Try a new vacuum gauge!

Seriously, does the engine run well, or poorly? An engine idling at 10 inches of vacuum should be running very poorly. And where are you hooking up your gauge?

| Slant Six Forum https://slantsix.org/forum/ |

|

| Missing vacuum https://slantsix.org/forum/viewtopic.php?t=34381 |

Page 1 of 2 |

| Author: | JeffDavis [ Thu Mar 19, 2009 6:35 am ] |

| Post subject: | Missing vacuum |

I can't seem to get more than 10" of vac. out of my '64 /6. Got a new carb. and distributor. Timing is right, fuel/air mixture adjustment won't get me to 20". Used ether to look for vac. leak and can't find one. Checked and adjusted carb. correctly. Double checked valve lash, last time it was warm and running. Any one got any ideas how to get more vac. out of this thing?" Thanks, Jeff |

|

| Author: | Reed [ Thu Mar 19, 2009 8:04 am ] |

| Post subject: | |

Have you checked if the outer ring on the vibration dampener has slipped? If it has, you may be setting your timing to the wrong base setting. |

|

| Author: | JeffDavis [ Thu Mar 19, 2009 9:38 am ] |

| Post subject: | |

Yeah that's been checked. Still lines up at tdc. Jeff |

|

| Author: | Reed [ Thu Mar 19, 2009 10:12 am ] |

| Post subject: | |

Well, then you have a vacuum leak somewhere or your vacuum gauge is faulty. 10 inches is way too low for everything else to be right but there to be no vacuum leak. I would start by making sure all the hose nipples on the carb are properly hooked up and/or plugged. Then I would start looking at the gaskets on the carb to make sure no holes have been left open. After that I would pull the intake manifoldand reinstall it using the proper proceedure. See here What driveability problems does the car exhibit? A car that gets 10 inches of vacuum at idle either has a serious racing cam installed or a serious vacuum or timing propblem somewhere and will exhibit problems when driving at low speeds. |

|

| Author: | SlantSixDan [ Thu Mar 19, 2009 10:26 am ] |

| Post subject: | |

Try a new vacuum gauge! Seriously, does the engine run well, or poorly? An engine idling at 10 inches of vacuum should be running very poorly. And where are you hooking up your gauge? |

|

| Author: | JeffDavis [ Thu Mar 19, 2009 11:20 am ] |

| Post subject: | |

Good idea, I'll try a new one tonight. Hooking the gauge up where the vac. advance was before I unhooked a plugged it. Jeff |

|

| Author: | Reed [ Thu Mar 19, 2009 11:50 am ] |

| Post subject: | |

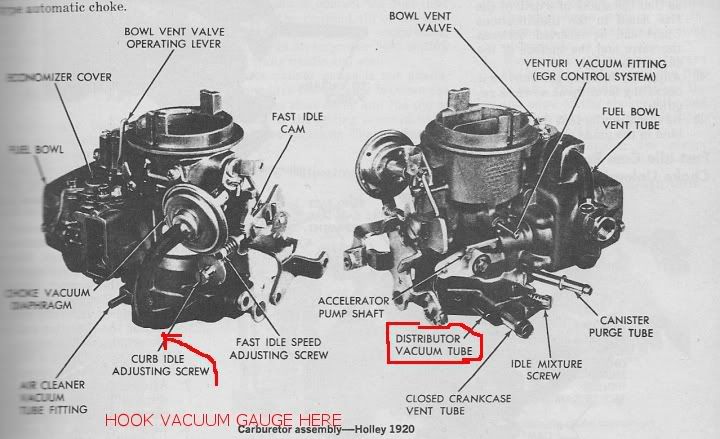

Uhhhh, do you mean you are hooking the gauge up to the ported vacuum source on the side/base of the carb? What carb do you have and please describe, to the best of your ability, the location of the vacuum nipple you are attaching the gauge to. A better location to attach the gauge is the port for the choke pulloff diaphragm. Another thought, is all else checks out and your gauge is good, is that the rotor might be 180 degrees off. Cylinders 1 and 6 reach TDC at the same time, and the timing mark will be at TDC on both cylinder 1's TDC on the compression and exhaust stroe. I once bought a slant six powere car where the previous owners had managed to put the distributor cap on 180 degrees off. The motor ran, and ran smoothly, but it lacked power. |

|

| Author: | JeffDavis [ Thu Mar 19, 2009 12:26 pm ] |

| Post subject: | |

Reed, yes the gauge is hooked up to the ported vacuum source on the side/base of the Holley 1920 carb. However when hooked to the choke pulloff diaphram it didn't appear to make a difference. I don't believe it's 180 out. When the harmonic balancer shows tdc (on the compression stroke) the rotor is at #1. If the problem persists after using a new gauge then maybe I'll look into picking up a intake/exhaust gasket. Can't find a leak anywhere using ether but that doesn't mean one doesn't exist. Jeff |

