Yes, you're on the right track. I used jargon in calling that chart a truth table; my apology.

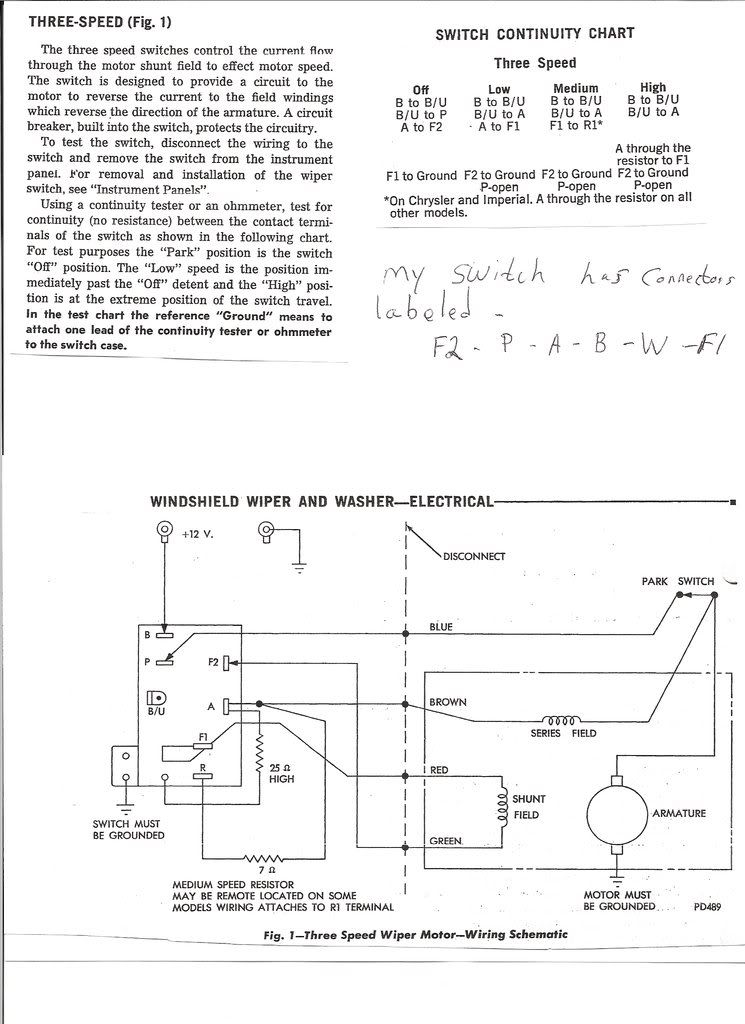

Since B and B/U are always electrically the same, I suppose yours just lacks the B/U pin; don't worry about it (it's probably just an output on the low side of the internal breaker and was used to power an external wiper switch). W is usually for washer; it should short to B when the shaft is pushed in (maybe not in OFF).

If B doesn't connect to anything, the internal breaker may have broken. If the bimetalic strip's spot weld broke, it's very hard to fix - I'd short it out and just use an external auto-resetting breaker in its place. If the points are just burned, you can clean them.

It is best to use a multimeter with buzzer or a self-powered test light; you want all connections (except the resistor) to be less than 1 ohm; the resistor less than ~30ohms (probably - I don't have the FSM in front of me). It should change when you rotate the shaft.

Just follow the chart. For example, with the switch in LOW, B-A should short (0ohms), F1 ought to go through the variable reistor to A (0-~30ohms), F2 ought to short to the case (ground), P ought to connect to nothing.

Check all the positions; don't be fooled by flaky connections; here, you need <1ohm for everything but the resistor; anything over 1K ohm is essentially open, but I'd expect you'd see at least Mohms or offscale for opens. I'd test each position a couple of times to make sure they're reliable.

If you find a poor connection, you can

1) get a new switch (similar switches might work, but check the charts and pinouts 1st!)

2) fill it with WD40 and try to clean it that way (drain it before putting it back)

3) take it apart carefully and try repair it

I've had good luck with #2. Unlike many switch cleaners it doesn't attack most plastics, but it is *slightly* combustible so I'd drain it first. Other people may give you other advice, but my experience with has been excellent.

#3 requires a lot of patience and care not to loose the little springs & balls that will want to shoot out. With it apart, you can use agressive contact cleaners & preservatives on the metal contacts. You might want to glance at http://www.tidewatermoparclub.com/TECH/dimmer3c.pdf as an example of fixing something similar.

I've done a couple of 2sp/3sp hybrid systems, and I do not recommend you try to convert to 2sp or hybrid; it's a lot of work.

|