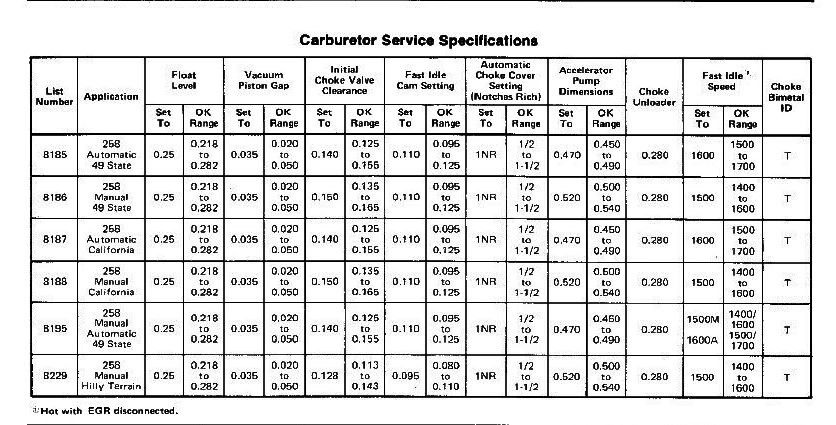

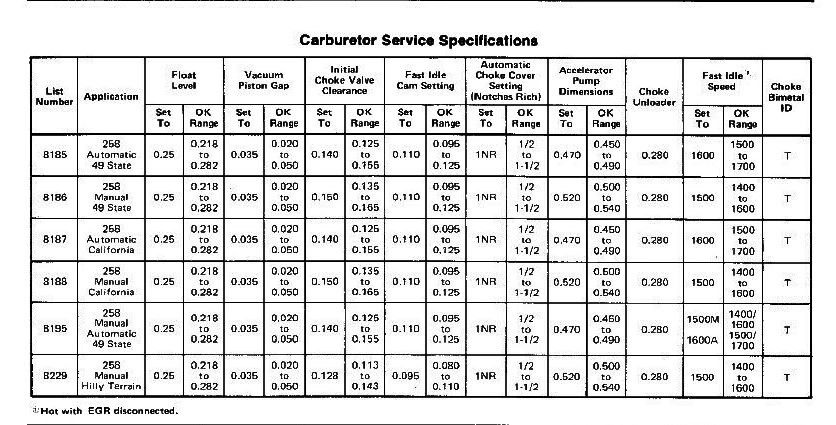

Also from amc jeep Note the piston gap set to .035 and after ok range for tuning .020 to .050

| Slant Six Forum https://slantsix.org/forum/ |

|

| Tin Top BBD 2BBL vacuum piston/metering rod relationship https://slantsix.org/forum/viewtopic.php?t=35294 |

Page 1 of 3 |

| Author: | ppsi [ Mon May 11, 2009 7:29 am ] |

| Post subject: | Tin Top BBD 2BBL vacuum piston/metering rod relationship |

I have a tin top BBD 2BBL and am curious about the adjustment for the vacuum (step up?) piston and the metering rods. The manual on this site state these should not be adjusted and I've not touched them however I'm wondering about what happens in doing so. There is a hole in the tin top where the small allen wrench would go to make an adjustment to these components so if I were to adjust the relationship between the metering rods and the piston does this enable one to enrich or lean out the high speen mixture. There are a lot o f posts about how people like the BBD because they are easy to adjust but I don't see any way to adjust the high speed mixture without touching the adjustment that is clearly stated as one that should not be touched. Thanks Howard |

|

| Author: | Rug_Trucker [ Mon May 11, 2009 8:20 am ] |

| Post subject: | |

I am thinking that Allen screw adjustment "don not touch!" was preset at the factory for emissions. The carb I am going to run on my Dart I disassembled that part before watching the BBD video. I luckily had another super six BBD and I set mine to the same height. There might be some richening available there. Also some in adjusting the little cam that lifts the rods. Have you checked for slop in the shaft yet? That will cause a lean condition. How do the plugs look? |

