Sounds like a fun swap.

Not really sure if anyone here has done it, but there are some weird swaps that have been done.

| Slant Six Forum https://slantsix.org/forum/ |

|

| Slant 6 Swap Into 48 Chrysler https://slantsix.org/forum/viewtopic.php?t=43368 |

Page 1 of 1 |

| Author: | carman35 [ Mon Jan 24, 2011 4:01 pm ] |

| Post subject: | Slant 6 Swap Into 48 Chrysler |

I have seen comments in various places on the web, mainly saying DON'T DO IT, but I like a challenge. I bought a 225 with TorqueFlite about 6 years ago. I had 2 slants during the '70s and liked them, and I know they can handle this 2-ton battleship, at the speeds that I need. I once owned a 1964 Class A Cortez motorhome powered by a 225, and I drove that thing, fully loaded, up and down mountains, and still got 12.5 mpg!. I have the engine & trans suspended in position, and the only problems involve the steering box and linkage. (I did cut a small doghouse into the firewall, but that was mainly extra clearance, for a better looking installation.) When the steering is turned hard left, the pitman arm and tie rod end hit the oil pan. My pan is a center sump version, but internet photos indicate that a rear sump (truck?) pan should clear. Also, there is not a lot of space between the stock exhaust flange and the steering box, so that will require a fairly sharp bend, though not extreme. Of course, I will need to fab motor mount brackets and a rear cross-member for the trans mount. Has anyone here already mastered this swap? I have done several odd-balls in my life, but there is no sense in wasting somebody else's great "wheel invention". |

|

| Author: | slantzilla [ Mon Jan 24, 2011 6:12 pm ] |

| Post subject: | |

Sounds like a fun swap. Not really sure if anyone here has done it, but there are some weird swaps that have been done. |

|

| Author: | JR [ Mon Jan 24, 2011 8:27 pm ] |

| Post subject: | |

Just ignore what the idiots over on the HAMB told you... I did it in a 48 chevy but it has a Mustang II kit in it. You might try a front sump truck pan as well it might work better for you depending on where your crossmember is. Just remember, it is only metal and you can do anything to anything with a grinder and welder! Here is the whole album.... http://s88.photobucket.com/albums/k199/ ... 8%20chevy/

|

|

| Author: | carman35 [ Mon Jan 24, 2011 9:00 pm ] |

| Post subject: | |

WOW! Excellent job. Very thorough. More than I want to do for this car, though. I will try to just work around the corners. |

|

| Author: | Wesola78 [ Tue Jan 25, 2011 8:13 am ] |

| Post subject: | |

Cool project! |

|

| Author: | GTS225 [ Tue Jan 25, 2011 11:23 am ] |

| Post subject: | |

Hey, Carman........before you get too deep into fabbing mounts, might I suggest you double check your underhood and trans tunnel clearance? You might be able to gain a couple inches by raising the engine a touch. That could give you a bit more wiggle room between the exhaust and steering box. I might suggest you get yourself a set of spool engine brackets. You can then easily fab a set of "ears" to weld or bolt to the frame rails to match up to the engine bracket bushings. How about the possibility of "clocking" the pitman arm a few degrees on the pitman shaft? ('course, if it's got an index in the splines, that'll kill that idea.) That may take care of your pan interference problem. You then might be able to make up the difference with adjustments in tie rod length. FWIW....I have an '81 Mitsubishi-built Dodge Challenger with a slant in the front, that I built, with some fabrication supervision from a good and more experienced friend. Roger |

|

| Author: | olafla [ Tue Jan 25, 2011 5:51 pm ] |

| Post subject: | |

Hi carman35, you might get in contact with our member '56 dodge', he has this very nice 56 truck with a SL6 in it. I know it is not the same, but he may have some useful info. Olaf |

|

| Author: | Tim Keith [ Tue Jan 25, 2011 6:18 pm ] |

| Post subject: | |

The 225 can work in the '48 Chrysler, some of which had a straight 8. This is the 46-48 Dodge-Plymouth site. They can tell you about the Chryslers. http://www.merc583.addr.com/mopar/index.html A popular Dodge/Plymouth mod is a Chevy Cavalier steering rack with a low cost mount from Fatman. Steering box clearance is the major hurdle. |

|

| Author: | olafla [ Tue Jan 25, 2011 6:39 pm ] |

| Post subject: | |

Another popular mod to get modern steering and brakes, is the complete front subframe from a pre-92 Dakota; slides right into your frame rails! Olaf. |

|

| Author: | JR [ Tue Jan 25, 2011 7:21 pm ] |

| Post subject: | |

Quote: Hey, Carman........before you get too deep into fabbing mounts, might I suggest you double check your underhood and trans tunnel clearance? You might be able to gain a couple inches by raising the engine a touch. That could give you a bit more wiggle room between the exhaust and steering box. I might suggest you get yourself a set of spool engine brackets. You can then easily fab a set of "ears" to weld or bolt to the frame rails to match up to the engine bracket bushings.

