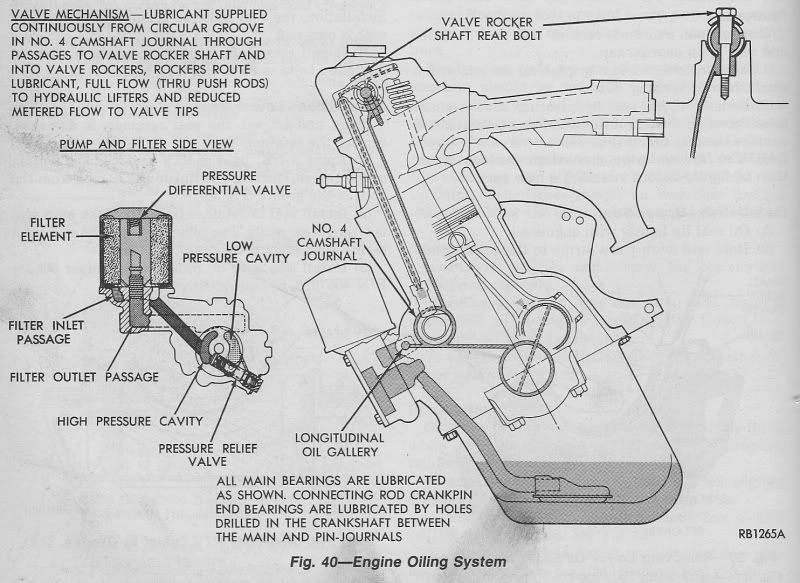

Here is the oiling system on a hydraulic slant six:

First pull the rocker arm assembly and look down the hole for the rearmost rocker arm shaft mount. The oil feed hole for the valve train is in the hole for the rocker arm shaft bolt. You may need to get a pipe cleaner and clean it out.

Second, make sure the rocker arm shaft and rocker arms are not full of caked up sludge. You may need to take them to a machine shop and get them hot tanked. The oil should flow fairly steadily from the tips of the rocker arms above the valve stems wen the motor is running.

Is this an all stock hydraulic motor or has there been mixing and matching of any components?