To all of you who said vacuum leak you get the trophy. It was a series of small things that caused it but suffice it to say it was a leak at the bottom edge of the intake.

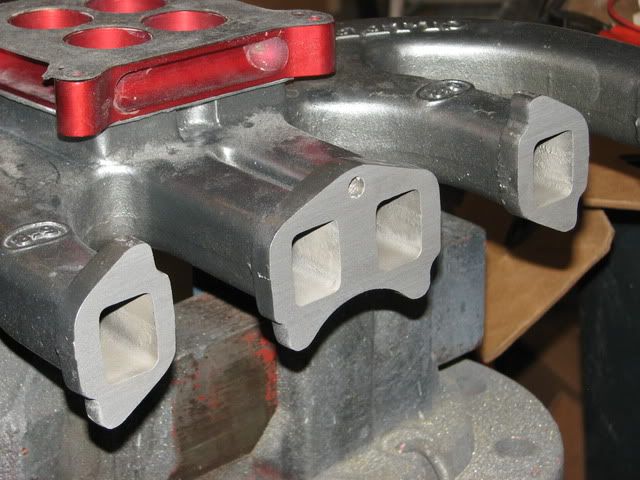

When I removed the intake and headers to check for obstructions, I noticed carbon leaking by the gasket at the bottom of the front 3 exhaust ports. Since this was a new Cox Brothers, extra thick gasket, I new it could not be faced up correctly.

I spoke to Lou this morning (Thanks) and he said to make sure the intake and headers slide onto the head without any friction. So after cleaning the head surface I slid everything into place with out the gasket and snugged it all up. That is when I noticed number 6 header tube was hitting the intake runner enough that when I snugged up the rear header it pushed up on the runner which would actually rock up the intake and cause a bad seal at the lower edge of the intake.

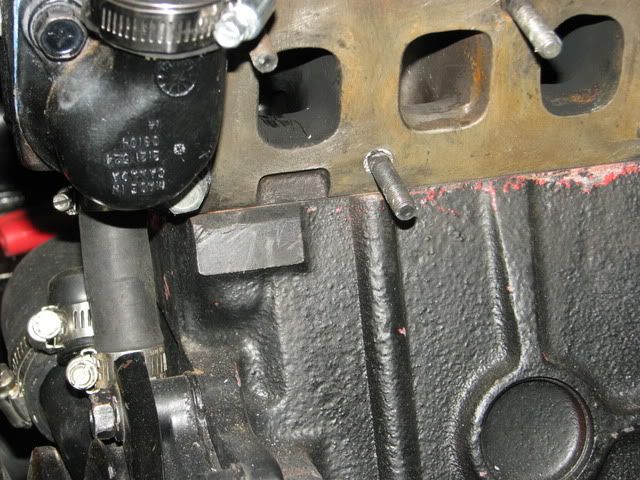

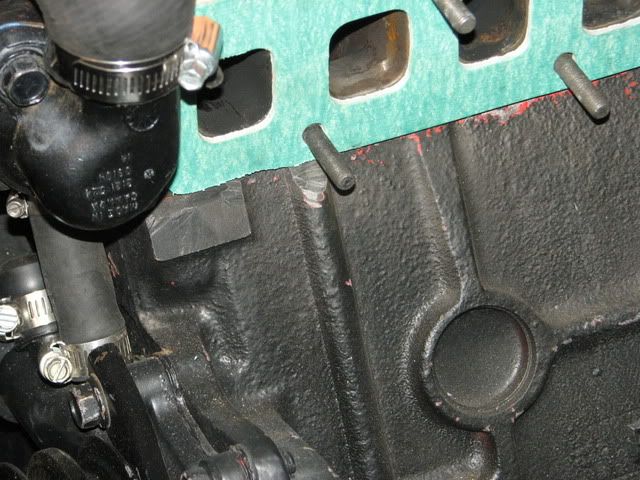

I also found two additional ribs on this 79 block that run right up to the edge of head. These ribs caught gasket and held it out away from the head. This probably made the leak worse. I ground those off and eliminated the problem.

Finally after I check the intake for flatness and reassembled everything, I noticed a couple of the triangle washers did not look like they were hitting the intake correctly. Upon further investigation, the Clifford headers are about 1/16 or a bit more thicker than the intake flange. So I took all the washers and bent them slightly so that they faced up against the intake evenly. This would have allowed me to think everything was tight when it was really only tight on the headers.

Pictures to follow later. Now I can go back and reinstall all my new stuff that has been removed trying to run down the problem.

Thanks to my slanted family for your help! I feel much, much, much better now!!

Rick

|