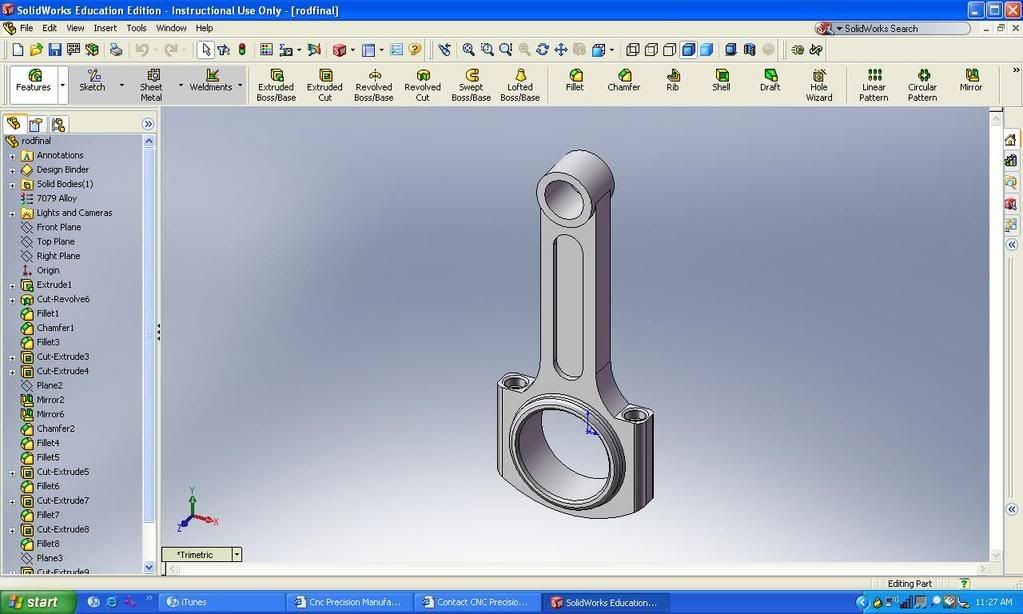

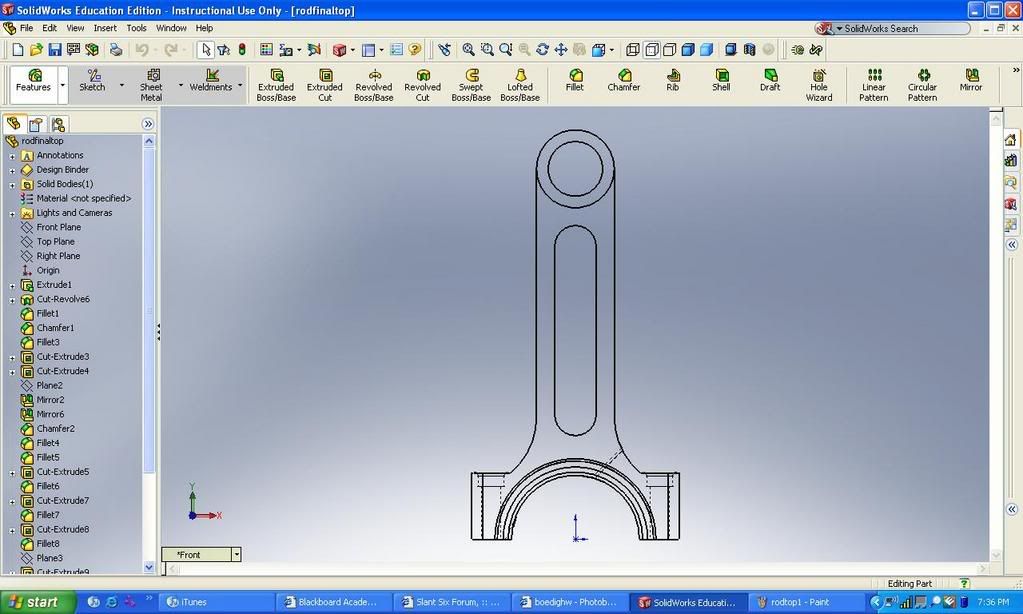

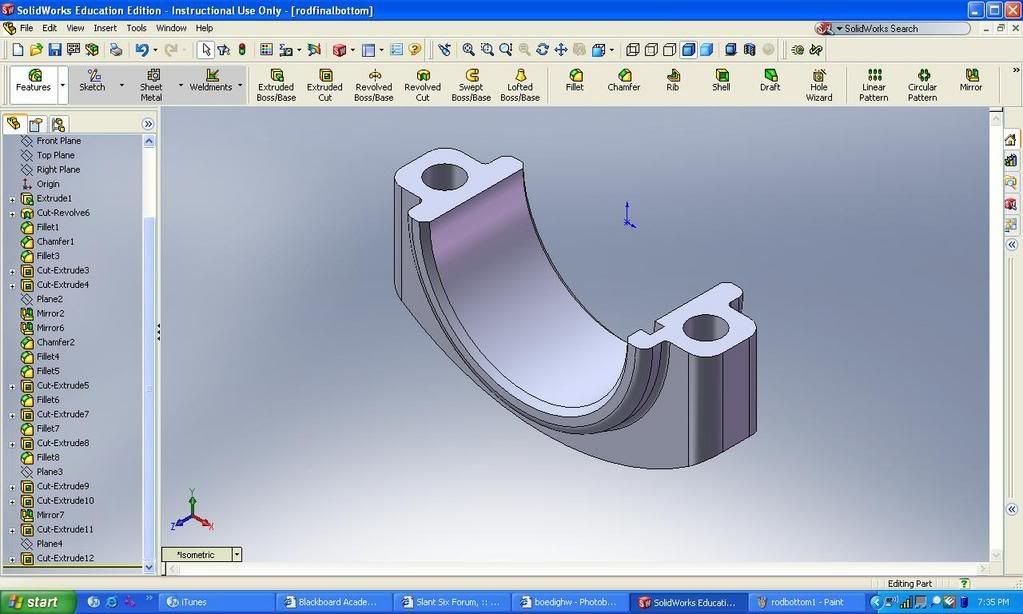

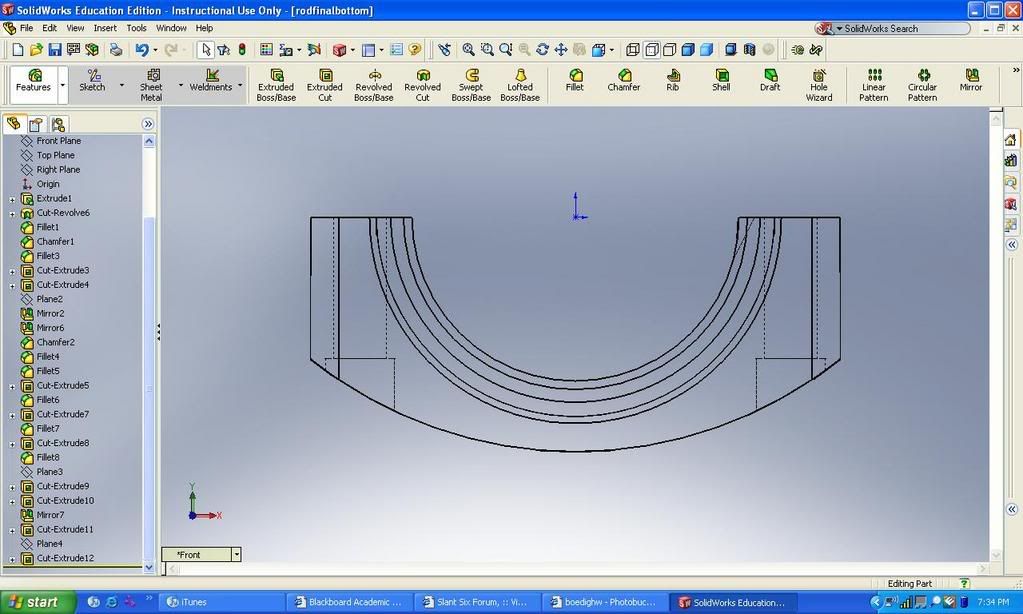

Well, I metioned this in the parts for sale area and it started some commotion so I thought I would pass it on to this area. Dad got medically retired this last year and wants to play with CNC at home. Being a slanter fanatic I proposed some