Bump... Any updates?

| Slant Six Forum https://slantsix.org/forum/ |

|

| 7MM Head https://slantsix.org/forum/viewtopic.php?t=56342 |

Page 4 of 7 |

| Author: | CNC-Dude [ Wed Oct 15, 2014 3:14 pm ] |

| Post subject: | |

I'd have to look back at some invoices. I bought a bunch of sets of them several years ago along with bronze guides all at once. They weren't too expensive, about the same as a good Manley valve. Since no one makes an application specific 7MM valve for many apps other than a Chevy, they're still a bargain if you have the ability to take them to the next level. |

|

| Author: | the_engineers [ Fri Oct 17, 2014 8:26 am ] |

| Post subject: | |

Looks like custom valves from Manley are around $30 each...$360 to do a head. Is that comparable to what you'll have in them (time and money)? |

|

| Author: | CNC-Dude [ Fri Oct 17, 2014 11:04 am ] |

| Post subject: | |

I think the blanks were much cheaper than that, maybe by half if memory serves me correctly. They may have increased slightly since its been a few years now. But still a bargain I think. |

|

| Author: | the_engineers [ Fri Oct 17, 2014 3:04 pm ] |

| Post subject: | |

As you said before, if you have the tools skills to finish, then definitely a bargain. I don't, so I'm just trying to weigh out the cost of blanks/finishing verses ordering. |

|

| Author: | Dart270 [ Sat Oct 18, 2014 5:18 am ] |

| Post subject: | |

Mike Jeffrey knows how to order whatever you want custom (sizes, material...) from Ferrea. Lou |

|

| Author: | ProCycle [ Sat Nov 01, 2014 2:31 pm ] |

| Post subject: | |

Bump... Any updates? |

|

| Author: | the_engineers [ Sat Nov 01, 2014 7:25 pm ] |

| Post subject: | |

Head is at the machine shop. He's going to crack-check and flow for baseline numbers this week. I'm traveling, so I'm going on faith that it'll be ready when I get back. |

|

| Author: | Sam Powell [ Mon Nov 03, 2014 4:39 am ] |

| Post subject: | |

Fascinating new information to me about the hardened valve seats. I put them in my current engine, but now am considering leaving them out of the 1983 head I will eventually be putting stainless over sized valves in. I had a 1969 Falcon I6 that burned the exhaust valves, and my current Dart burned its exhaust valves, but I was running that first engine on the ragged edge of preignition much of the time. Ed, I was particularly taken with your thoughts about stainless being less prone to damage because of dissimilar metals. Much to think about here. Thanks to all for your insights and the time to write about it. Sam |

|

| Author: | the_engineers [ Wed Nov 26, 2014 1:26 pm ] |

| Post subject: | |

Brief update... I stopped by the shop today. Unfortunately, he's not having great luck finding guides that seems to fit all of the criteria. Right now, he's got a set that are installed on the intake/exhaust guides in on cylinder #3, but he said they're loose, even before he's had a chance to size them. Should be good enough to start doing some flow work, though... |

|

| Author: | CNC-Dude [ Wed Nov 26, 2014 3:24 pm ] |

| Post subject: | |

Here are the options you have. You can buy guide blanks and machine them to fit the head or start from scratch and make the entire guide yourself. Here are the ones i'm using, I just bought 7MM guide blanks when I bought the valve blanks.

|

|

| Author: | the_engineers [ Fri Dec 05, 2014 12:58 pm ] |

| Post subject: | |

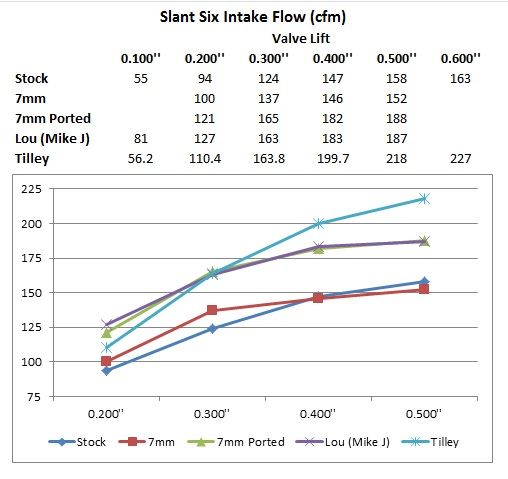

Well, the two test ports are under the knife. I spoke with the machinist today. He has the intake side done, with the exception of un-shrouding the chamber around the valve. He's just starting the exhaust side. These are the numbers that he's given me for flow. I plotted them against the info that's on Dave Dutra's site. He's pretty convinced that he can get another 3-5 cfm across the board after he finishes the chamber work.  I'm pretty sure that this is first /6 head, so I feel pretty good about the results... My goal was 200 cfm. Any thoughts on where to look for the last 10 cfm? |

|

| Author: | nm9stheham [ Fri Dec 05, 2014 2:35 pm ] |

| Post subject: | |

Odd that the 7mm flows at higher lifts would be at/below the stock while higher at the low lifts...... Have you had any thoughts on that oddity? |

|

| Author: | Exner Geek [ Fri Dec 05, 2014 3:33 pm ] |

| Post subject: | |

Nice information here. The head I had ported by Glen Knowlton showed 192@.5 and 197@.6 with a 1.78 valve. The best I ever saw was Dave Evans which used 1.88 valves with 3/8" stems I believe. He showed 214CFM@.5 and 217@.55. I think Tilley had 1.84 valves. He told me once that he used a wall thickness checker to determine where he could remove more material under the valve without breaking through, a real hazard when looking for that last CFM. |

|

| Author: | Rick Covalt [ Fri Dec 05, 2014 3:48 pm ] |

| Post subject: | |

Did Cameron do something more to gain that 30 cfm over the Jeffrey head? Or is it due primarily to the bigger diameter? I'm guessing they are all run at the same differential too? Rick |

|

| Author: | the_engineers [ Fri Dec 05, 2014 6:01 pm ] |

| Post subject: | |

I assume that the 7mm stem allows the air vortex to form quicker, boosting low lift performance...again, just a guess. The 7mm line is "as cut", with no blending, etc. We flowed at 28", which is typically a standard. I have a sonic meter and we talked about thickness checking...it'd be a little tight trying to get the meter head into the bowl, which is where the most work still needs to be done. Pics as soon as the head is back in Lincoln... |

|

| Page 4 of 7 | All times are UTC-08:00 |

| Powered by phpBB® Forum Software © phpBB Limited https://www.phpbb.com/ |

|