Alright, I've been playing around with this for over a year and I think I've finally got to a point of kicking this off. I have a local machinist who is well respected and tired of doing SBC's day in and out.

The assumption is that removing a blockage of 1/8" from the middle of the port is similar to opening to port walls on each side by an 1/8", due to the boundary layer. Bowl and roof work will still be done, but hopefully to a lesser extent than what a "serious" port job requires to achieve similar flow.

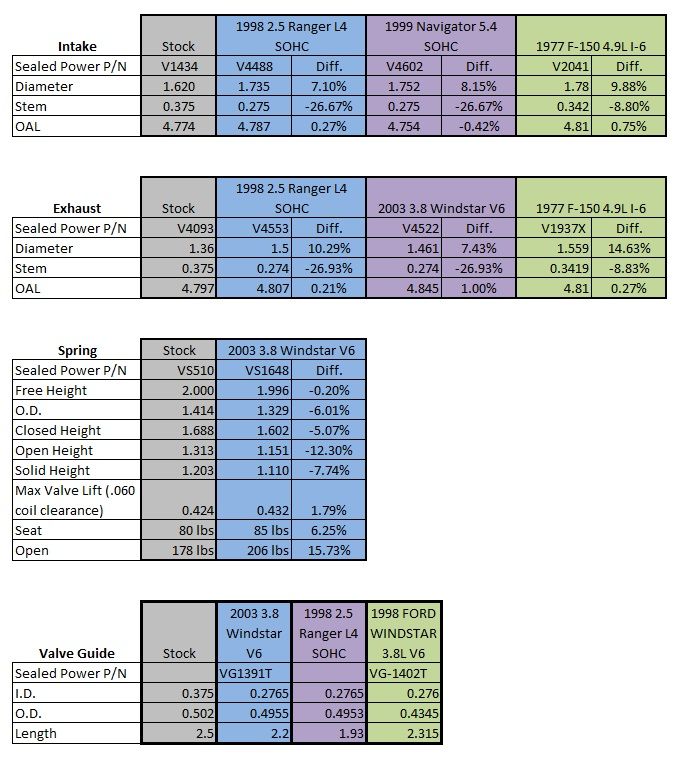

I've made a comparison of stock sizing against what I consider the "front runners".

Right now I'm leaning towards the Navigator intake and Ranger exhaust valves.

Spring options are limited, but I'm eventually going turbo, so I don't think limited lift will be an issue.

Guides will likely be the 1998 Windstars.

In theory, the head will go under the knife next week.

The machinist has a SuperFlow and plans to flow it "as cut" before we start doing any port work.

I'll keep you posted...