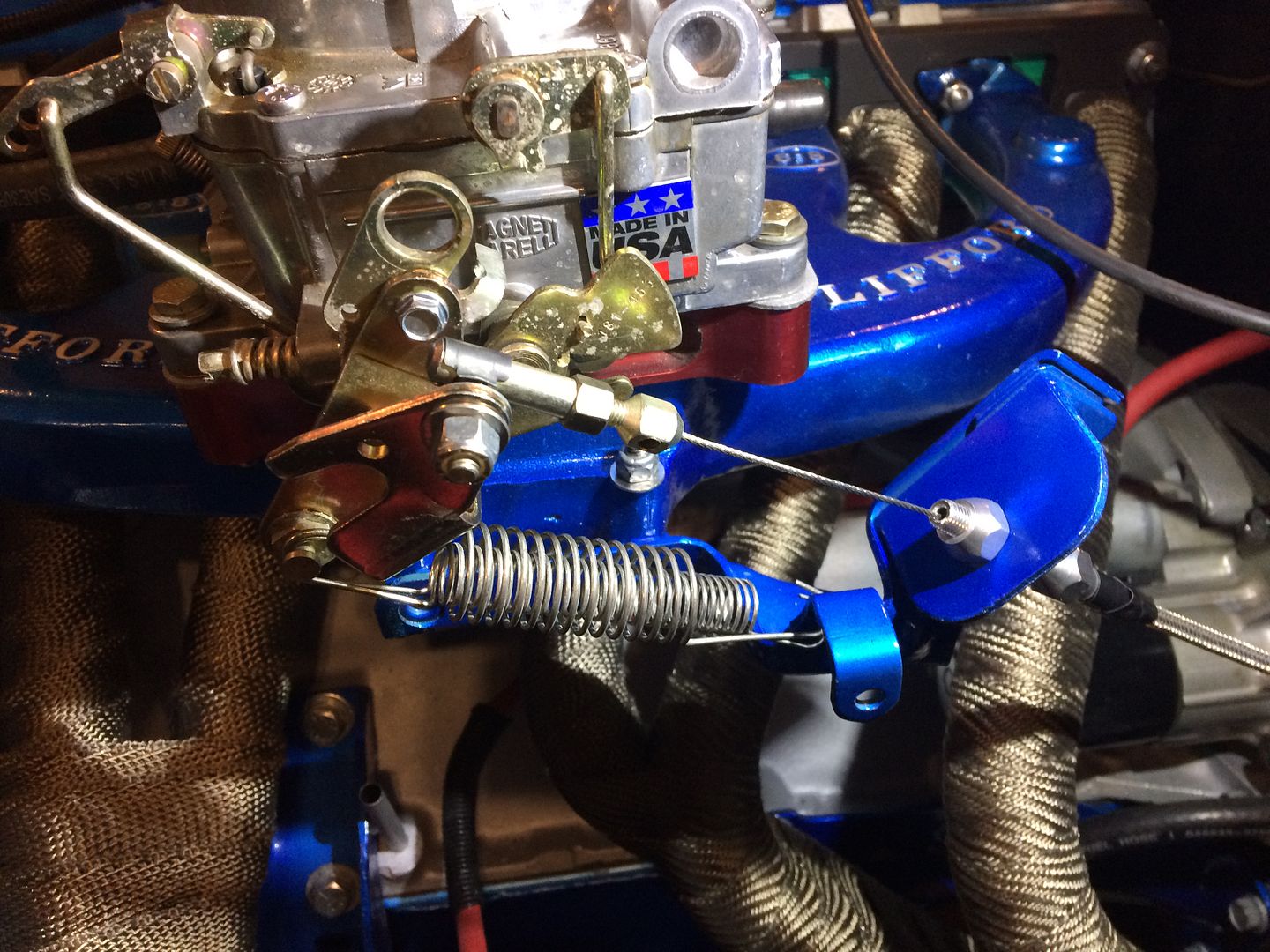

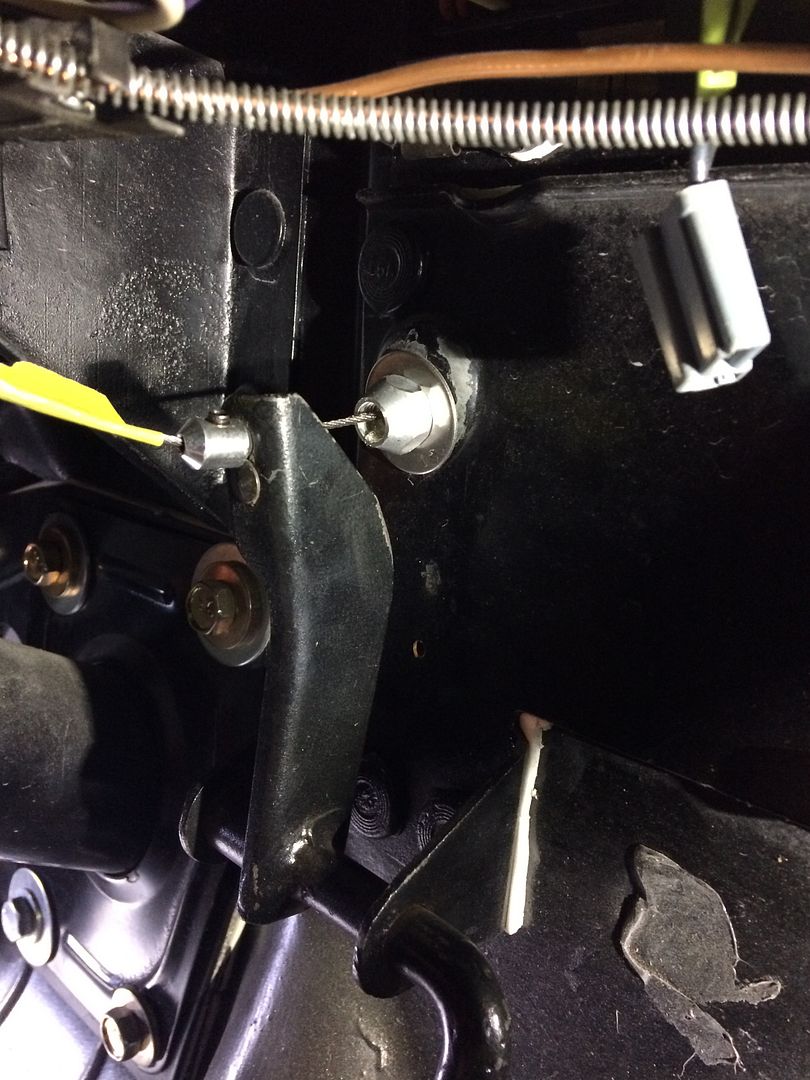

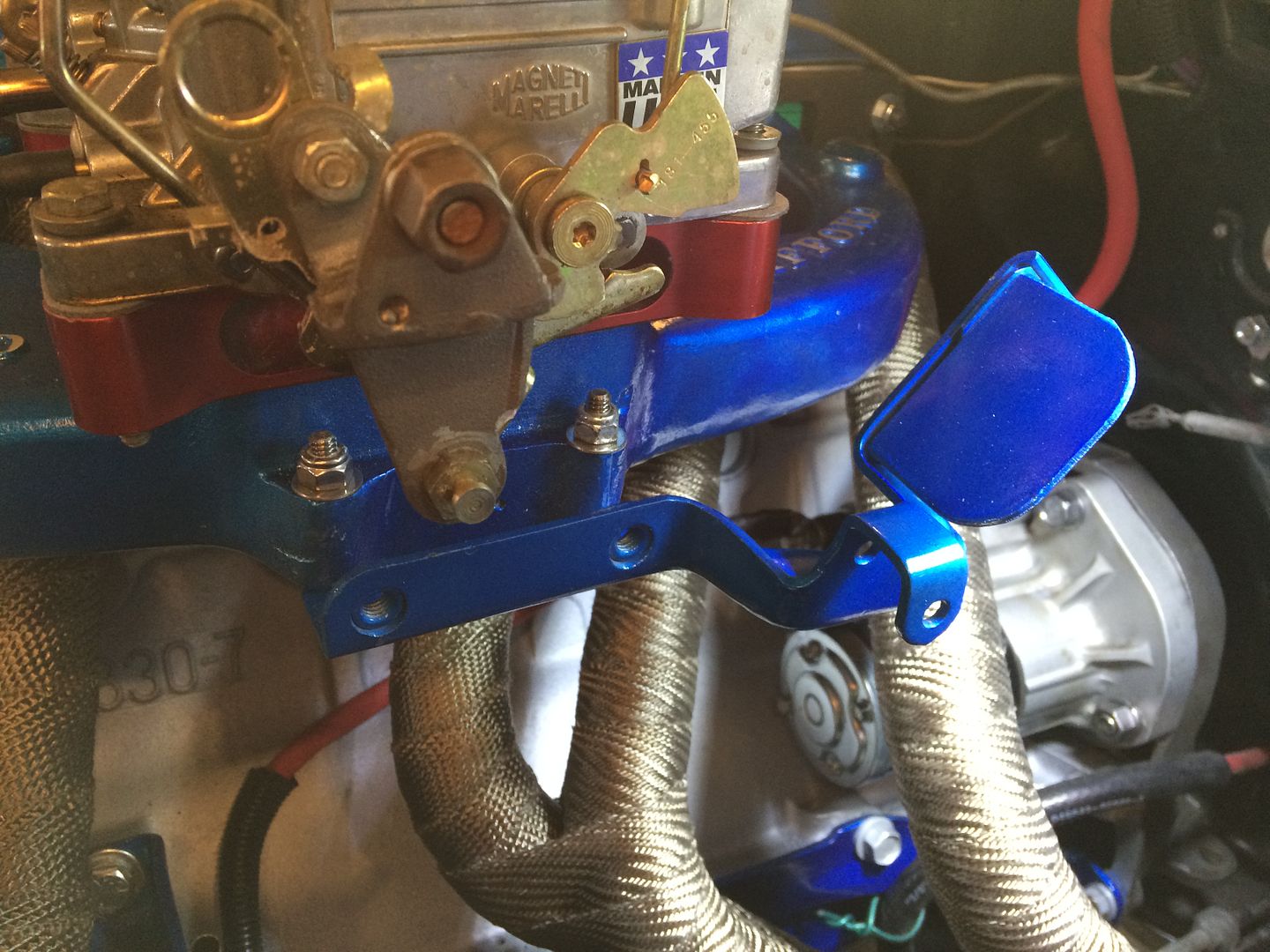

While I was swapping to the new race motor I wanted to change the throttle cable around to have a little better angle to the carb. I started with the factory Super Six bracket, and removed the factory cable clamp. I took a piece of aluminum angle and cut it and notched it to fit snugly in the bracket. tightened down the factory hold down nut and the bracket is ready for the new cable.

I gave it a coat of paint and mounted it to the engine. I am actually going to use a Gearhead kickdown cable as the throttle cable. It has plenty of adapters and lots of adjustment points and I think it will work well. All I need to do is drill a hole in the bracket for the cable and it should be good to go. No kickdown is needed since I am using a full manual valve body.

