Back to the Build!!

So i finally got back to working on this car.

I was able to pin point that my issue is from a vac leak, or at least I'm 95% sure...

After taking off all the vacuum hoses and trying a process of elimination. The hoses were all good, but there was a leak at the carb, line that goes to the distributor. It had pulled out of the carb when taking the line off sometime ago, and I had pounded it back in, thinking it was all good. Nope.

So I JB Welded it up, put it back on and was pumped to get it running.

The car ran much better, but it still would not idle all that well, it would want to slowly die from too lean. So I brought out the brake cleaner spray can and sprayed the intake, each runner at a time.

It appeared that the middle two runners were also leaking. So I tightened most of the nuts past the 10 ft lbs spec, and started it up.

It did improve some again, I also had RTV sealant between the flexpro gasket and still could not get it perfect.

So I took off the manifolds and put a straight edge on it, and its not perfect. So my conclusion is that since I did not pair the exhaust manifold that came with the 2bbl intake, and used the exhaust manifold that was on the car. That's what made the difference?

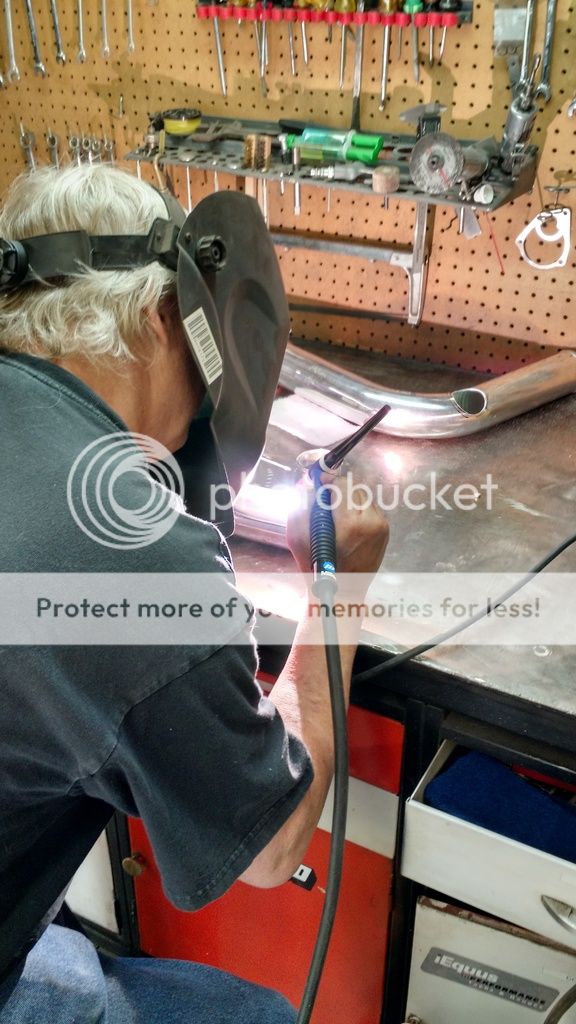

So I took the pair still bolted up to a guy who works at a machine shop to get it all trued up. I'm hoping this is my answer...? Not sure what else it could be other wise.

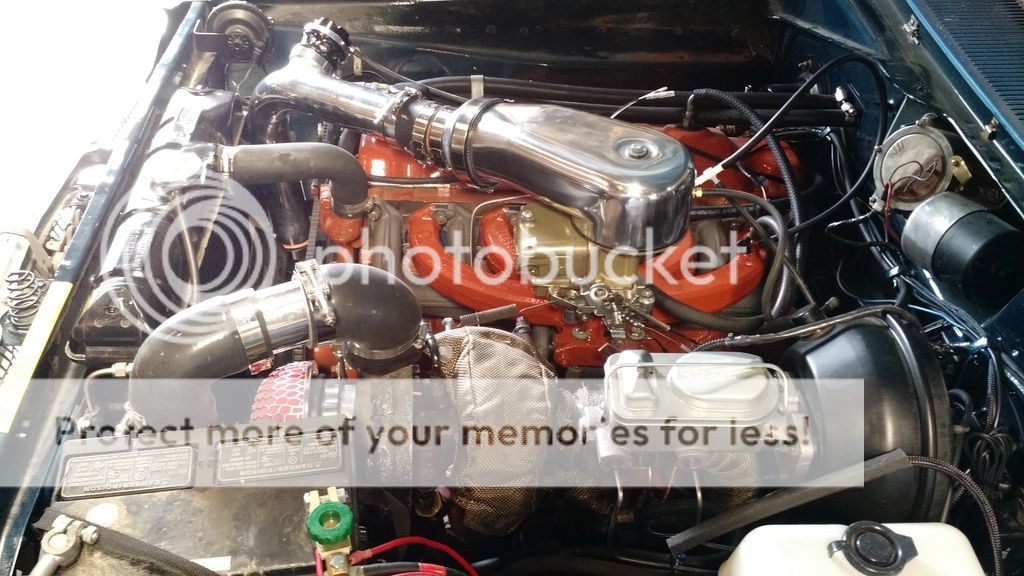

Oh... and random. My oil pressure also seemed to just disappear....? when running, my gauge shows 10psi, same with a mechanical gauge. Not sure if the line got plugged some how? It was the difference of the car sitting for 2 months since running...

I blew out the line, hopefully that's the issue.

This is T'd off the line that goes to the turbo, from the oil pump.

|