As someone who has been very involved in design, machining, and manufacturing for a very long time, I think I should put some perspective on this thread.

First off, $60.00/hr machine time is very reasonable these days for any kind of machine work. Just today I picked up a quote for a small brass part based on $120.00/hr on a Swiss type CNC turning center...although this quote was without any setup charges. Most shops charge $75.00/hr for time on machines that cost between $40-125K without tooling and have lease payments of between $1200-$2500/month not including all the other overhead of the shop. I charge $40/hr on my machines and I have virtually no overhead since my garage is mine and the machines paid for...alas, I don't have a large CNC mill though, just a tiny one. But I do run production on an automatic lathe, and work daily in a large production shop.

Second: If the shop has a machine with any kind of time saving or machining enhancing devices...(rotary table, 5th axis, etc.) its going to be on the high side for costs, both machine cost and cost per/hr because of the added capability and specialty.

Third: One hour setup time is extremely reasonable given the complexity of the machining operations you are expecting with this project.

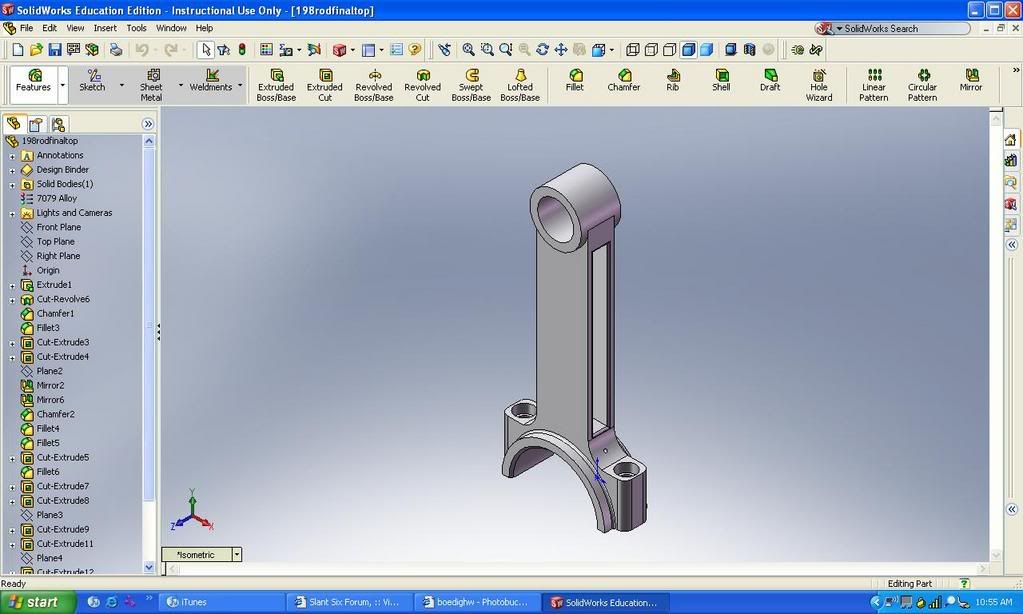

Changing from a parabolic design to an H-beam has added two more setups and at least one tool change operation to the rod, which also means having to setup and touch off one more tool during initial setup.

Third and a half: Set up for the types of operations in this kind of project will typically consists of having to build some form of fixture to hold the part for machining. So you take a slab of aluminum or such and drill and thread a couple holes probably in the center to center points of the pin and journals, times 6 so you can machine six rods at one time. Most likely, you will also need to have some kind of shoulder so that the rod blanks can be indexed 180 degrees so that both sides will machine precisely. Keep in mind also that the operation to produce the rod blanks is complex as well...

Fourth: Just to get to the point of having rod blanks, you must take an expensive slab of steel and cut the end off at the rod cap parting line, or two separate ones, that when combined add up to a slab width slightly larger than the total rod length, end to end. Precision machine each surface of the rod cap parting line, clamp the pieces together, fixture the entire slab vertical, then drill, counter sink, counter bore, and tap for connecting rod bolts times twelve for six rods. Now thread in the rod bolts, and cut through the slab five times to create six rod blanks. Don't forget to clean everything of chips between operations.

Fifth: Now you have six rod blanks, with rod cap parting seams bolted together. Set up a fixture to drill and ream precision holes to locate the blanks on the milling fixture made in part "third and a half" of this diatribe.

Sixth: Mount the rod blanks and mill the profile for one side

Seventh: Clean milling area and reverse rods to mill the profile on the other side. Remove rods and prepare to create pin and rod bores.

Eighth: Did I mention you now have to build a fixture or rig up a fixturing method to be able to bore the holes, because the rods were bolted down through the index holes previously created for the profiling operations. Now we must hold the rod some other way to be able to drill, bore, ream as needed.

Ninth: Mount blanks or blank if one at a time, and create your bores. Then you did remember the bearing tang indexes didn't you...so unbolt the cap and rod, and fixture them so that you can create the tang slots.

OK, maybe done now except for heat treating? Stress relief(shot peening). Then of course, you need to finalize your rods by resizing them on a Sunnen or equivalent rod honing machine.

Keep in mind this description is for parabolic rods not H-beam, that would take two more operations.

Oh yeah, are these rods bushed on the pin end?

There are many ways to skin a cat...I typed this as fast as I could thinking on the fly...possible to save a couple steps, use different operations depending on machine capabilities or preference of machinist, certainly...but I think your quote was a steal, and I would jump on a few sets before they regain sanity.

I don't mean this to burst anyones bubble, but without significant machining experience in a manufacturing setting, and a thorough understanding of the costs involved in operating a machine in a high overhead environment, or the costs of tooling those same machines, deciding whether something is "reasonable" in cost is stepping out of your field of expertise.

It is easy to learn Solidworks, but difficult to gain the knowledge to understand manufacturability or time and cost based studies of production.

Gearhead

|