I became a bit obsessed when I bought my compressor and planned the air lines in my garage.

Need to know a few things first - what sort of size/cfm are we dealing with, and what are it's intended uses? Will you ever paint or use a plasma cutter?

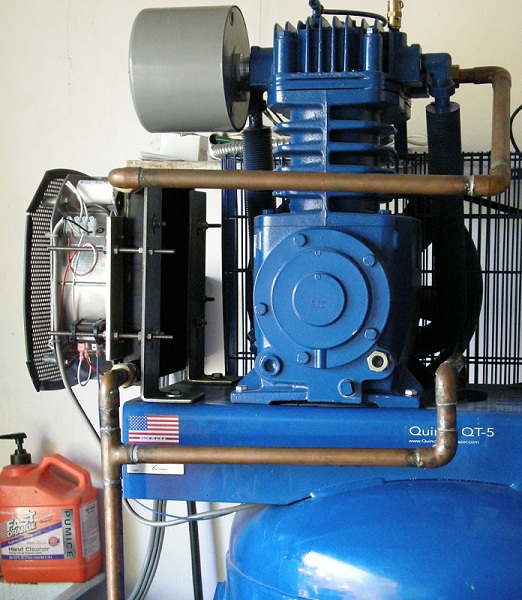

The first step in moisture removing is cooling the air. "Aftercoolers" (aka the cheap man's refrigerated dryer) will get a majority of the moisture out. They are more efficient when plumbed between the compressor and the tank as that is where the air is the hottest. They will work if you plumb it after the tank, but just not as efficient and still leaves more water sitting at the bottom of your compressor tank. I've included a pic of the way I did mine. A B&M transmission cooler with some crazy output (something like 1000cfm) fan on it. After the compressor runs for more then a few seconds the input line to the cooler is way too hot to touch. The output line is at ambient even after a long run. The only time the output line rises above ambient is when it gets close into the tripple digits, and then its barely noticeable. There are other ways to do poor man aftercoolers - google "franzonator" or "franz water seperator". Roger's method works as well however it takes more space and more solder points.

If you're just using general shop tools, a DA, die grinder, air ratchet/gun then this should suffice. You of course still should have a coarse air filter and regulator as well.

If you are going to paint, plasma, sandblast or anything else ultra sensitive to moisture and contaminants you will need to go further even if you have used a refrigerated dryer. After your coarse filter (which gets down to what, 20ish microns?) you'll need a coalescing filter that gets even smaller, sub 1 micron level. A popular cheap choice for these are the motorguard toilet-paper style filters. There are also others that use various media such as fiber or other synthetic media cartridges.

THEN comes your desiccant as the final stage before the regulator to absorb any last bit of moisture left. Using desiccant without a cooler or coarse/coalescing filter, while it works, is a no-no because you will be changing out desiccant or recharging it a lot more often. Desiccant isn't cheap, especially when you have to buy it in special cartridges for your unit.

Yes, coalescing and desiccant filters are meant more for point of use rather then "whole shop" type filters. If you only have one outlet, or you have more then one outlet but only use one at a time, you will be fine putting your stage 2/3 filters at the compressor.

The picture I have included is old. I have since modified the setup. The after cooler part is the same. The coarse filter is a milton unit. Then comes the motorguard, then comes 3 of the harbor freight desiccant units already linked to above running in parallel. 3 in parallel to reduce flow restriction and also slow down the air so it spends more time passing through the desiccant. The harbor freight units are quite economical especially with the 20% coupons, however be prepared to work to get them to seal (Rectorseal no. 5 is good stuff, just give it time to set) and clean the film of oil on the insides. I also drilled the inlet/outlet holes a bit bigger - the threads were 3/4 pipe but the holes behind them leading to the main tube were smaller. Then another coarse filter (not needed if the desiccant unit you choose has a fine internal screen or uses cartridge bags) after the desiccant to trap any pellets that got loose. I'll have to take another pic that shows everything. The setup looks like crap but works awsome.