|

| Author: | matv91 [ Mon May 11, 2009 1:51 pm ] |

| Post subject: | |

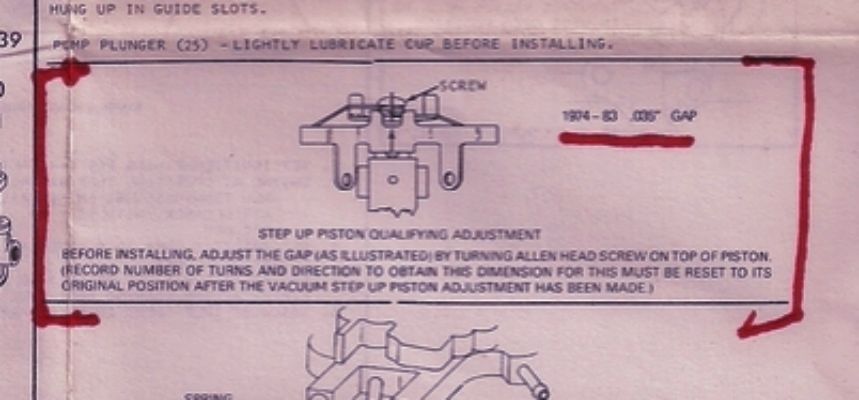

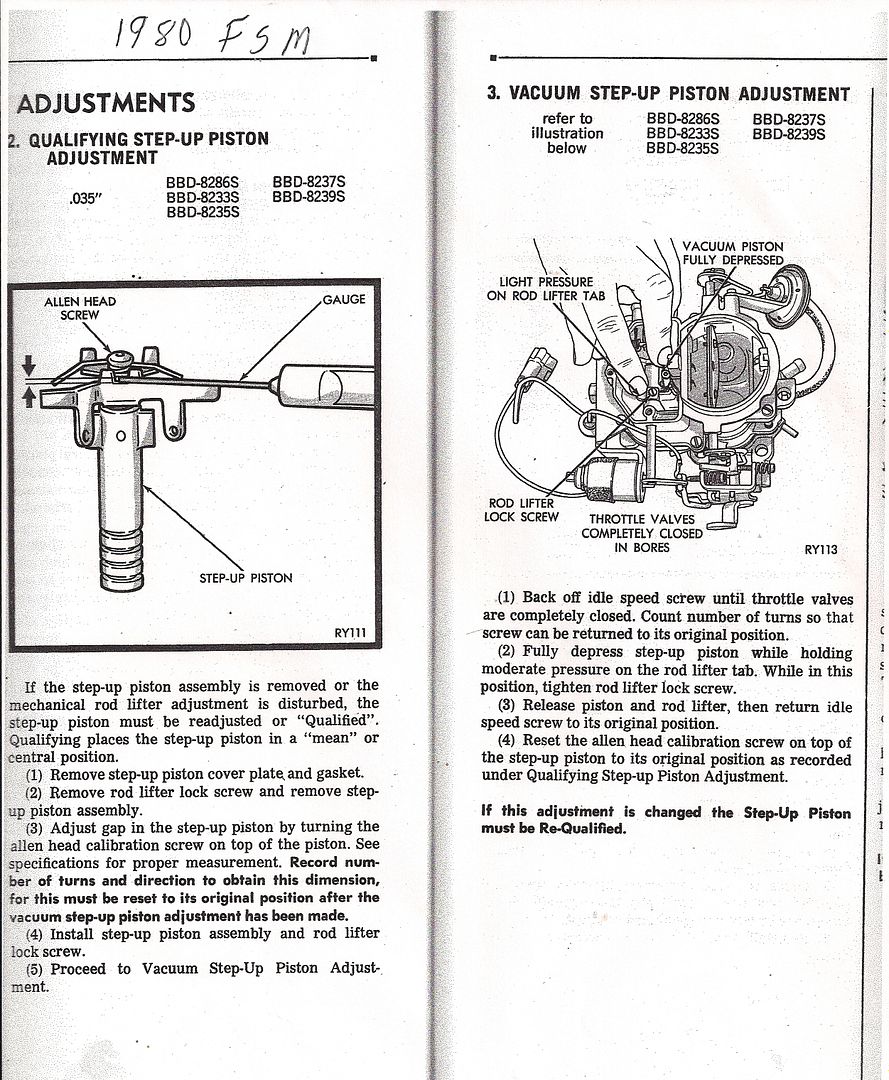

Back in the day there was much confusion and conflicting info on the vacuum step-up piston adjustment. For example 1974 (first year for tin top bbd) factory service manual says under vacuum step-up piston adjustment.If the piston is removed or the mechanical rod lifter adjustment is disturbed, the step-up piston must be readjusted or (Qualified). Qualifying places the step-up piston in a mean or central position. Adjust the gap in the step-up piston by turning the allen head screw on top of the piston to spec .030. The 1975 fsm says same thing only change is spec .035.The 1976 fsm says do not remove or adjust the allen screw and there is no gap spec listed. The 1977 fsm does not say any thing about the allen head screw at all.For 1978 were right back to Qualifying the step-up piston. The 78 fsm shows an adjustment the earlier manuals do not. Page 14-32 step 2 Qualifying step-up piston adjustment .035 If the step-up piston assembly is removed or the mechanical rod lifter adjustment is disturbed the step-up piston must be readjusted or Qualified. Qualifying places the step-up piston in a mean or central position. 1 Remove step-up piston cover plate. 2 remove rod lifter lock screw and remove step-up piston assembly. 3 Adjust gap in the step-up piston by turning the allen head calibration screw on top of the piston .See specifications for proper measurement.[.035] Record number of turns and direction to obtain this dimension for this must be reset to its orignal position after the vacuum step-up piston adjustment has been made.[not right after but after idle speed screw is reset to curb idle]. 4 Install step-up piston assembly and rod lifter screw. 5 Proceed to vacuum step-up piston adjustment. On the next page the last step in the vacuum piston adjustmentis .4 Reset the allen head calibration screw on top of the step-up piston to its original position as recorded under Qualifying step-up piston adjustment. This was the final word on this adjustment,all fsm after 78 had exact same instructions. Carter changed there instructions about 1980.The after market kits did not get this right till years later. |

