All of the above.

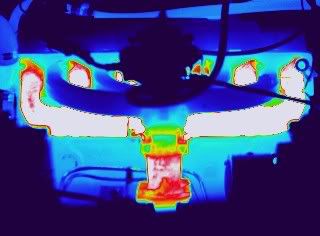

Note the temperature differences in this thermal image:

This ONLY shows external IR energy in the 8-14 micron range, converted to a false image, etc, technobabble blah blah blah. White is the hottest, fading into red where it gets cooler, blue is cool, black is coldest. In this image, the engine had been idling for a good while (180F thermostat, IIRC). The high temperature, on the exhaust manifold between 2 and 5, is 208.2C. The lower part of the intake, where it connects to the exhaust, is about 113C. At the end of the runners, the intake is about 76.3C. The head and block are running 80-100C. Interior temps would no doubt be higher on the exhaust

Detroit Wonder Metal (cast iron) can take higher temperatures longer than aluminum can, as already stated. The intake sees significantly less heat than the exhaust. Aluminum blocks use iron liners, exotic coatings, and/or carefully designed coolant flow to carry the heat away from the cylinders.

I'll have to figure out how to get some temperature data displayed here - it's embedded in the original image, but uses proprietary software to display. If I can post a .pdf or MS Word document, that'd work.