Quote:

Do you have details that you can share about the long block? Head work? Piston selection? Cam? Compression? Long/Std Rods?

Did I miss these somewhere?

Her is some big secrets..

The block is bored 0.60 with standard pistons. Just little bigger end gap.

I also did a o ring job with stainless rings together with the Aussiespeed big bore gasket.

The rods are the stock one.

The head is ported by myself, with engine builder oversize valves, bronse valve guides and harder valvesprings.

The head is shaved 0.059 inches, (ment for a NA engine ) but after porting the chambers i have checked the chamber size, and it was about 50- 52 cc.

I think its about 8.5- 9:1 in compression ratio.

when i checked the compression pressure it was 150 psi

when the block was still empty i put the head on and turned it upside down. And with a lamp and small mirror i checked and ported the head around the chamber so it perfectly matched the bores.

And i also had to touch the cylinder bore, because of little to much valve unscrouding at the head...

The runners in the head is ported slightly bigger than stock gasket holes,also into the intake as far as i could reach. about 2 inches.

The intake and head also have dowels and holes to make sure of the exact possition.

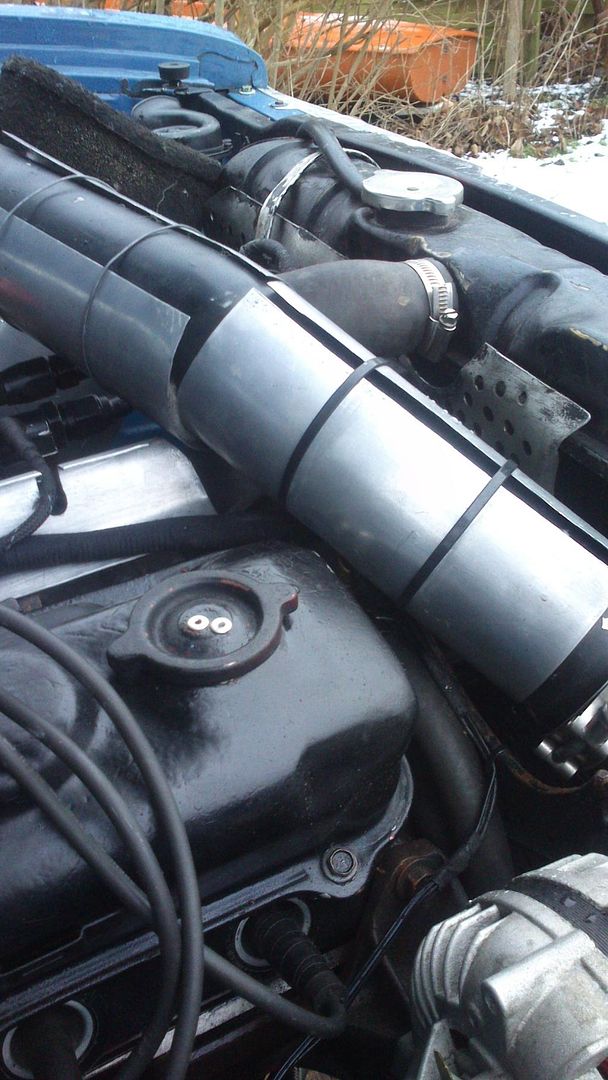

My exhaust manifold are the stock cast iron , but ported and modified.

Here is the flow diagram for the head

28"

Stock

in out

0.100 54 - 51

0.200 95 - 84

0.300 123- 99

0.400 131- 105

0.500 136- 107

ported

0.100 69- 54

0.200 115- 94

0.300 156- 121

0.400 169- 137

0.500 173- 140

The camshaft is a Howard stock 256 220@ 0.473 lift with 110 lsa

The exhaust system is 3 inch from the turbo, and then it splits into two

2 1/2

and go into the muffler. The last part over the rear axle is a single 3 inch pipe. Quite free flowing.

Hope there was anything interesting . Its Always fun to see engine - car build spec

Have a nice day or night..

Thomas

[/img]

[/img]