|

| Author: | matv91 [ Mon May 11, 2009 3:44 pm ] |

| Post subject: | |

Now this is gues work, never seen any thing in print on this.But the whole idea for vacuum step-up piston adjustment is to get the metering arm phased to the throttle.Not to early,not to late and not too high or low.Sorta like adjusting throttle rod to automatic transmission.The way that metering rod arm is shaped has some thing to do with this.For example at lower throttle openings it does not move that piston very much and there is room for that piston to move.High vacuum pulls it down and low vacuum lets the spring push it up. As throttle approaches full throttle this freedom of movement is reduced,the piston is being forced up by the metering arm.As for setting the part throttle mixture thats where the allen head screw comes in.The metering rods are tapered. Turning the screw clockwise makes the fuel mixture richer.Raises the rod ,closes the gap. From .035 1 and one half turns will close up that gap. Turning the screw counterclockwise leans lowers the rods. Theres more room to lean out, about 1 1/2 turns from .035. This adjustment may or may not effect full throttle mixture. The power step of the metering rod is not tapered its a long straight section.This section acts as a guide pin,so that the rod goes back down in and does not come out of the jet.Once this power step is in the jet flow raising the metering rods will not change the mixture. Now this is not guess work.If by chance the rods get adjusted too high they can come out of the jets. This will jam the throttle open not allowing return to idle.With the tin cover off wing the throttle full open a few times.Make sure every things ok. |