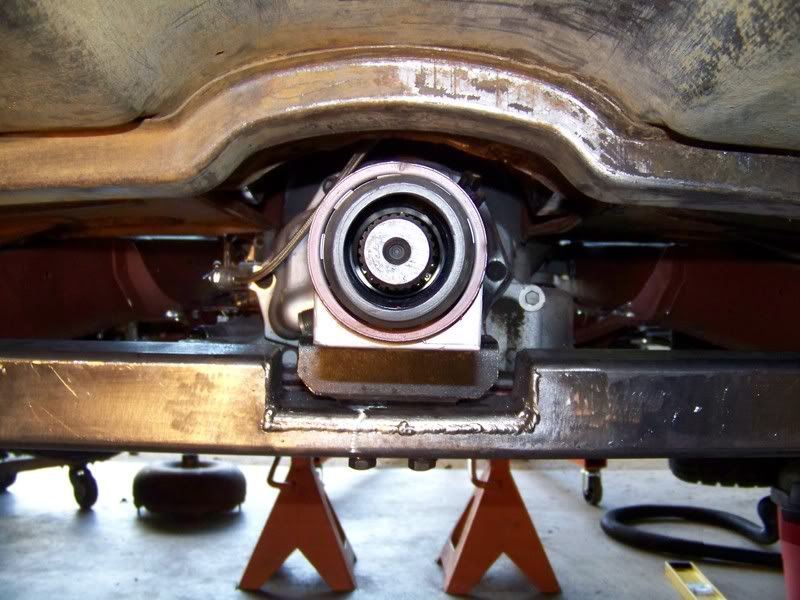

That is exactly what I did, easy as pie! I do wish that I raised the engine about an inch but as it is I still have enough room to drop the pan, pick up tube, oil pump and crank with the engine in the car. Make sure that when you are mocking everything up you maintain your pinion angles and try to keep the it level side to side.The 48 is still in project mode and now I have to re-do the fire wall to make room for this...

|

|

| Author: | carman35 [ Thu Jan 27, 2011 10:53 am ] |

| Post subject: | |

I guess I have to apologize to you guyz for not responding quickly, but I am new to this board and apparently didn't understand just how it works. The system automates a notice to my email when there are responses posted, but for some reasson, I have been receiving notices for another string (or two), so have not seen the recent posts here. I have been answering to those other strings. Thank you all for your help and consideration, and I will try to follow up on them. I just discovered this situation at a friend's home, when I used a different method to access this forum, so I will wait until I get back home to read everything. Thanks, again! Carman35 |

|

| Author: | carman35 [ Thu Jan 27, 2011 10:29 pm ] |

| Post subject: | |

Roger: Thank you for your suggestions. My engine/trans are currently supported at the front by my cherry picker and at the rear by a trans platform jack. Both allow very small changes, while maintaining stability. When I started fitting the drivetrain, I found a good spot that allowed just about everything to work out, but the darn front of the engine was about 4-inches too high. After doing research on oil pans and the unique problems of oil foaming and misting with slanted block engines, I could see that having a high oil level in the rear of the pan was a very bad idea. I proceeded to spend a full day, moving that engine/trans up, down and all around, but with the crankshaft level and the tailshaft as close to the tunnel as I dared to go, I could not solve everything. The pulley was fine; there was room for support brackets on both sides in front; there was ample clearance and access to the distributor and two pumps, and the new crossmember was a snap. In fact, if I had a rear sump pan, the stock steering gear would work without a hitch. I did make a minor doghouse in the firewall, but that was done more for appearance than necessity, as the valve cover was about to touch, and I didn't want it to look too tightly confined. If I can locate a rear sump pan and pickup tube, the only remaining big problem has to do with the exhaust. more... |

|

| Author: | carman35 [ Thu Jan 27, 2011 10:41 pm ] |

| Post subject: | |

Continued: The exhaust flange dumps straight into the top of the steering box, and it would take a pretty tight bend for the pipe to clear it. You must understand that I am doing this as much for the challenge as anything else, so I am also trying my best to use standard parts, as much as possible, so that others might become encouraged to follow my method, if it turns out to be a good swap. You can't avoid a long list of other needs, including fabbing the engine brackets, cooling lines, X-member, shifter linkage, wiring, etc., but I don't want to introduce a rack or Mustang II front end. Those are just my basic ground rules for this "simple" swap. As to the exhaust, I am not inclined to use tube headers, and I am starting to think out a solution that would allow the manifold to exit pointing slightly to the rear, as well as downward. About 30 years ago, I dropped a Chevy into my V-12 Jag XK-E. I sawed off the flange from a regular Corvette "Ram Horn" manifold and inserted a length of steel exhaust tubing, which I brazed together. That car went over 200K miles without a failure, so I am now thinking about doing a similar mod to my stock SL6 manifold, inserting a pre-bent steel pipe. I haven't settled on that yet, but I'm looking at that now. Carman35 |

|

| Author: | carman35 [ Thu Jan 27, 2011 10:53 pm ] |

| Post subject: | |

Tim: Thank you, too!! I have owned a few 1946-48 Chryslers and have completed frame-off restorations. I have restored both 6- and straight 8-cylinder models. The 8s have a 6-inch longer frame (and hood) than the 6s. I suspect that would easily turn this swap into simplicity itself, due to all that extra room. The entire frame stretch is ahead of the firewall, so that the car bodies are identical, but the front clips of the two versions share no sheetmetal parts. My project car is a C38 Windsor, 6-cylinder car. I know it would have been easier to simply drop a shorter V8 into the engine compartment, but I thought that the updated and indestructible SL6 was the appropriate replacement for the venerable flatty 6. Plus, I wouldn't find myself parked next to another one at the local McDonald's. So, that is my quest. Carman35 |

|

| Author: | carman35 [ Thu Jan 27, 2011 10:59 pm ] |

| Post subject: | |

JR: Your car is a real work of art and ingenuity. I love it! I hope I get to see the finished product, some day. I really appreciate talented guys who march to a different drummer, and don't take "No", or "Can't be done", for an answer. That intake is the last straw!!! Carman35 |

|

| Page 1 of 1 | All times are UTC-08:00 |

| Powered by phpBB® Forum Software © phpBB Limited https://www.phpbb.com/ |

|