Greetings everyone! This is my very first post to this forum. I have been lurkin here for over a decade, but finally decided to share my very own project.

First of all, this is my first engine project with a boost factor. I have a 1961 Dodge Pioneer 2D HT, which left the factory equipped with 225 slant six engine. I have owned this car for few years now. This is not my first or last slant six car though. But the most fun yet, it has been.

So, why supercharge the slant six if you could get a lot of fun fast and easy with a big block?

I do it because it's different and way more entertaining. And it's different here, in Finland where I live. Old american cars are more popular here than ever. But Valiants, Dusters, Darts and Aspens did conquer the hearts of FIN when they were new. And those cars came mostly with a slant six. And the elder people always remember to ask me when they see the DODGE lettering: "You have a six cylinder there, leaning little to the right?"

My goal here is to just to have something differerent and a few horsepower more. I'm not a racer nor do i have a need to go fast anywhere.

I have few rules to my build:

1. It needs to look stock(ish).

2. No fuel injection, just a carb

3. Keep cost low and experiment things

I do not own any special tools, lathes or mills. I have a bad cheapo chinese bench drill though.

Some say that Eaton cannot be used as draw thru setup, but I want to do it anyway.

And the plan is to use stock internals, no forged pistons or anything like that. Just keep the boost somewhere around 5 to 7 psi.

The Car

Here she is as the day I bought her

The view I absolutely love

Pretty original interior, with few rips here and there

Engine bay looked like this. Engine had a poor mans ring job done, but was running very poorly. After a gasket kit to 1bbl Carter, it purred like a kitten. I drove the car like this for couple of summers, but then wanted to do something with it

The Power Plant

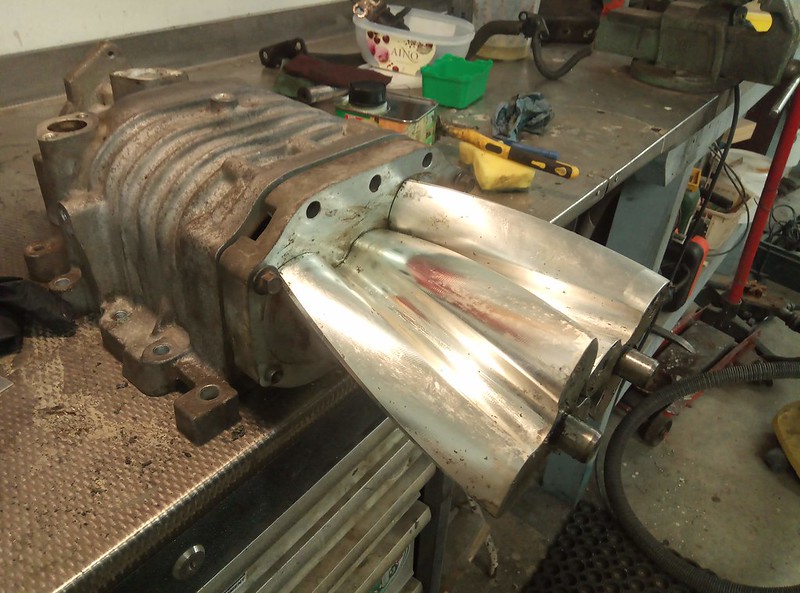

This is my empty mockup motor, that was used to test fit all the parts I was going to fabricate. The Eaton is from 3.8 Buick and bought it from eBay at $140.

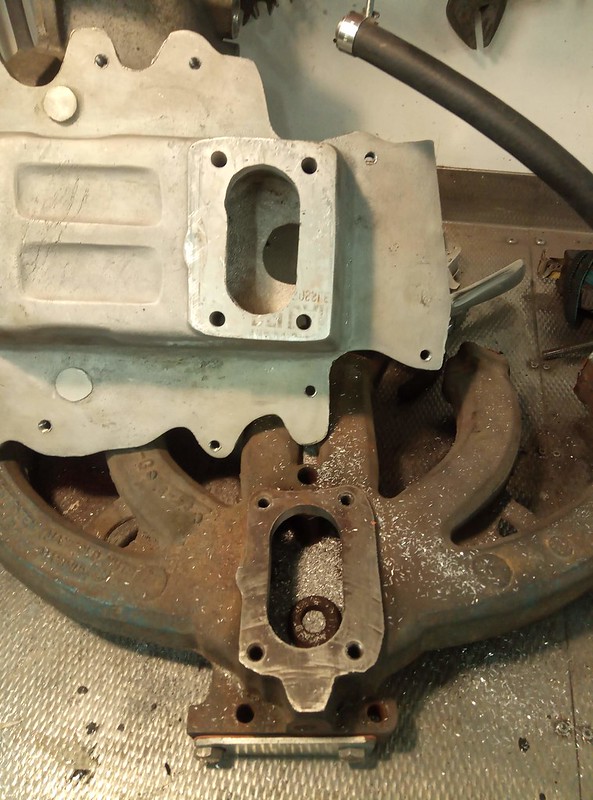

I wanted to use stock 2bbl super intake, rather than fancy ready to bolt on supercharger intake

