| Slant Six Forum https://slantsix.org/forum/ |

|

| Oregon Cam Grind , no cam card in the box ??? https://slantsix.org/forum/viewtopic.php?t=40499 |

Page 1 of 2 |

| Author: | Damraider [ Fri Jun 04, 2010 10:31 pm ] |

| Post subject: | Oregon Cam Grind , no cam card in the box ??? |

Damn it !!! I received my cam today from UPS and there is no cam card . Too late to call now and they probably are not there tomorrow ( I will try them though) . It is a #819 grind , does anybody have the specs to this set-up ? I wanted to get this in the car this weekend .... |

|

| Author: | Joshie225 [ Fri Jun 04, 2010 10:55 pm ] |

| Post subject: | |

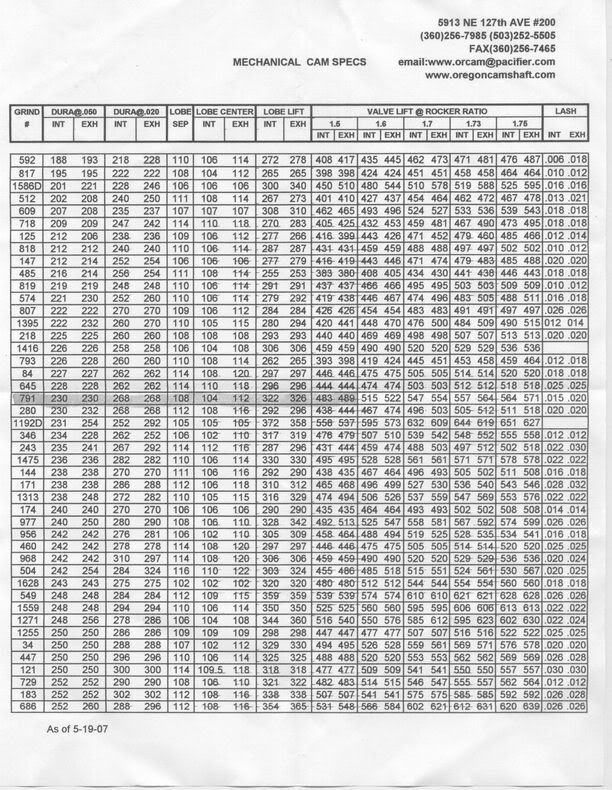

|

|

| Author: | Damraider [ Fri Jun 04, 2010 11:42 pm ] |

| Post subject: | |

Joshua Skinner , maybe I'm too much of a rookie but how do I degree the cam using the # posted on that sheet . Don't I need to know when the opening and closing of the valves happen ? Steve |

|

| Author: | emsvitil [ Sat Jun 05, 2010 12:04 am ] |

| Post subject: | |

Translated with desktop dyno... Duration I,E: 219 @ .050 Lobe seperation 110 Intake centerline 106 Exhaust centerline 114 IVO (BTDC): 3.5 IVC (ABDC): 35.5 EVO (BBDC) :43.5 EVC (ATDC) : -4.5 or 4.5 BTDC |

|

| Author: | Damraider [ Sat Jun 05, 2010 12:15 am ] |

| Post subject: | |

emsvitil , very cool !! This site has everything man , I mean everything !! Steve |

|

| Author: | Joshie225 [ Sat Jun 05, 2010 9:50 am ] |

| Post subject: | |

Quote: Joshua Skinner , maybe I'm too much of a rookie but how do I degree the cam using the # posted on that sheet . Don't I need to know when the opening and closing of the valves happen ?

If you know how degree a cam with the intake centerline method all the info needed is there. The intake centerline method isn't good for significantly asymmetrical lobes, but for these cams it's excellent. 106° intake centerline means the intake valve is designed to be at peak lift 106° after TDC on the intake stroke. I will find .050" down from peak intake lift on both the opening and closing sides of the intake lobe. I record the two crank positions and average the numbers to get the intake centerline.

Steve |

|

| Author: | Dart270 [ Sat Jun 05, 2010 10:22 am ] |

| Post subject: | |

I highly recommend degreeing the cam at 3-5 deg advanced (101-103 centerline) for best results on a 225. This comes from the result of many Slant Sixer's testing. Lou |

|

| Author: | Damraider [ Sat Jun 05, 2010 3:57 pm ] |

| Post subject: | |

Awesome ! Thanks guys , I will put it at 102 . I made a fixture on my CNC to machine a new hole in the cam gear once I determine how much it needs to be moved , that way I don't have to use a bushing. I will get some pics later on . Steve |

|

| Author: | Volare4life [ Sat Jun 05, 2010 5:09 pm ] |

| Post subject: | |

not to high jack, but I had the same problem, Josh if your ever in the jacksonville (fl) area, I owe ya a cold one, -Mike |

|

| Author: | Damraider [ Mon Jun 07, 2010 3:42 pm ] |

| Post subject: | |

Sunday was a busy one , installed the cam in the stock location and it degreed right at 106 like it was supposed to , then I went to my shop and made this little fixture . I mounted the stock gear to the fixture and machined a hole 188 degrees from stock ( 4 degrees in crank) . Went home and degreed the cam a couple more times to check and sure enough it went to 102 . Sometimes things work in your favour !!  Then I tried to mount the flywheel , Damn it !! , it was for the small register ... back to the shop for another fixture to open up the flywheel center hole.....   Thanks again guys for all the help !! Steve |

|

| Author: | Joshie225 [ Mon Jun 07, 2010 4:38 pm ] |

| Post subject: | |

I'm impressed and nice shop equipment! I think you mean you drilled the cam sprocket 182° from the original hole, but that's outstanding. You stamp the sprocket with the relative position for the 2nd hole? |

|

| Author: | Damraider [ Mon Jun 07, 2010 6:39 pm ] |

| Post subject: | |

Quote: I think you mean you drilled the cam sprocket 182° from the original hole No , 188 degrees (8 degrees past 180 in the counterclockwise direction , or 172 in the other direction )from the original hole so that the timing mark would still line up but it would be on the top of the gear instead of the bottom . |

|

| Author: | Joshie225 [ Mon Jun 07, 2010 7:25 pm ] |

| Post subject: | |

Right, putting the hole 180° off would accomplish nothing. Moving the hole 188° would be 8° at the cam and 16° at the crank. |

|

| Author: | Damraider [ Mon Jun 07, 2010 8:46 pm ] |

| Post subject: | |

Quote: would be 8° at the cam and 16° at the crank.

Nope , crank rotates twice as far as the cam , 8 cam is 4 crank . 360 on the crank is 180 on the cam .

|

|

| Author: | ceej [ Mon Jun 07, 2010 8:54 pm ] |

| Post subject: | |

Look at your numbers.... CJ |

|

| Page 1 of 2 | All times are UTC-08:00 |

| Powered by phpBB® Forum Software © phpBB Limited https://www.phpbb.com/ |

|