note: When placing hei unit make sure you place on flat,flush surface

and use the dielectric grease. My hei (napa) had a couple

of plastic placement dowels that i filed off, which then allowed it

to lay flat and flush.

Because of an irregularity in the door/window channel i

selected, i used the GM AC DELCO heat sink so the hei

unit would sit flush to the channel. This is important.

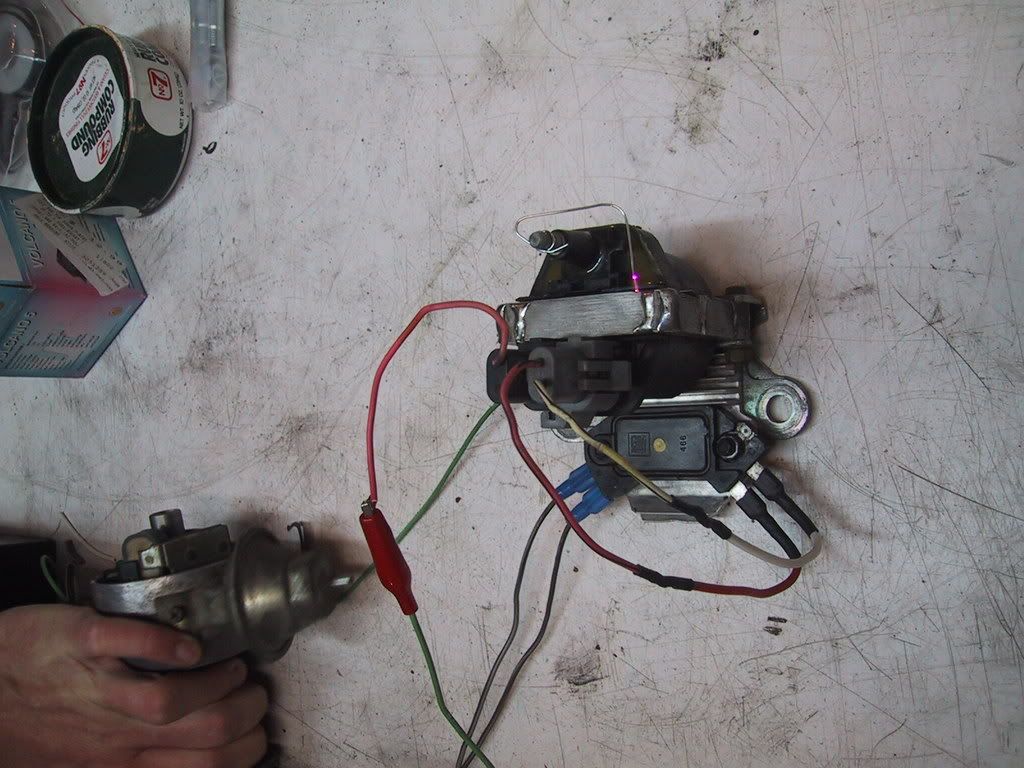

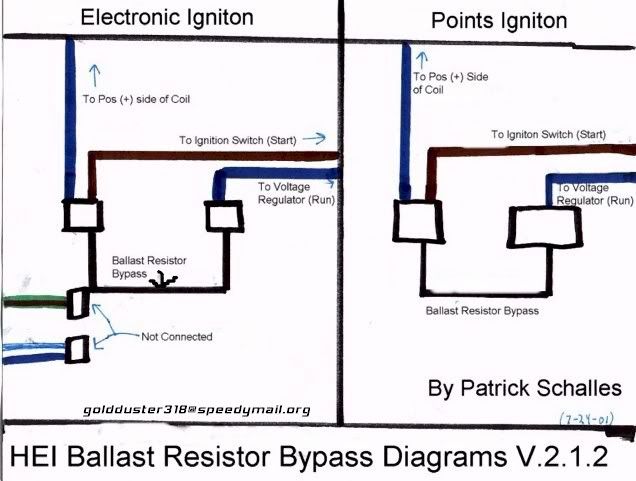

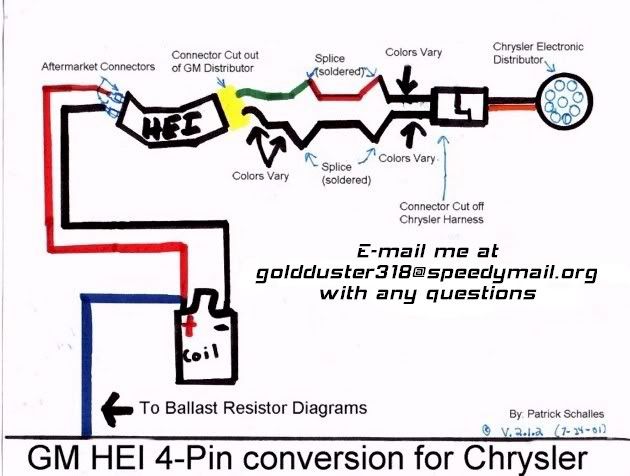

*** Used the following WD's as a guide ****************

Note: THESE ARE NOT MY DIAGRAMS, THEY CAN BE FOUND IN

THIS SECTION AND ON THE NET.