|

| Author: | ppsi [ Mon May 11, 2009 4:57 pm ] |

| Post subject: | |

Yeah - I set mine as per the specs in the rebuild kit. The car runs very well (off idles that is) except I was wondering if this adjustment might afford me more fuel when running down the highway. Thanks |

|

| Author: | matv91 [ Mon May 11, 2009 8:38 pm ] |

| Post subject: | |

Turning allen head screw clockwise makes the fuel mixture richer. Turning counterclockwise makes the fuel mixture leaner. AMC uses bbd carbs also . On June 1 1978 Repair bulletin NO. 8-03 states some 1978 amc models equipped with 258 engine and bbd carburetor may accelerate unevenly. This condition may be the result of the BBD metering rods being set on the lean side of the mean specification.Service correction involves turning the metering rod adjustment screw clockwise 1 to 1-1/2 turns. Try this Keep notes Have fun. |

|

| Author: | Rug_Trucker [ Tue May 12, 2009 5:13 am ] |

| Post subject: | |

Thanks Matv91! |

|

| Author: | matv91 [ Sun Jun 22, 2014 4:22 pm ] |

| Post subject: | |

My guess is that the 1978 instructions should be used for all year carbs. Heres why, back in the day on almost new carbs 74 and 75 the piston gap was never at .030 or .035. This was very confusing,leading to questions like, set wrong from the factory or what? Most just left them alone but if the gap was too wide say .045 or more the metering rods would bottom in carb before set-up piston hit bottom of its bore.If the step-up piston is not at bottom this will reduce pressure on the spring,reducing its ability to push piston up under low vacuum conditions.Well thats a nice history lesson. At this late date original calibration long lost any way. |

|

| Author: | matv91 [ Sun Jun 22, 2014 4:30 pm ] |

| Post subject: | |

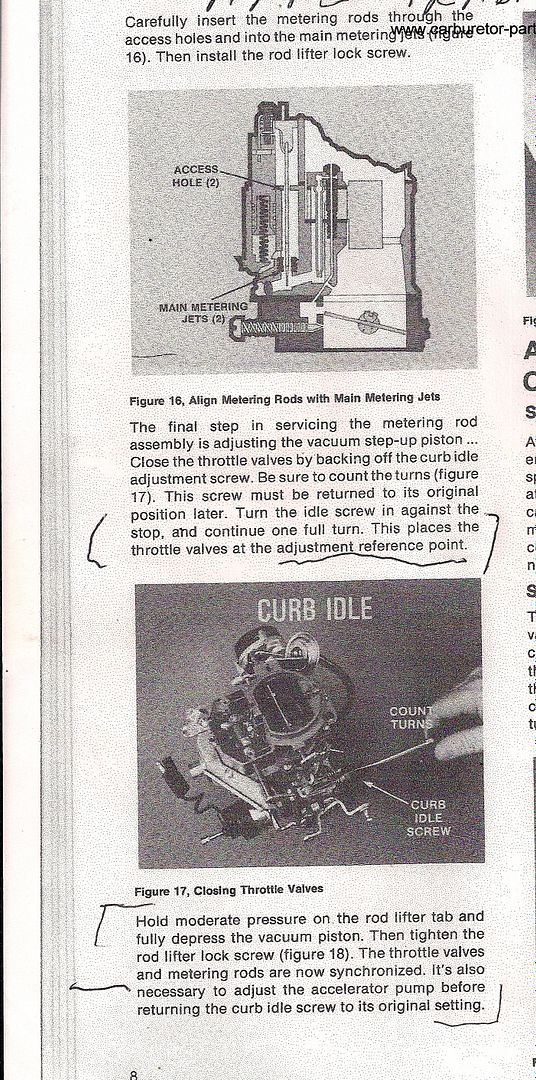

Found this from amc for there bbds http://c803310.r10.cf2.rackcdn.com/bbd_ ... manual.pdf Figure 17 shows metering rod adjustment |