|

| Author: | Reed [ Thu Mar 19, 2009 12:39 pm ] |

| Post subject: | |

Your results are confusing, unless you have the curb idle screw turned in too far to keep the car running. The choke pulloff port should have full engine vacuum all the time. The distributor advance port should have no vacuum at idle but full vacuum when the throttle is opened. If you have the curb idle speed screw turned too far in it will provide a vacuum signal to the distributor advance port. However, this is wrong. At curb idle there should be absolutely no vacuum at the distributor advance port and full vacuum at the choke pulloff diaphragm. Something is set wrong on the carb to require you to turn the idle speed screw that far in. When I say the rotor is 180 degrees out, I mean that the rotor is pointing at the #1 plug tower when the #1 cylinder is at TDC on the exhaust stroke, not TDC on the compression stroke. The motor will run if the plug fires on the exhaust stroke, but not very well. To check this, pull your valve cover and rotate the motor over by hand. Watch for the intake valve on cylinder #1 to open and close. Keep turning the motor over and watch for the timing mark to get to TDC. The rotor should now be pointed at the #1 plug tower (pull the cap to check). If the rotor is pointed at the #6 plug tower, you need to pull the dist and reinstall it with the rotor 180 degree from where it is now. |

|

| Author: | SlantSixDan [ Thu Mar 19, 2009 1:08 pm ] |

| Post subject: | |

Quote: Good idea, I'll try a new one tonight. Hooking the gauge up where the vac. advance was

Ah. That won't work. You need a manifold vacuum source. The choke pull-off port is an okeh pick; a nipple installed in place of the threaded plug on the rearmost runner is the usual practice.Still waiting for (crucial) answer to the question about how well or poorly the engine runs. |

|

| Author: | JeffDavis [ Thu Mar 19, 2009 2:44 pm ] |

| Post subject: | |

SlantSixDan, Sorry for the delay. Motor seems to idle "OK" but has a definite stumble to it. Don't know how it runs yet because I also have a problem with the brakes that I have yet to resolve. Jeff |

|

| Author: | Reed [ Thu Mar 19, 2009 2:45 pm ] |

| Post subject: | |

Quote: Quote: Good idea, I'll try a new one tonight. Hooking the gauge up where the vac. advance was

Ah. That won't work. You need a manifold vacuum source. The choke pull-off port is an okeh pick; a nipple installed in place of the threaded plug on the rearmost runner is the usual practice.Still waiting for (crucial) answer to the question about how well or poorly the engine runs. |

|

| Author: | JeffDavis [ Thu Mar 19, 2009 3:29 pm ] |

| Post subject: | |

Reed. My choke is the well type with the bimetallic spring. I may have mispoke eariler when I referenced my choke pulloff port I was refering to what appears to be a diaphram used to smooth out the choke. Jeff |

|

| Author: | Reed [ Thu Mar 19, 2009 4:01 pm ] |

| Post subject: | |

Quote: Reed. My choke is the well type with the bimetallic spring. I may have mispoke eariler when I referenced my choke pulloff port I was refering to what appears to be a diaphram used to smooth out the choke.

All slant six chokes operate by both the bi-metallic spring in the pocket on the exhaust manifold AND the choke pulloff diaphragm on the carb. When the motor is cold, the spring in the exhaust manifold pushes the choke butterfly on the carb closed. As soon as the motor is started, the choke pulloff diaphragm sucks the choke butterfly ROUGHLY (not exactly) 1/4 inch open. As the bi-metallic spring in the exhaust manifold heats up, the choke butterfly is pulled the rest of the way open.Jeff The port for the choke pulloff diaphragm is one of possibly two or three ports on the carb that will give you a manifold vacuum signal. However, if you have an original 1964 Holley 1920 carb, I don't think there will be any other manifold vacuum ports on the carb. You should be hooking your vacuum gauge to the #6 intake manifold runner vacuum tree, as Dan suggested, or to the nipple for the choke pulloff hose. This diagram is for a later version of the Holley 1920, so it has extra nipples for emissions (that sounds somewhat dirty...), but yours will have the ones indicated:

|

|

| Author: | SlantSixDan [ Thu Mar 19, 2009 4:14 pm ] |

| Post subject: | |

Quote: All slant six chokes operate by both the bi-metallic spring in the pocket on the exhaust manifold AND the choke pulloff diaphragm on the carb

…except manual-choke trucks and vans, and pre-1964 automatic-choke setups which have a piston-and-cylinder internal pulloff rather than an external diaphragm.Carburetor operation and repair manuals (and some training movies) are posted here for free download. |

|

| Page 1 of 2 | All times are UTC-08:00 |

| Powered by phpBB® Forum Software © phpBB Limited https://www.phpbb.com/ |

|