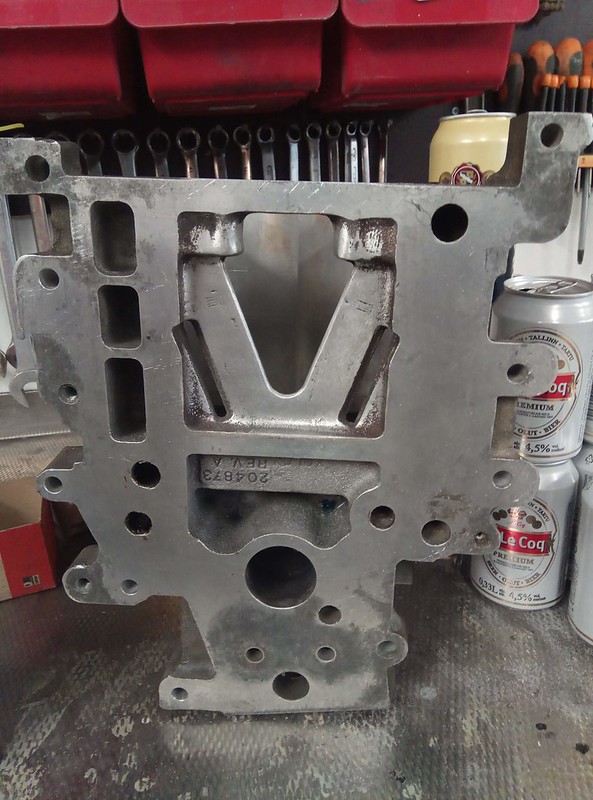

So I started to make adapter between the intake and Eaton. This part involves some wood working, casting sand and some molten aluminium

Here is the mold ready to be poured

And the raw casting right after the pour

Like I said earlier, no special tools available. Just my chinese bench drill

Careful measuring was done to line up the Eaton with crank pulley. My goal was to fit everything under the hood, but soon realized that with this setup it was impossible. The pulley end of Eaton would stick out of the hood line about 3/4 inch

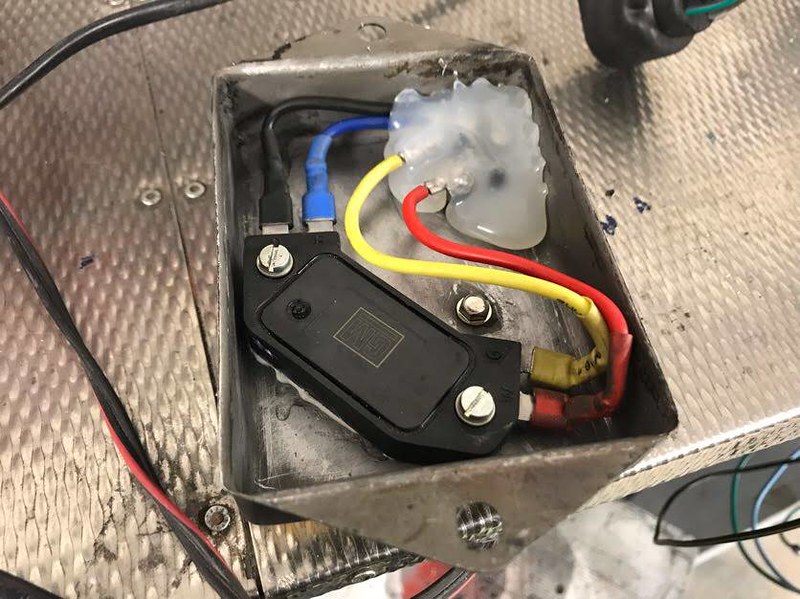

Fuel delivery will be done by this 45mm FAJS side draft carburetor. It's a cheap chinese copy of Weber. All Weber parts will be usable with FAJS. Some say these are bad, but some say these are better machined than Webers.. Who knows...

To attach the carburetor to Eaton, involves some more casting to be done. Here is a foam pattern, going to be casted using the lost foam method

Not all goes as planned always. First pour went to ground and joined the gravel in my yard. There was too little sand under the pattern and the molten aluminium burned through the bottom of my flask

After carving a new pattern, the second pour was a success.

All mating surfaces were hand sanded with a papers glued to piece of stone table top. I could have sent them to a machine shop, but as mentioned earlier I try to keep the costs down. I'm a bit crazy anyway.

Gasket to seal the Eaton to adapter was made from 1mm thick gasket material

O-ring type seals used with the carburetor

Crank serpentine pulley is a March Performance piece for a small block chevy. It's a perfect fit, after drilling the bolt holes just a little bit larger.

This was the first test of belt tensioner locating. Really fast slapped together. Later, I will show you a bit better piece

So, here is a link to my youtube video of the first startup with Eaton setup. It fired up nice, without any usual hick ups.

https://www.youtube.com/watch?v=LzTLjJH4hTM

I have lots of stuff more to show you, if interested. The car is painted different now, hood has a mild scoop, the engine is teared down at the current moment and is at machine shop to be bored. New 2019 model Dutra Duals are waiting in the shelf and so on.

(Edit- Image resizing)