You will find full w/d in your manual and a good w/d for this

conversion in the previous post in this section. Your best

course of action is to GET familiar with Your car/truck

by reading YOUR Owners Manual.

---------- Thanks to those who uploaded them -------

--- Will upload a simple W/D showing led's and pwr relay

when finishing post ----

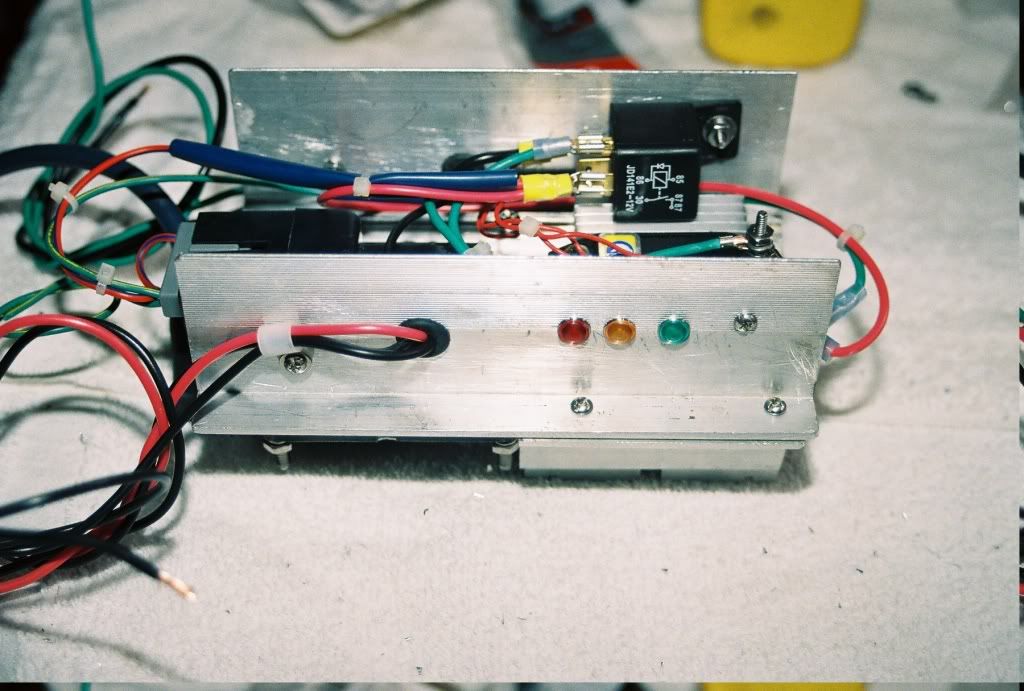

Don't like testing (lazy) so added led lights to tell

me when i have

RED........fused main batt voltage to unit

AMBER....ingition switch on

GREEN....output relay power to coil and hei unit

"NOT REQUIRED FOR UNIT FUNCTIONALITY"

Note: [led's are internally resisted, so you don't have to worry

about installing 12v resistors for the led's]

power consumption of leds will not effect full batt

voltage to relay/coil/hei unit as the draw is

extremely small. Will add wiring instructions for them

as this post matures.

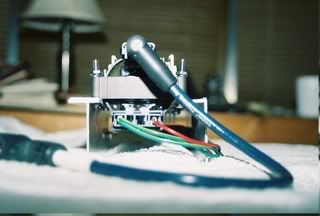

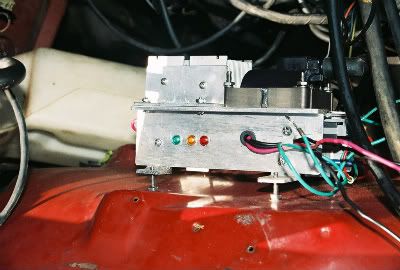

Fabricated tabs to hei module to fit on firewall

http://i1138.photobucket.com/albums/n53 ... 024A-1.jpg

Step 7

Install/ test New Distributor and Ignition Module

Make sure you spend the time to "find" TDC "top dead center"

prior to removing the old and installing your new distributor.

