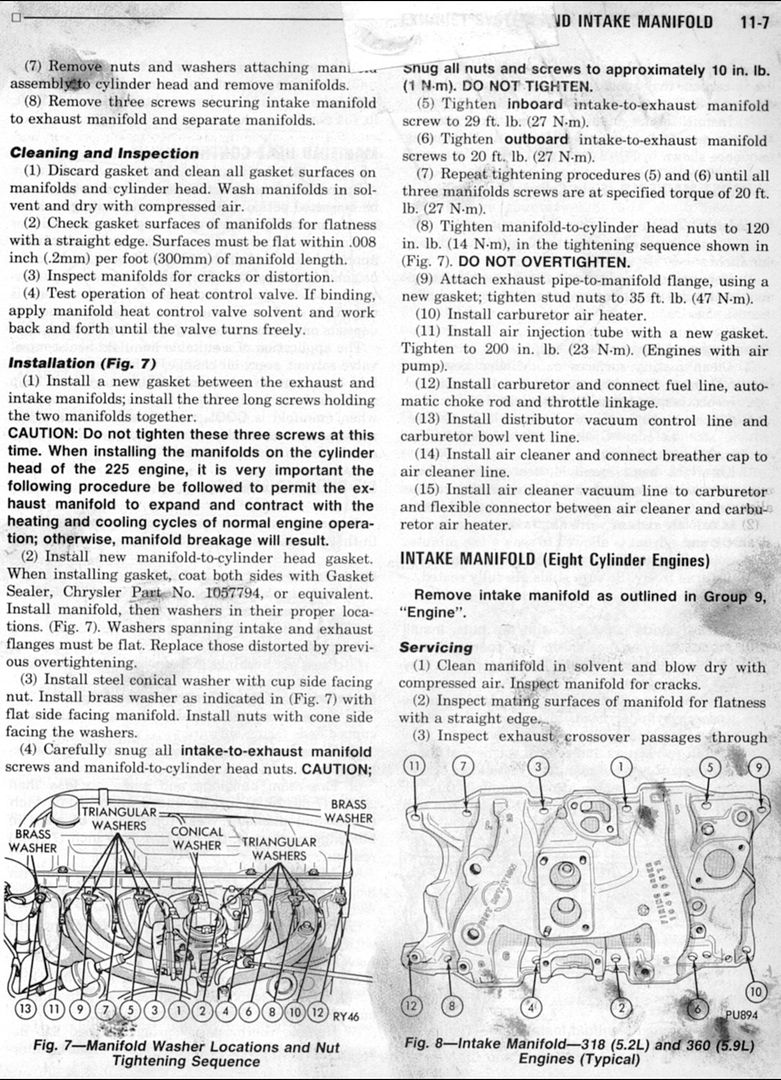

i also have a question about the washers.

i noticed that the triangle, washers have a concave, and a protruding side, i dont remember how these were, which way do they face.

also i have 3 round concave washers, and the rest triangles. i had no brass washers, or any sort of special nuts at all. ive been trying to read all the links given, and im still confused on the complete installation process, which way they go, how many, where to get, everyone seems to be saying different things, im just having quite a bit of trouble