Quote: That would mean that the Gear on the Distributor wants to turn clockwise as it is fitted to the Gear on the Camshaft.

Correct.

Quote: The Distributor Cap that is on the NEW Electronic Distributor has one of the Spark Plug Towers labeled as Number One.

True, but as a matter of mundane trivia, plug wire placement is entirely arbitrary so long as the 1-5-3-6-2-4 firing order is observed. The cam doesn't care where the rotor is physically pointed, so long as the rotor fires off the right cylinder at the right time. but you should probably just used the terminal labeled "1" for simplicity's sake.

Quote: So when the Electronic Distributor is installed, the Rotor wants its Terminal's Right side at the Left side of the Number One Terminal in the Distributor Cap.

Sure, that will work.

Quote: This can be done with some amount of precision because there is on hand a Distributor Cap with the top cut out of it, and it can be put on and with the Rotor pointing at Terminal Number One on the Cap, the Distributor can be turned so that the Rotor is where it should be as described above.

That will make it much easier to ballpark the timing.

Quote: [10 BTDC is]quite a bit MORE than Lorrie is specified to have. Specifications on Lorrie's 225 Slant Six are Number One Piston fires at TDC. But Daniel says to advance it to five degrees BTDC.

Sure, 5 BTDC is good too.

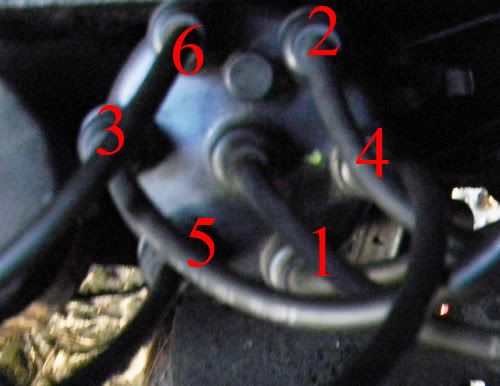

Quote: Have been looking at the Electronic Distributor and have noticed that the Reluctor has vertical Ridges on it, and that the in the middle of the Pick-Up Coil Assembly that there is a single Ridge on it. Would it be safe to assume that when one of the Reluctor Ridges passes the Pick-Up Coil Assembly Ridge that THAT is when the Coil fires off to the Distributor?

Yes, very safe. And you don't even have to trap me into a dentist chair for me to tell you it is safe.  In fact, if you want to analogize the reluctor points to the rubbing block points, to set the timing to TDC, you want the leading edge of the rotor tip pointed at the leading edge of the plug tower terminal right when the reluctor fin lines up with the pickup fin. In fact, if you want to analogize the reluctor points to the rubbing block points, to set the timing to TDC, you want the leading edge of the rotor tip pointed at the leading edge of the plug tower terminal right when the reluctor fin lines up with the pickup fin.

Quote: Am hoping to get an understanding of what all happens when the system functions.

The plugs fire!

Quote: Anyway, at this point, just getting the Components arranged, assembled, and installed is the central focus.

And a great way to be. If it is worth doing, it is worth doing right. Go slow, be careful, do good quality work, and you will be fine.

|