(Many posts here and in your manual will guide you)

Removed old coil, marked +/- wires with pen & masking tape

Removed old Distributor and Installed new distributor,

Notes:found timing slot on NEW distributor

hold down mechanism slightly smaller than the hold down bolt.

Hold down mechanism are different from my stock 83 D-150

and the older version distributor pictured as parts bought

(probably mid 70's). Therefore, used a small round file to

edge out the slot so that the hold down bolt would fit enabling

the distributor to move freely from full retard to full advance

positions. (Didn't take much too accomplish this) Don't panic

if yours is a little tight also, just use the old round file.

Look at the connector coming from your new distributor.

If its a Dodge/Chrysler it may have (this connector see pic on my

new dist) Don't know the name but it is a male/female prong

socket type. Many 70's and 80's Dodge truck and vans

(turn signal, parking, and stop lites) have this connection.

I simply cut one from some of the junk i have and splice

to wires that came with your new dist. WALLA-A Quick

disconnect. You will find this handy in the future

when removing the dist or the hei module you

just fabricated.

http://i1138.photobucket.com/albums/n53 ... 4-012A.jpg

Another quick removal trick, when selecting the fender well site

you r limited by the length of the coil leed to the dist. I

fabricated module mounts so that the hei module could be

removed quickly for repair without fumbling

with the underneath firewall bolts.

http://i1138.photobucket.com/albums/n53 ... 023A-1.jpg

http://i1138.photobucket.com/albums/n53 ... 4-021A.jpg

I used stainless fittings because its important to achieve and maintain

good grounding. It won't rust. Keeping the unit away from

fender well allows moisture and small debris to roll under unit.

Complete module install on firewall.

Test Module w/LED Installed:

Make sure module ground wire is connected to GROUND

on module bolt fender well

(fabricate a jumper of #12 copper wire with a couple of alligator

clips).

Connect one end of alligator clip to the 20A fused wire from

pos (+) side of battery. Briefly connect other end to main

12V side of module. This would be the main Input to the

secondary or hi side of the power relay.

You should see the module "RED LED illuminate"

and no others. You should not hear a relay actuation sound.

(RED LED is wired from secondary side relay input to ground

via an internal resistor) Indicating battery availability.

Disconnect jumper from battery

Find (+) coil wire previously marked with masking tape

during coil removal. Connect this wire to the low side of

the power relay.

Turn ignition switch to "ON" "NOT START" position.

This will allow ignition voltage to flow through the

primary side or low side of the relay to ground,

thus actuating the secondary side relay switch.

However since battery power is not connected

via the jumper no RED OR GREEN LED will

illuminate, only the "AMBER LED" illuminates.

You will hear the power relay switch activate.

Turn ignition switch OFF

Reconnect the alligator jumper from the 20A fused

battery power to the HI side or Secondary side of the

power relay

You should see the RED LED illuminated constantly

Turn the ignition switch to ON

You should see the RED LED, AMBER LED and the GREEN

LED illuminated and the sound of the relay actuation.

ALL LED's should remain on!

Start Motor.

Test Module w/out installation of LED's

Testing module without LED's simply connect as

described with LEDS.

Start motor.

If motor runs you can plan your wiring harness

permanent installation.

Note: Assuming you fabricated and wired

the module correctly, installed the carb, and

distributor correctly the engine should run.

Only problem i had was I had to reverse the

wires coming from the Distributor to the hei

module, after that I thought I had a turbo charged

slant/6. Good reason not to permanently

wire anything except module until engine runs.

Final Clean up of wiring harness w/o removal of old EFCS

wiring.

Simply finish hard wiring what you got and clean up the existing

wiring harness.

Final Cleanup of wiring harness with removal of old EFCS

wiring. Following description is what I did. There are many

many possibilities here.

Understand your own vehicles options as they relate to the

electrical,emission,fuel,vacuum etc systems.

Decide what it is you want to be left with at the end of the

conversion.

Once I completed this I opened up the wiring harness

by cutting the harness tape and spreading the wiring

out. For your ignition module you only needed the

ignition wire from the coil and a fused power supply

from the battery as well as good grounding and the

necessary connections to the distributor.

Once you "OPEN" up the wiring harness the layout

of the lean burn system appears straight forward

despite the amount of wiring I planned on

removing.

My plan was to remove "ALL" the lean burn system.

In addition I wanted to remove the electric choke,

electric temperature and oil pressure senders and

gauges. This would leave a pretty sparse and simple

electrical system under the hood.

* working on w/d and resizing pics, processing

more pics, adding links to

load quicker jeff 08/12/11

------ continued --