okay, i am in the middle of degreeing my cam, and i have ran into a bump i n the road.

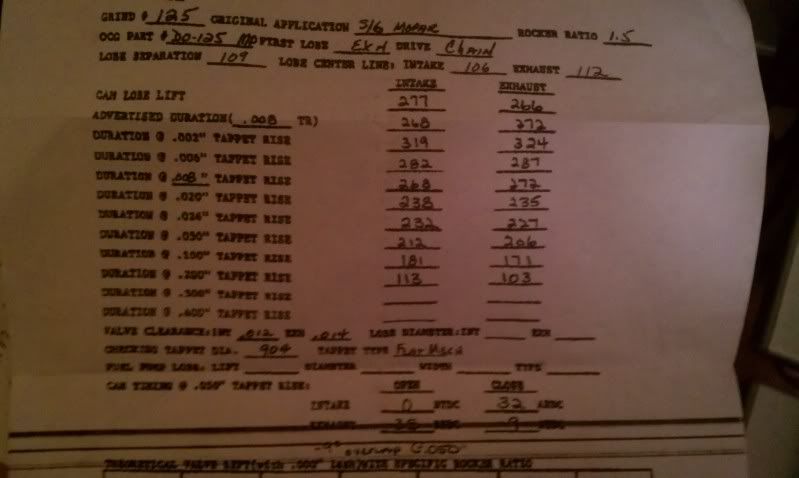

oregon cam grid #125

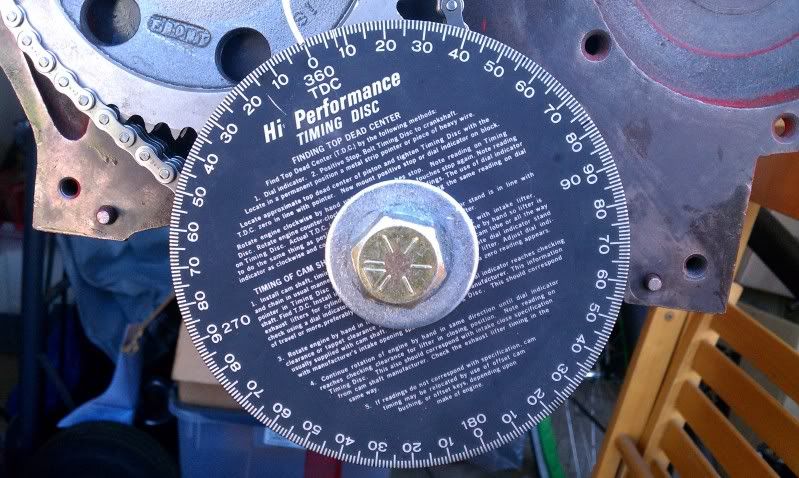

first i set the motor to TDC with my depth height gauge

then i turned the motor over until highest point on cam lobe, and set gauge to 0

this is where the degree wheel sits at max lift, about 78

turned motor over counter clockwise till guage read .050, degree wheel reads 32

roll motor back over clockwise, past max lift, and back down to .050. degree wheel reads 57

cam card reads, that the intake should open at 0 BTDC, and close at 32 ABDC. now i got 1 number right, but what the hell happened with the other? help would greatly be appreciated.

here is the "cam card"