I am in the process (waiting on gaskets from Australia!) of installing a Weber DGEV on a friend's '74 Duster. I have done this conversion before to a Ford 200 CI inline with great success. Hopefully some of this info will be helpful to you.

My shopping list:

* Weber WK551 or WK551A DGEV Kit for Jeep (comes with manifold adapters to bolt directly to a super six manifold) - Ebay

* Weber 701-DGV Jet Kit for Jeep

* Super Six Manifold - Ebay

* Kickdown Cable Kit - Bouchillon Performance

* Throttle Bracket for 4 bbl - Bouchillon Performance

* Remflex RF6008 Manifold Gasket - Amazon.com

* Graphite Intake to Exhaust Gasket - gprsmopars.com

* Airtex E8016S Electric Fuel Pump - Autozone

* Big Block Chevy Fuel Pump Blockoff - Autozone

* EGR Blockoff - Ebay

* Sunpro CP8210 Air/Fuel Meter - Amazon.com

* Bosch 11027 Oxygen Sensor - Amazon.com

* Oxygen Sensor Bung - Ebay

* Weber A1000 Air Cleaner Adapter (allows use of the factory 1-bbl air cleaner, provided you have the hood clearance!)

* Holley 12-804 Fuel Pressure Regulator - Summit

* Mr Gasket 1561 Fuel Pressure Gauge - Summit

* 90 Degree Elbow and Bushing to screw gauge into second outlet of regulator - O'Reilly

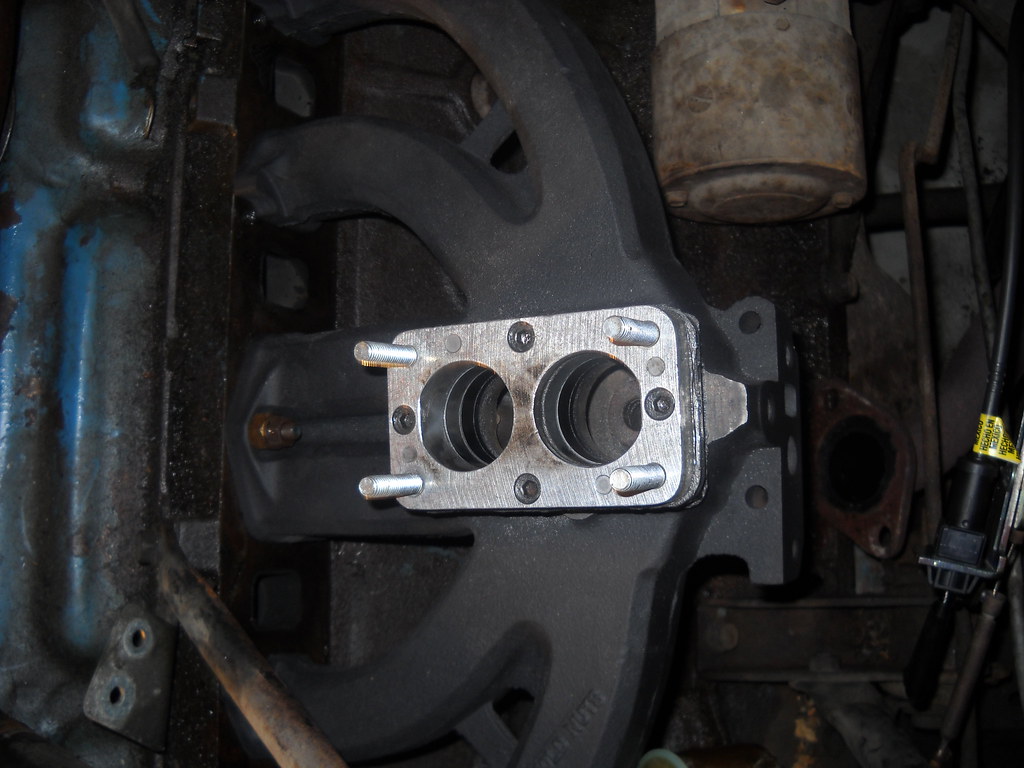

Using the adapter (Weber Part# 100.551) provided in the Jeep Kit, the DG series Weber will bolt directly to the Super Six manifold. While you can buy the carb and the adapter separately, I bought the kit because the carb in the kit comes jetted for an inline six already (potentially fewer jetting hassles). The Bouchillon Throttle Bracket comes as two parts that bolt together. I threw the part that bolted to the carb away, and made my own bracket out of a piece of 10ga steel (using the Weber Jeep linkage bracket and the Bouchillon carb bracket as templates). I will post pics of this bracket this weekend. Although unnecessary, I drilled a couple of holes in the Weber carb lever, and bolted the Bouchillon carb lever to it. This ensures that I get the correct throw for the kickdown (which Mr. Bouchillon stressed was very important). I will post pics of this, as well.

Aside from checking very carefully for vacuum leaks, I also recommend that you adjust your fuel pressure carefully. When I did this conversion on the Ford, I couldn't get it to run right at first. After trading the mechanical fuel pump for a good electric one (not the kind hanging in the "chrome" aisle at Autozone!) and putting a good regulator and gauge on it, the car purred. Fuel pressure should be about 2-2.5 PSI.

Use the Air/Fuel gauge to dial it in. The Air/Fuel system I use is very simple and rudimentary. It uses the cheapest 1-wire O2 sensor on the market, and the cheapest gauge on the market. It works well for me, but keep in mind that it will be slower to react that a wideband system.

Hope this helps!

|