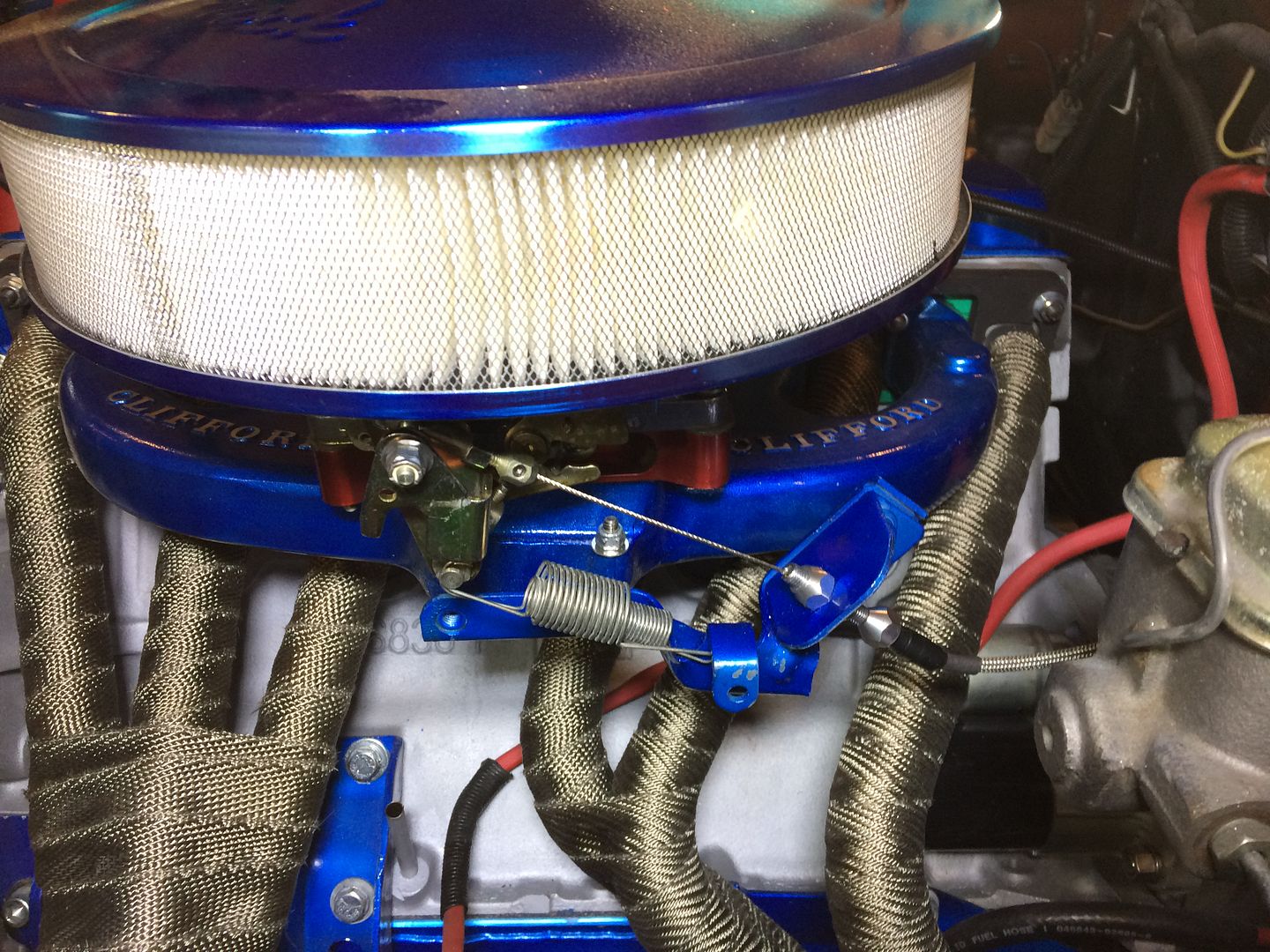

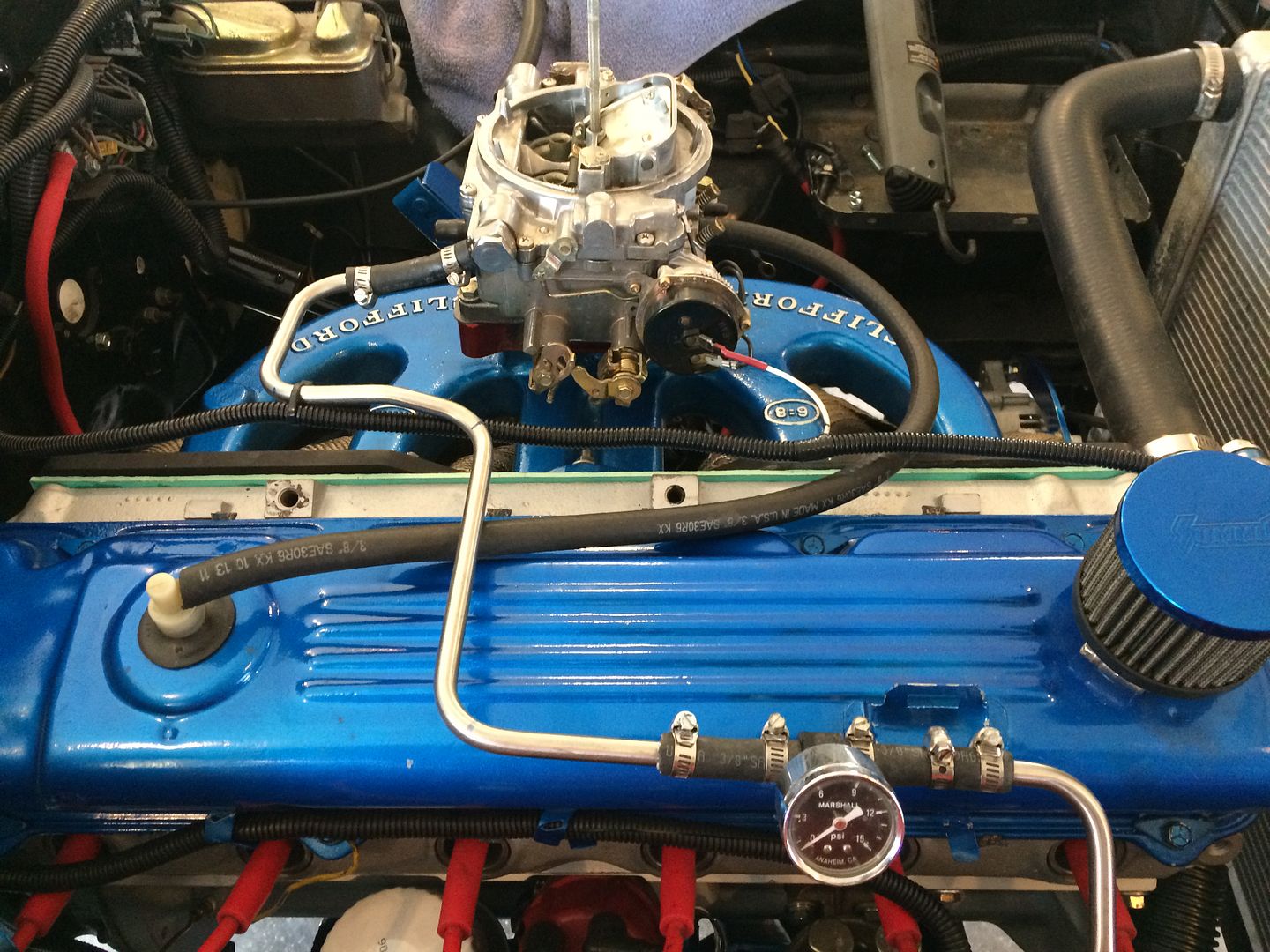

I bent up a new piece of stainless steel fuel line from some scraps I had. I was able to clamp it off to the factory bracket on the top of the valve cover

I repainted the chrome air cleaner cover with the blue anodized paint. All I think is left is the throttle cable which will be here Tuesday and top off some fluids. Then we should be ready for start up!