quality performance parts as a basis of his home business. These would be availible in both 225 and 198 billet aluminum. I don't quite know what material or how to heat treat them. I've contacted a company in sherwood to cut the first set if the price is fair. So any ideas or design ideas or anything drop a line.

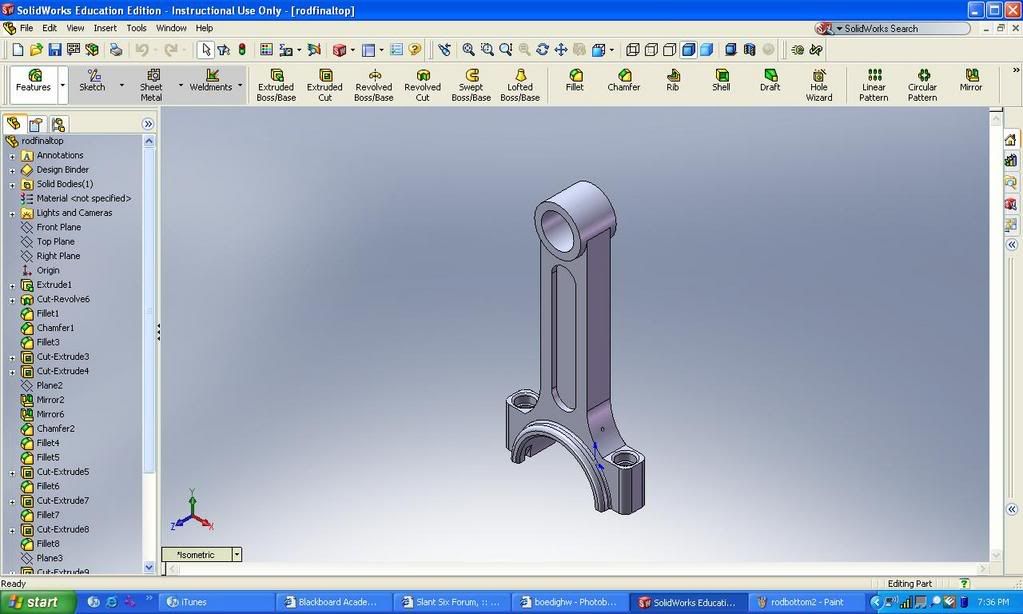

http://s236.photobucket.com/albums/ff144/boedighw/