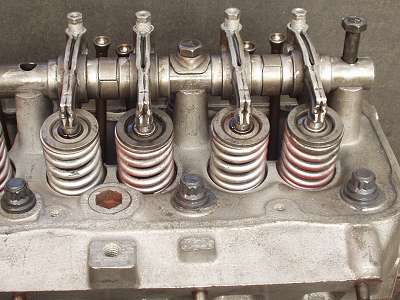

Yes, ARP studs / nuts that I currently have torqued to 55 ftlbs.

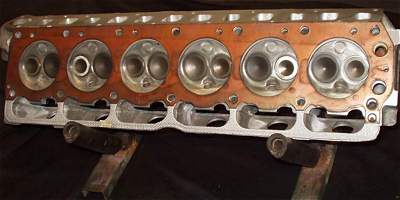

The special aluminum block head gasket received a light coating of Copper Coat spray sealer right before it went onto the engine.

I will start the engine and give it a short heat cycle, then check head stud torque, at 55 ftlbs.

Restart the engine give it a few more heat cycles, as I tune it and re-adjust valve lash, recheck all bolts, etc. then see if I can re-torque a little tighter, may-be get to 60 ftlbs. We just have to "get there" and see how it feels.

I am making good progress... have some additional photos in the camera that I will post tonight. Buster should start and run this weekend.

DD