|

| Author: | matv91 [ Sun Jun 22, 2014 4:36 pm ] |

| Post subject: | |

Also from amc jeep Note the piston gap set to .035 and after ok range for tuning .020 to .050

|

|

| Author: | matv91 [ Sat Jan 09, 2016 4:35 pm ] |

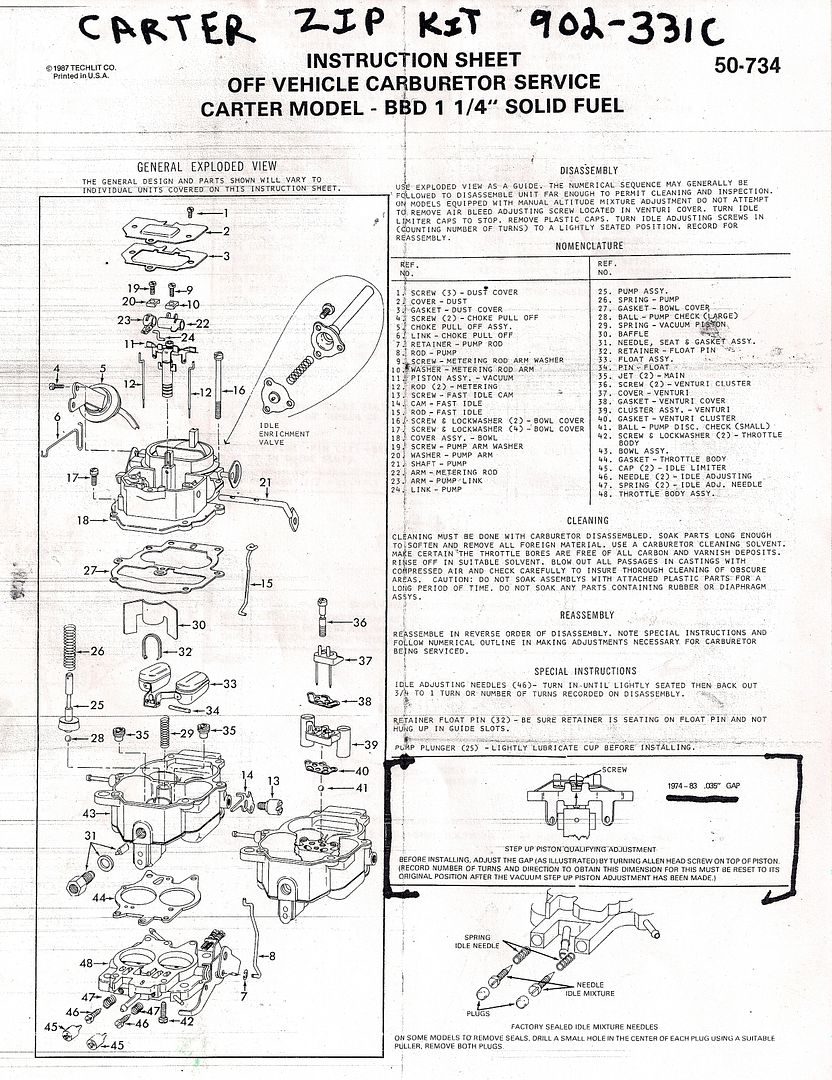

| Post subject: | Carter zip kit mid 80s |

|

|

| Author: | matv91 [ Sat Jan 09, 2016 4:39 pm ] |

| Post subject: | |

|

|

| Author: | matv91 [ Sat Jan 09, 2016 4:46 pm ] |

| Post subject: | 1980 fsm |

|

|

| Author: | matv91 [ Sat Jan 09, 2016 4:52 pm ] |

| Post subject: | Amc carter bbd book |

|

|

| Author: | matv91 [ Sat Jan 09, 2016 4:53 pm ] |

| Post subject: | Throttle sync |

|

|

| Page 1 of 3 | All times are UTC-08:00 |

| Powered by phpBB® Forum Software © phpBB Limited https://www.phpbb.com/ |

|