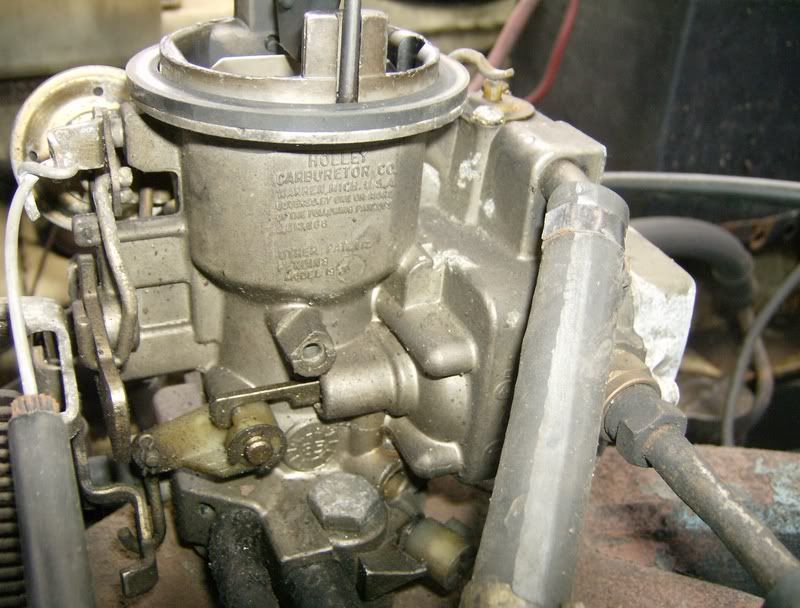

Mileage in the modified idle air bleed 1920 dropped to 20 mpg with the #64 jet. It had lots of extra power for a little one barrel!

Put the #61-2 jet back in and I am back to 23 mpg. That includes plenty of passing, stop and go, twisty back country roads and 65 to 70 mph on the freeway. Still had plenty of power and good response as well as descent mileage.