I bought a rebuilt head from Doc and was installing my exhaust and intake manifolds tonight.

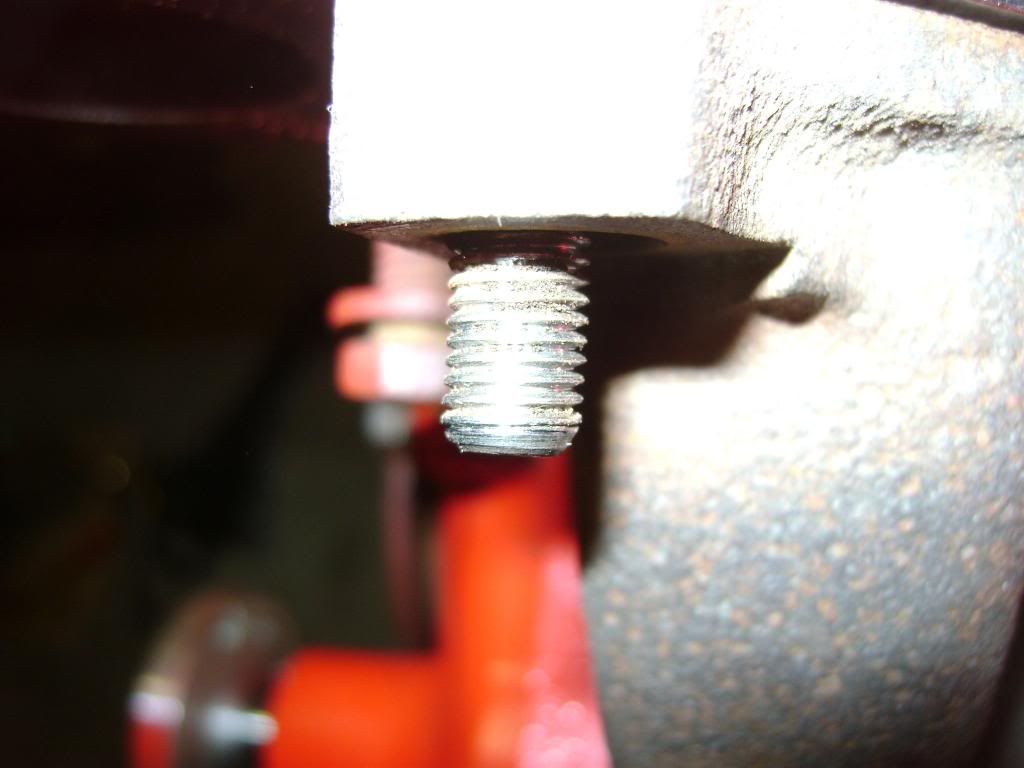

Kept trying to install the nut/brass ring combo on the first exhaust manifold stud on top, next to the water elbow outlet. The flex nut just doesn't want to thread on.

What's a good way to fix the situation without having to take everything apart and remove/replace the stud?

I think it's the end, which looks a mite 'unthreaded', and is causing the flex nut not to catch. Pressing on the nut as I turn doesn't seem to do any good. Any advice about what to do would be wlecomed, thanks.