I made a tool that expands exerting force on ball joint stud, and a good stout tap with a hammer on the knuckle will separate the two. A few washers are need for shims and flipping retaining nut provides flat spot to mount tool.

| Slant Six Forum https://slantsix.org/forum/ |

|

| Now for the front end https://slantsix.org/forum/viewtopic.php?t=54116 |

Page 1 of 1 |

| Author: | Dltarnnr [ Sat Dec 21, 2013 4:29 pm ] |

| Post subject: | Now for the front end |

Just wanted to know what im getting into .No shop has called back so guess I will replace upper and lower ball joints myself.Its been a longtime but from what I remember just need a pickle fork.Any thoughts? Its a 63 dodge model 440.John |

|

| Author: | 65 dartman [ Sat Dec 21, 2013 6:24 pm ] |

| Post subject: | |

No pickle fork - use a ball joint socket. A bodies up through 72 used the small socket, B Bodies from 62 through 72 and most A Bodies 73-76 use the next size larger - don't remember the exact size. I'm sure someone will chime in on the size. |

|

| Author: | '67 Dart 270 [ Sat Dec 21, 2013 6:29 pm ] |

| Post subject: | 73-76 size |

This is the 73-76 size: http://www.summitracing.com/parts/sxt-10213/overview/ |

|

| Author: | Dltarnnr [ Sat Dec 21, 2013 9:14 pm ] |

| Post subject: | |

Thanks guys, it was back in my pontiac days that I did one.Havent pulled the maual out yet but so far it sounds easier than pressing in. |

|

| Author: | DusterIdiot [ Sun Dec 22, 2013 7:53 am ] |

| Post subject: | Umm... |

Quote: No pickle fork - use a ball joint socket.

He will need both as he has to separate the balljoint from the spindle then he can attack the balljoint with the socket...the other method is to either fabricate or buy (expensive) a tool that wrenches into place between the LBJ and UBJ and pushes the studs out of the spindle. The problem with the pickle fork is it has a tendency to rip the grease balloon.-D.Idiot |

|

| Author: | slantzilla [ Sun Dec 22, 2013 9:07 am ] |

| Post subject: | |

You can also just back the nut off some, use a pry bar to put some downward pressure on the spindle, and whack the side of the spindle with a hammer. It will pop the ball joint loose and not kill you. Bottom one can be split the same way. |

|

| Author: | Dltarnnr [ Sun Dec 22, 2013 5:53 pm ] |

| Post subject: | |

Well got the lower ball joint off had to take A arm off and still cant get the upper loose? Its the left side did they reverse the threads Guess I will let it soak overnight and try again using pipe wrench cause nobody has socket. |

|

| Author: | 2 Darts [ Wed Jan 01, 2014 11:14 pm ] |

| Post subject: | |

The UBJ is a bear to get off. Recommend that the arm be installed in the car and the appropriate ball joint socket used. I also use a very long cheater bar on the breaker bar handle to get enough torque to get the UBJ loose. By long, I'm talking 4-6 feet. Do not use a ratchet handle with the long breaker bar! Ask me how I know and why I like lifetime tool warranties. If you have a Haynes manual, pay no attention to what it says about the ball joint being pressed into the arm. I don't know where that BS came from, but it's for sure they did not change one out on a 61-76 A-body when they prepared their manual. |

|

| Author: | Pierre [ Thu Jan 02, 2014 12:08 am ] |

| Post subject: | |

No left hand threads, all right hand. Did you separate the spindle from the upper joint already? Your doing it with a pipe wrench? Ick. That's begging for busted knuckles. Even if you manage to get it out, how are you going to torque the new one on without a socket? These things are spec'd at over 100 ft-lb torque. |

|

| Author: | wjajr [ Sat Jan 04, 2014 3:21 pm ] |

| Post subject: | |

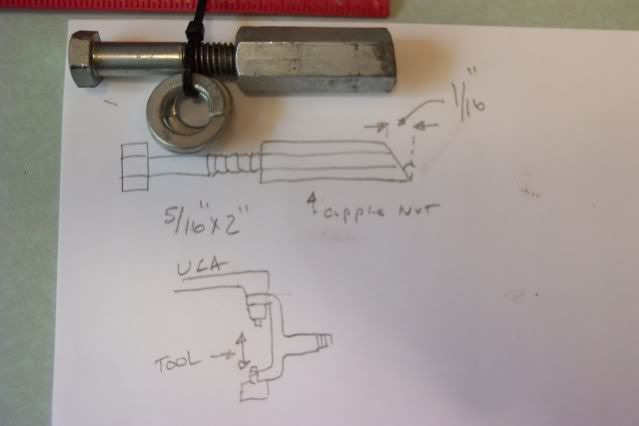

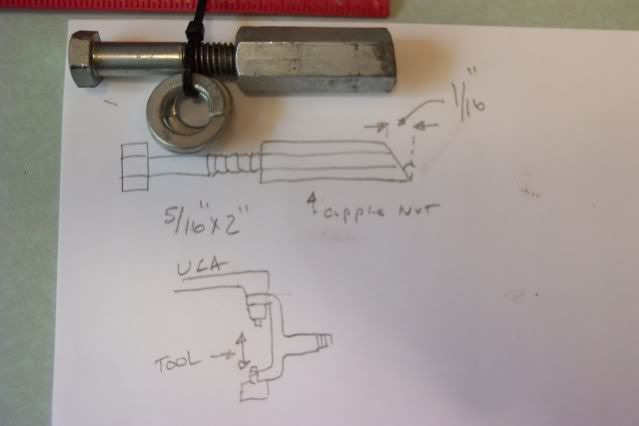

I made a tool that expands exerting force on ball joint stud, and a good stout tap with a hammer on the knuckle will separate the two. A few washers are need for shims and flipping retaining nut provides flat spot to mount tool.

|

|

| Author: | DusterIdiot [ Sat Jan 04, 2014 6:47 pm ] |

| Post subject: | Yep... |

The tool wjajr has is the tool shown in the Field Service Manual and works great except in the cruddiest rusty stubborn junkyard finds. Last time I did my front end I believe I ended up using a 3/4" drive torque wrench at 150 ft/lbs to get the UBJ seated correctly...luckily I am tall and could wedge my legs behind the bumper or on a subframe rail to get more leverage... -D.Idiot |

|

| Author: | 65 dartman [ Sat Jan 04, 2014 6:51 pm ] |

| Post subject: | |

Quote: The UBJ is a bear to get off. Recommend that the arm be installed in the car and the appropriate ball joint socket used.

I have a Craftsman HD 1/2" drive impact gun and it's never failed to unscew the upper ball joint. Yes I leave the UCA attached to the car.

|

|

| Author: | Dltarnnr [ Wed Jan 08, 2014 9:16 am ] |

| Post subject: | |

Thanks guys I bought a socket which should do the job. |

|

| Author: | '67 Dart 270 [ Wed Jan 08, 2014 11:23 am ] |

| Post subject: | ball joint separator... |

IF you don't want to use a pickle fork, as Rob suggests, there are separators. Harbor Freight has one for $20, See: http://www.harborfreight.com/3-4-quarte ... 99849.html I don't know if it's any good, but it appears pretty sturdy. BG |

|

| Author: | Dltarnnr [ Thu Jan 09, 2014 9:54 pm ] |

| Post subject: | |

All the info has helped thanks again now its off to get alignment |

|

| Page 1 of 1 | All times are UTC-08:00 |

| Powered by phpBB® Forum Software © phpBB Limited https://www.phpbb.com/ |

|