Quote: Greg thanks for the awesome write up with pics. I am putting a slant six with a 4 speed overdrive in my 48 Dodge Panel truck. The engine is going to to turbocharged, but nothing crazy. My question is, can I have the original flywheel redrilled without any issues? I'm just trying to save a few bucks, so I can get my hydraulic throwout bearing going as well. thanks

Hello, I have never tried to Put the Mazda/Ford 10" Pressure Plate Pattern on a Stock Slant Car Flywheel. I would imagine if you were using an 11" truck unit this would not e an issue.

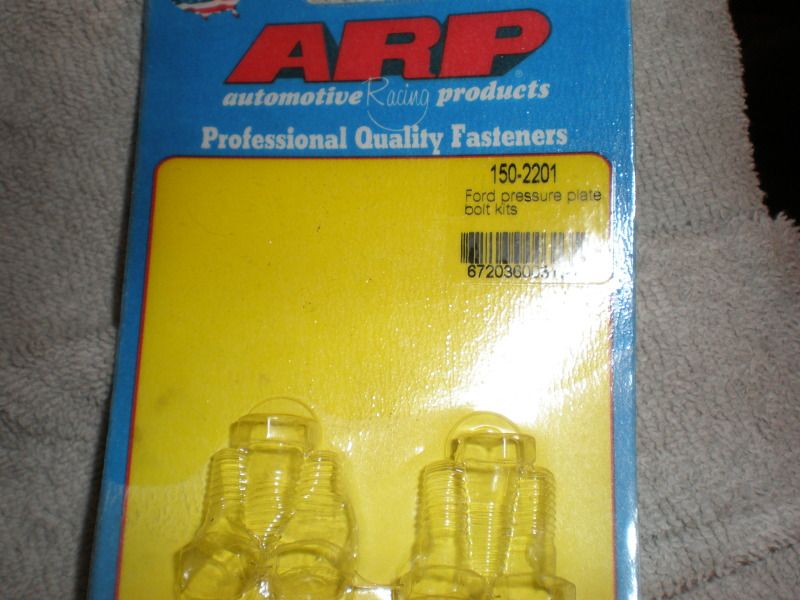

You say with out Issues... Well this particular Pressure Plate Bolt pattern sits Very Far out on a stock Slant (car) flywheel.. the holes almost hit the Ring gear.. With The 2 Steel Flywheels (one in the Dart That Has had many High 14 Second Passes on it) this setup has never had any issues..

I do not know and Cannot speculate about the Stock Cast Flywheel holding up When the Holes are Drilled so near the outer edge of the Flywheel. I do know they hold up fine in steel.

If you continue this route, get the disc and Pressure Plate Part #'s Listed in the thread from Summit Racing and then take the Pressure Plate and Flywheel to a Very Competent & trustworthy Machinist to have the pattern drilled. It has to be centered spot on. I am not a machinist, Bu I know that if that part of the whole operation is messed up your project is shot.

Best of luck.

Greg

|