Quote:

its now time for me to finish up the top end. i cleaned up the rockers and shaft, now its time to grease it all up and put them together. i noticed that one of my bolts is extra long (closest hole to the back in the head, shows to have no threads up top, and deeper.) curious why that is.

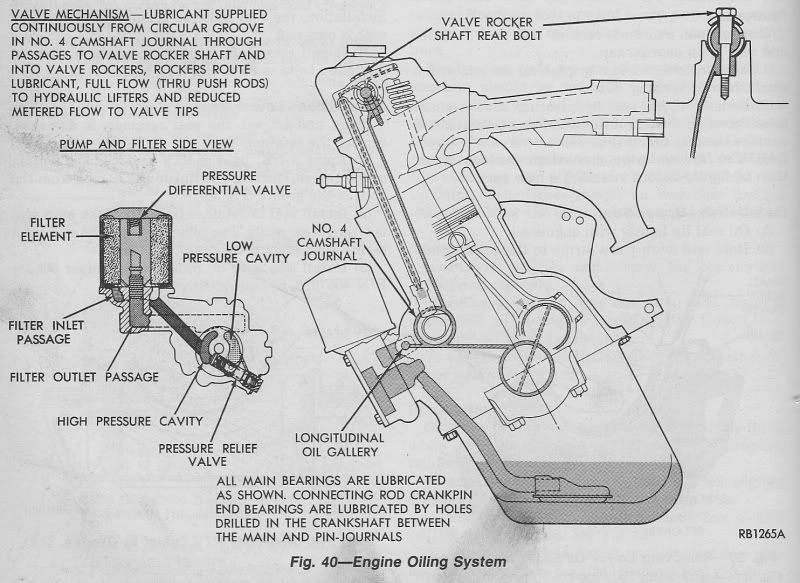

Because the slant six uses the rearmost rocker shaft bolt hole to feed pressurized oil up into the rocker arm shaft and out through the holes in the shaft to the rocker arms.This diagram is for a hydraulic lifter motor, so just ignore the bit about the oil going down the push rods. On a non-hydraulic lifter motor the oil dribbles out the end of the rocker arms and down into the lifter valley and then back into the oil pan from whence it came.

Quote:

also im wondering which direction the shaft goes. i noticed there seem to be small oil holes on one side, wondering if that shoots towards the "drool toobs" or valve springs. i noticed inside the rockers, the oiling slot is towards the springs i believe. the way it seemed to be set up originally was towards the tubes.

At the end of the rocker arm shaft, there is a little flat. The flat needs to go to the front of the engine facing up. You can see it in this picture:

Quote:

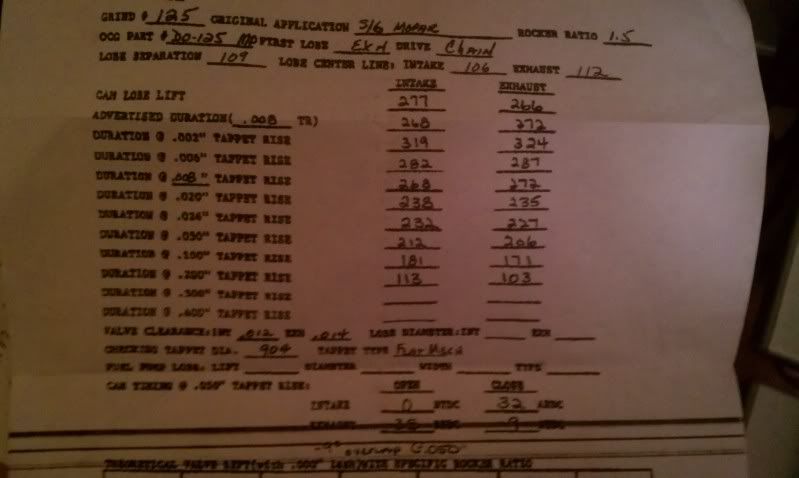

also from the oregon cam spec card, it says to set intake- .012 exhaust .014.

is this the cold number, or hot?

what should i set the valve adjustment to for initial run.

This is beyond my ken.is this the cold number, or hot?

what should i set the valve adjustment to for initial run.

Quote:

oh also, what is the torque for the rocker shaft bolts. thanks

25 foot poundsQuote:

and if there is anything else you think i need, please let me know

Factory service manuals are very helpful.

[/img]

[/img]