I have seen this topic discussed before on this board (about 12-14 years ago) but the discusion then focused on things like milling and tig and mig and other things I just don't have the tools for.

I spent a few hours and a few dollars converting an Offenhauser intake I got for cheap (thanks again, Wes!) from a single plane intake to a fairly ugly but functional dual plane. This is the cheap and dirty version of the conversion, and I will give you tips on how to do it even easier and cheaper.

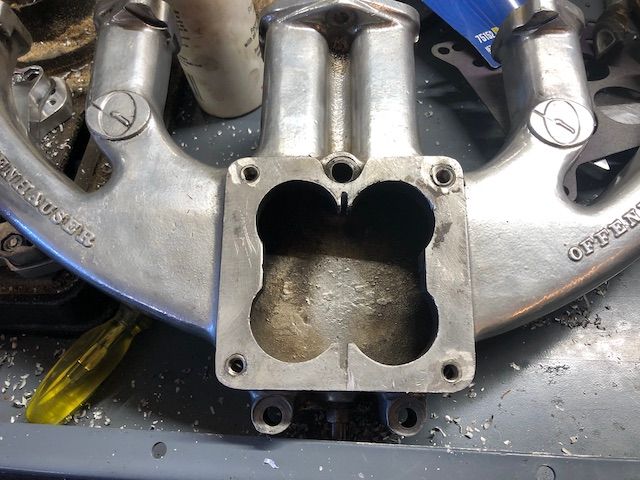

*Note: a previous owner of this intake had it powder coated (oooh, shiny!) and cut the throttle bore + out of the middle of the carb opening. This actually helped me because it gave me easy access to where I needed to place the dividing wall. If your intake has the throttle bore divider still in place you will need to cut the middle part out or cut it all out or make a notch for the divider.

(1) Notch the opening for the intake. Try and get it as wide as possible without cutting into the wall around the central inboard intake-to-exhaust bolt.

(2) Measure and cut/grind (depending on your tools. All I had access to was my bench grinder when I did this) a piece of metal (I used flat steel stock from Home Depot. It was cheap and I already had it) into a dividing wall. Make sure it fills as much of the plenum as possible but is still flush with the carb mounting surface.

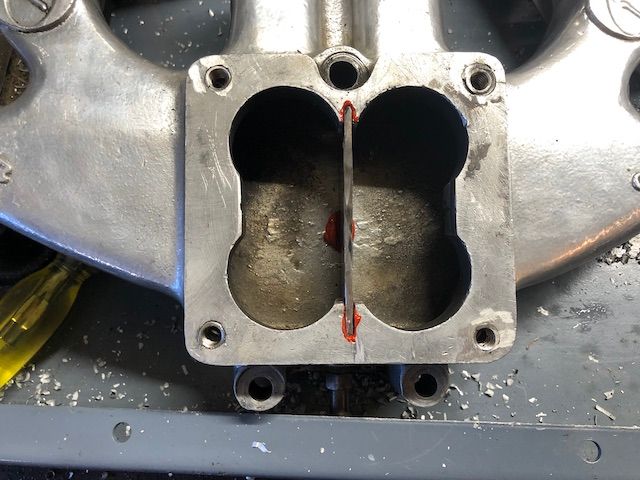

Secure the dividng wall in the intake with some high temp RTV (you want that wall to be removeable in the future "just in case," right?).

(3) There will likely be a gap at the inboard and outboard sections of the divider wall. Fill it with more high temperature RTV.

I left the gap at the back open (a) to serve as sort of a balance tube and (b) because there is a vacuum fitting right behind it that I want to leave functional.

(4) Start building your adapter stack to mount the carb sideways. I did not get any carb mounting plate with this intake so I had to come up with my own as I completed this project. NOTE: If you are using an Offenhauser intake, YOU MUST USE A FOUR HOLE SPACER OR ADAPTER IMMEDIATELY ON TOP OF THE MANIFOLD OR IT WON'T SEAL. The indent for the inboard manifold attachment bolt dips far enough into the plenum area that an open spacer or mounting pad will leave a big vacuum leak.

I started with an old large to small spaced four hole adapter I had and I drilled the holes to match the mounting holes in the intake. This gave me a way to seal the plenum under the carb. I then actually paid to buy a new pair of trick carb mounting adapters that spin the carb 90 degrees while having the carb mounting provisions in the standard location. They are an Edelbrock piece intended for tunnel rams, IIRC. Fortunately, they are sold as a pair in case you mess up the first one. The downside to the 90 degree adapter is that it is an open design. If the 90 degree adapter had been a four hole design, it would have sealed the plenum and I would not have needed the first four-hole adapter.

If you are building your own carb mount from a single piece of aluminum and doing all your own drilling and such, you could get a few four barrel gaskets and carefully mark and drill the carb mounting pad 90 degrees off and skip having to get a second adapter plate. I worked with the materials and tools I had on hand and didn't have that option. I have the hood clearance and want the benefit a carb spacer gives so I don't mind the extra height.

My setup from bottom to top goes: manifold - gasket - four hole spacer in normal orientation - gasket - 90 degree carb adapter screwed to manifold through the four hole adapter and bolted to the four-hole spacer using the normal orientation carb mount holes.

Most expensive part of this was the 90 degree adapters, but I have under $100 into this and now I have a functional "dual-plane" four barrel intake with the carb mounted properly to allow true dual plane operation.

Once I get my rear manifold cut and welded and install my OG Dutra front exhaust manifold, I can run dual O2 sensors and have effectively two three cylinder engines. Should make tuning a bit easier.