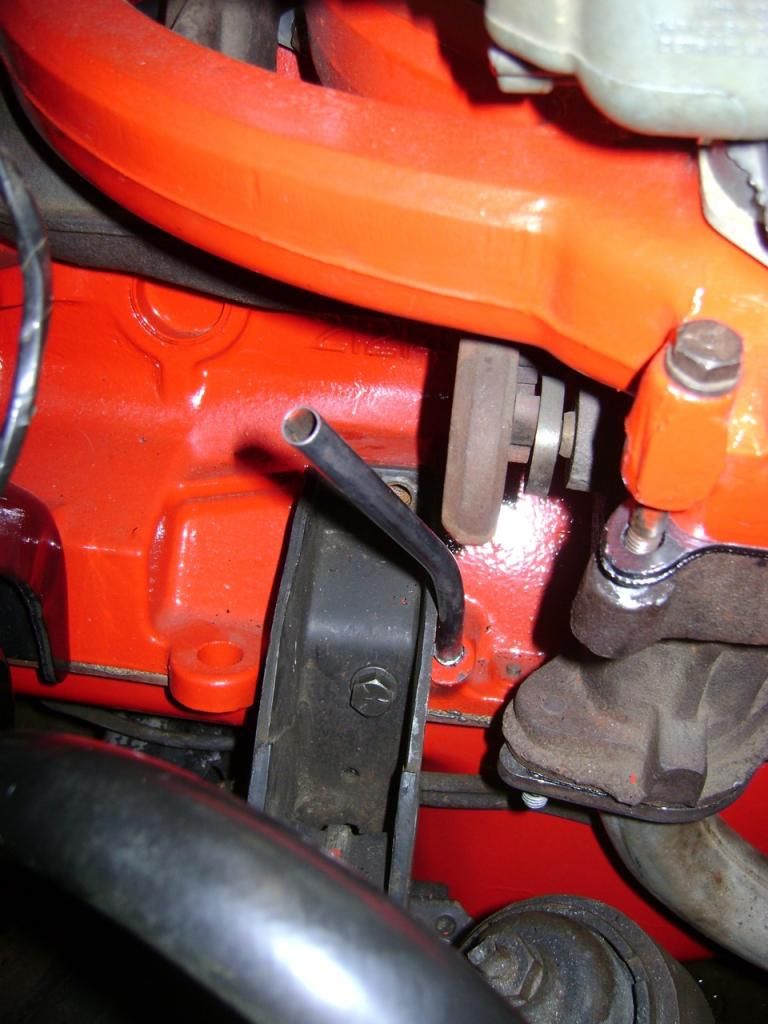

Quote: Support the engine and remove the motor mount to give you a little more clearance. Use a box wrench to slip over the tube and rest against the flange. That will give you a surface to strike but the force of the blow will be distributed over a wider area to avoid further damage to the tube.

Alternatively, Lowes has some steel bushings in their hardware area; find one that will just slip over the tube. It will have to be a little loose to go past the bend and it would be best to get the shortest one available or even shave off a ring with a hacksaw. ^^ This... remove the mount temporarily. And then use one of the many good suggestions to put force against the tube flange.

Hint if you don't have a hoist handy: I have a super cheapo tiny bottle jack that can be set on the K member near the front left with a block of 2x4 under one side that tilts the jack at the correct angle to point it right up at the forward left corner of the oil pan flange on the engine. A piece of 1x2 on the top of the bottle jack protects the pan flange, and with a few pumps, the engine is tilted up a bit and the mount can be removed. Takes 2-3 minutes to set up. (If you do this, you would be wise put some other pieces of wood on the K member as back up support for the bottle jack while you pound on this tube, juuust in case the jack slips.) And, BTW, this is for a '62 Dart (B-body) so I might have more room to do this. And just be careful with your hands anytime yo use a shortcut lift method like this.

|